About MIPA

MORE ABOUT MIPA

ALL BEGINS FROM COLOUR

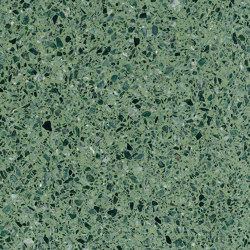

Mipa, a protagonist in the rediscovery of marble Graniglia tiles for floors and wall coverings, combines artisan excellence and industrial quality. It was with passion and determination, together with a joint commitment to this cultural project and involvement by all the members of the company, that brought to fruition the rediscovery and re-evaluation of Graniglia floors.

From its very conception, Mipa activated the recovery of the original cast bronze moulds from the scattering of antique manufacturing sites that had been left abandoned throughout the Italian peninsula. As such, the same original moulds that once upon a time were used to create the decorative tiles that enhanced aristocratic homes, were recovered and restored. Mipa also sought to understand, by speaking to the original craftsmen, the secrets of the body mixes. Those same secrets that held the recipe for the raw ingredients of water, marble granules and chips, cement and natural oxide colorants.

Today Mipa may say with pride that it has succeeded in restoring Marble Terrazzo to its original glory, by following the path of research into history and style and by remaining faithful to traditional production techniques, without reverting to processes that could compromise the technical, aesthetic and qualitative properties of the final product.

Each day at Mipa expert hands, using copper ladles, work the liquid body mix, then fill the bronze moulds that will reproduce the decorative tiles. It is in this way that something truly original is created, reinventing itself every time with authentic forms, lines and colours, but always faithful to the secrets of one of the most refined artistic traditions.

Replaced by Mipa in that prestigious position it had lost in the national memory, Graniglia has made possible the restoration of prestigious historic buildings. In this way a worldwide cultural heritage has been preserved from oblivion, once again becoming protagonist of the contemporary taste.

Artisan excellence and industrial quality

Natural raw materials and environmentally-friendly processing produce unique top-performance handicrafts products with high tech-contents fully produced in Italy.

It is a new and exclusive dimension, an original and distinctive vision that turns marble Graniglia tiles into design products enriching and enhancing any environment.

MANUFACTURING

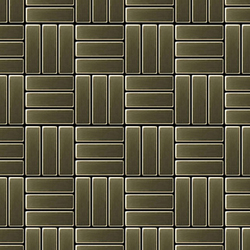

All ingredients are natural: marble granules and chips, white cement, natural oxides.

Mipa’s role is to merely select those ingredients and the selection process is both difficult and crucial and absolutely necessary to ensure the highest aesthetic and performance standards.

The formulation of the body mix is achieved by the choice of bonding agents (top-quality white cement), the water-cement ratio and the inert characteristics of marble.

The Mipa body mix is at first mixed using devices adapted from the pharmaceutical industry, then it is vibrated at a predetermined frequency, compacted using high pressure and then, and most importantly, all excess water and air is removed using highly advanced technological processes. It is then seasoned in special cells with temperature and humidity numerical control.

The removal of water and air markedly reduces the porosity and as a result Marble Terrazzo tiles are more resistant to staining and marking. The same process increases enormously the mechanical-physical performance and allows for the formation of “full body” tiles with a thickness of 11 mm.

As a result the range of applications for Marble Terrazzo tiles has been notably expanded.

At Mipa we are committed to the journey that we have undertaken a journey that seeks to exalt, through design and production techniques, the Graniglia culture.

Alongside this original concept we are committed to offering new forms and designs that one by one will reveal the enormous aesthetic potential and previously unseen versatility of a product that will enhance our daily lives.

THE FUTURE LIKE YOU HAVE NEVER SEEN IT

Production and consumption systems are changing increasingly. There is a resumption of consumption connected to a product’s ability to tell its own story, i.e. the history of production and the relevant identity, cultural and work values playing a role both ethically and socially.

This is the true meaning of an expression like “made in Italy”, which has often been overexploited, i.e. the search for an authentic approach to excellent artisan skills aimed at designing and manufacturing products.

Material cultural values derive from the ability to add aesthetic value by processing raw materials (natural materials, i.e. 80% precious and selected, pre-washed, dusted, marble with selected granulometry).

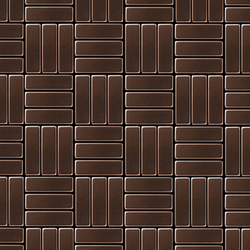

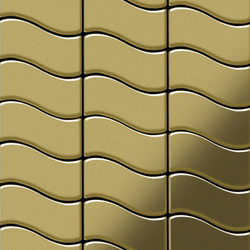

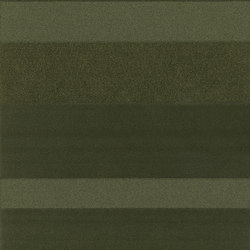

The MIPA offer is a bridge between the world of materials (Liberty and Art Déco decorations and colours at the turn of the 20th Century), with their possible implementation in processes deriving from the recovery of historical buildings (both in terms of colour customisation and versatility: materials may be used in both floors and walls, indoor and outdoor, leading to glossy, matt or brushed effects), and the world of contemporary design (in which the company has invested heavily and obtained a large number of awards and prizes).

Those design and manufacturing skills have found their perfect complements in the range of services supplied by the company through its website: an internet platform, in addition to providing a detailed presentation of the product range, also gives access to a customised product design interface.

This leads to a real tailor made production process meeting all customer’s needs (upon request, colour palettes may be activated and original customised patterns may be implemented on 20x20 formats).

