About AAndres

MORE ABOUT AANDRES

First of all, living in a place should provide us with a high quality of life. Thus, the things we surround ourselves by should fit into our lives. If they do not, we won’t feel well. Moreover, we do not feel well when being surrounded by too many things at home either. Things and objects have got their own lives, an own kind of energy. They take or give power. That is what they have got in common with human beings.

Pieces of furniture take a lot of space within a flat. We should select and combine them in a way they do not just have a function but also make us feeling well when being surrounded by them, to make us like them. Like music or a picture we like, they should contribute to our relaxation and flatter our senses.

Furniture should perfectly fulfil the functions and tasks they are built for: Nobody would enjoy having shelves with planks sagging on the third day after assembling. An unsteady table disturbs. Bad varnishing and cheap screws not fulfilling their function are like adulterated wine: brackish.

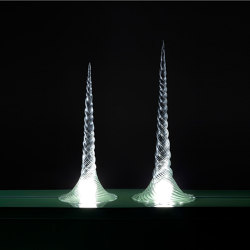

Eileen&Frank is not an ordinary, industrially-produced furniture system: It lives. It breathes. It looks different in different types of light. It is silent. It sparkles. It is reserved and present at the same time. It is individual. It is of premium quality, unobtrusive, noble, and it is a little bit slow at the same time.

It is beautiful.

ENVIRONMENT

We take every effort for a locally-orientated manufacturing process which meets the manifold demands on an environmentally friendly, low-emission production. As expertise and standards concerning environmentally friendly manufacturing are in a continuous state of flux, we make adaptations to our production methods and the materials used wherever this is possible.

Production

We produce 80 % of Eileen&Frank in Switzerland with only the aluminium’s surface finishing being done in Southern Germany. Our factories in Germany and Switzerland are subject to very high ecological standards and inspected regularly.

Whenever possible, we avoid using synthetic and composite materials. All parts and components can be recycled separately.

The following materials are used for our products:

Aluminum

Producing metals and aluminium normally involves a certain degree of environmental pollution. We purchase our aluminium from Alcan in Sierre (Switzerland) as well as from Alu Laufen in Laufen (Switzerland), i.e. from companies having strict environmental specifications. Aluminium is a material which is fully recyclable.

Premium steel

Producing premium steel normally involves a certain degree of environmental pollution. For our screw fittings, we use premium steel in very small amounts only.

Glass

Nowadays, the environmental pollution caused by producing glass is considered to be very small. As a material in everyday use, glass is, furthermore, environmentally harmless and fully recyclable. We purchase the glass used in our products from a Swiss manufacturer.

MDF

If the use of MDF becomes necessary at the request of a customer, for example with coloured-lacquered surface areas, formaldehyde-free MDF made from PEFC™ certified, excorticated coniferous wood is used. MDF is the abbreviation of `medium density fibreboard`, a modern material similar to solid wood as far as weight, the feel of the surface and manufacturing are concerned. We purchase the MDF used for our products from a German producer certified according to the ISO 9001 standards, and we process it here in Switzerland.

Solid wood

We only use wood from environmentally-sensitive cultivation, and we do not use wood from clear cutting. On demand, the solid wood used can also be delivered with a certificate confirming this origin. Our massive wood parts are processed in Switzerland.

Lacquers and oil

For the lacquering of our products, we use environmentally compatible, formaldehyde-free lacquers only. On request, parts from solid wood can be delivered with an oiled surface finish.

Synthetic materials

Whenever possible, we try to do without using plastics. Due to the design, we use four very small components made from polyurethane (PU), a material without any characteristics that might be harmful to health. The share of these four PU components in the product’s total weight is below 0.05 per cent.

Transport

All components are processed in Switzerland and adjoining countries. In the production process, no route of transport is longer than 200 kilometres (only exceptions: wood and MDF). Trucks are used for transportation.

Packaging

The furniture is delivered from our production facilities directly to our costumers. Normally, wooden boxes, felt blankets or cardboard are used as a transport protection. Only in particular cases are polyurethane (PU) rails used as edge guards and recycled later.

Electricity

For our storage and production areas, we use green electricity.

First of all, living in a place should provide us with a high quality of life. Thus, the things we surround ourselves by should fit into our lives. If they do not, we won’t feel well. Moreover, we do not feel well when being surrounded by too many things at home either. Things and objects have got their own lives, an own kind of energy. They take or give power. That is what they have got in common with human beings.

Pieces of furniture take a lot of space within a flat. We should select and combine them in a way they do not just have a function but also make us feeling well when being surrounded by them, to make us like them. Like music or a picture we like, they should contribute to our relaxation and flatter our senses.

Furniture should perfectly fulfil the functions and tasks they are built for: Nobody would enjoy having shelves with planks sagging on the third day after assembling. An unsteady table disturbs. Bad varnishing and cheap screws not fulfilling their function are like adulterated wine: brackish.

Eileen&Frank is not an ordinary, industrially-produced furniture system: It lives. It breathes. It looks different in different types of light. It is silent. It sparkles. It is reserved and present at the same time. It is individual. It is of premium quality, unobtrusive, noble, and it is a little bit slow at the same time.

It is beautiful.

ENVIRONMENT

We take every effort for a locally-orientated manufacturing process which meets the manifold demands on an environmentally friendly, low-emission production. As expertise and standards concerning environmentally friendly manufacturing are in a continuous state of flux, we make adaptations to our production methods and the materials used wherever this is possible.

Production

We produce 80 % of Eileen&Frank in Switzerland with only the aluminium’s surface finishing being done in Southern Germany. Our factories in Germany and Switzerland are subject to very high ecological standards and inspected regularly.

Whenever possible, we avoid using synthetic and composite materials. All parts and components can be recycled separately.

The following materials are used for our products:

Aluminum

Producing metals and aluminium normally involves a certain degree of environmental pollution. We purchase our aluminium from Alcan in Sierre (Switzerland) as well as from Alu Laufen in Laufen (Switzerland), i.e. from companies having strict environmental specifications. Aluminium is a material which is fully recyclable.

Premium steel

Producing premium steel normally involves a certain degree of environmental pollution. For our screw fittings, we use premium steel in very small amounts only.

Glass

Nowadays, the environmental pollution caused by producing glass is considered to be very small. As a material in everyday use, glass is, furthermore, environmentally harmless and fully recyclable. We purchase the glass used in our products from a Swiss manufacturer.

MDF

If the use of MDF becomes necessary at the request of a customer, for example with coloured-lacquered surface areas, formaldehyde-free MDF made from PEFC™ certified, excorticated coniferous wood is used. MDF is the abbreviation of `medium density fibreboard`, a modern material similar to solid wood as far as weight, the feel of the surface and manufacturing are concerned. We purchase the MDF used for our products from a German producer certified according to the ISO 9001 standards, and we process it here in Switzerland.

Solid wood

We only use wood from environmentally-sensitive cultivation, and we do not use wood from clear cutting. On demand, the solid wood used can also be delivered with a certificate confirming this origin. Our massive wood parts are processed in Switzerland.

Lacquers and oil

For the lacquering of our products, we use environmentally compatible, formaldehyde-free lacquers only. On request, parts from solid wood can be delivered with an oiled surface finish.

Synthetic materials

Whenever possible, we try to do without using plastics. Due to the design, we use four very small components made from polyurethane (PU), a material without any characteristics that might be harmful to health. The share of these four PU components in the product’s total weight is below 0.05 per cent.

Transport

All components are processed in Switzerland and adjoining countries. In the production process, no route of transport is longer than 200 kilometres (only exceptions: wood and MDF). Trucks are used for transportation.

Packaging

The furniture is delivered from our production facilities directly to our costumers. Normally, wooden boxes, felt blankets or cardboard are used as a transport protection. Only in particular cases are polyurethane (PU) rails used as edge guards and recycled later.

Electricity

For our storage and production areas, we use green electricity.

MORE ABOUT AANDRES