Moreover, formats may be customised (starting from cm. 20x20, 40x40 and 60x60 standard formats) to develop special products and formats by processing slabs measuring approximately cm. 250x125 (consequently, floors and walls may be integrated with sinks, shelves, staircases and customised products in general).

The experimental side of research on materials led to prestigious collaborations projects with the Research & Development departments of the most important players in this sector, such as MAPEI and ITALCEMENTI and the Faculty of Engineering of the University of Modena and Reggio Emilia.

The initiatives taken enabled MIPA to be the first to propose pre-finished single-layer materials with reduced thickness compared to traditional products (to be able to use marble chip tiles also for wall covers). This implied greatly improved performance by products in terms of their installation and maintenance, leading to markedly better technical features than traditional products, with halved weight.

A bridge between past and present, a tradition that is constantly renewed while maintaining the heritage of past models, a concrete approach that is both advanced and visionary at the same time, faithful to production skills but open to imagination and experiments, all derive from the vision of a future deriving from the past, opening up new horizons with stubborn humility.

ALL BEGINS FROM COLOUR

Mipa, a protagonist in the rediscovery of marble Graniglia tiles for floors and wall coverings, combines artisan excellence and industrial quality. It was with passion and determination, together with a joint commitment to this cultural project and involvement by all the members of the company, that brought to fruition the rediscovery and re-evaluation of Graniglia floors.

From its very conception, Mipa activated the recovery of the original cast bronze moulds from the scattering of antique manufacturing sites that had been left abandoned throughout the Italian peninsula. As such, the same original moulds that once upon a time were used to create the decorative tiles that enhanced aristocratic homes, were recovered and restored. Mipa also sought to understand, by speaking to the original craftsmen, the secrets of the body mixes. Those same secrets that held the recipe for the raw ingredients of water, marble granules and chips, cement and natural oxide colorants.

Today Mipa may say with pride that it has succeeded in restoring Marble Terrazzo to its original glory, by following the path of research into history and style and by remaining faithful to traditional production techniques, without reverting to processes that could compromise the technical, aesthetic and qualitative properties of the final product.

Each day at Mipa expert hands, using copper ladles, work the liquid body mix, then fill the bronze moulds that will reproduce the decorative tiles. It is in this way that something truly original is created, reinventing itself every time with authentic forms, lines and colours, but always faithful to the secrets of one of the most refined artistic traditions.

Replaced by Mipa in that prestigious position it had lost in the national memory, Graniglia has made possible the restoration of prestigious historic buildings. In this way a worldwide cultural heritage has been preserved from oblivion, once again becoming protagonist of the contemporary taste.

Artisan excellence and industrial quality

Natural raw materials and environmentally-friendly processing produce unique top-performance handicrafts products with high tech-contents fully produced in Italy.

It is a new and exclusive dimension, an original and distinctive vision that turns marble Graniglia tiles into design products enriching and enhancing any environment.

MANUFACTURING

All ingredients are natural: marble granules and chips, white cement, natural oxides.

Mipa’s role is to merely select those ingredients and the selection process is both difficult and crucial and absolutely necessary to ensure the highest aesthetic and performance standards.

The formulation of the body mix is achieved by the choice of bonding agents (top-quality white cement), the water-cement ratio and the inert characteristics of marble.

The Mipa body mix is at first mixed using devices adapted from the pharmaceutical industry, then it is vibrated at a predetermined frequency, compacted using high pressure and then, and most importantly, all excess water and air is removed using highly advanced technological processes. It is then seasoned in special cells with temperature and humidity numerical control.

The removal of water and air markedly reduces the porosity and as a result Marble Terrazzo tiles are more resistant to staining and marking. The same process increases enormously the mechanical-physical performance and allows for the formation of “full body” tiles with a thickness of 11 mm.

As a result the range of applications for Marble Terrazzo tiles has been notably expanded.

At Mipa we are committed to the journey that we have undertaken a journey that seeks to exalt, through design and production techniques, the Graniglia culture.

Alongside this original concept we are committed to offering new forms and designs that one by one will reveal the enormous aesthetic potential and previously unseen versatility of a product that will enhance our daily lives.

THE FUTURE LIKE YOU HAVE NEVER SEEN IT

Production and consumption systems are changing increasingly. There is a resumption of consumption connected to a product’s ability to tell its own story, i.e. the history of production and the relevant identity, cultural and work values playing a role both ethically and socially.

This is the true meaning of an expression like “made in Italy”, which has often been overexploited, i.e. the search for an authentic approach to excellent artisan skills aimed at designing and manufacturing products.

Material cultural values derive from the ability to add aesthetic value by processing raw materials (natural materials, i.e. 80% precious and selected, pre-washed, dusted, marble with selected granulometry).

The MIPA offer is a bridge between the world of materials (Liberty and Art Déco decorations and colours at the turn of the 20th Century), with their possible implementation in processes deriving from the recovery of historical buildings (both in terms of colour customisation and versatility: materials may be used in both floors and walls, indoor and outdoor, leading to glossy, matt or brushed effects), and the world of contemporary design (in which the company has invested heavily and obtained a large number of awards and prizes).

Those design and manufacturing skills have found their perfect complements in the range of services supplied by the company through its website: an internet platform, in addition to providing a detailed presentation of the product range, also gives access to a customised product design interface.

This leads to a real tailor made production process meeting all customer’s needs (upon request, colour palettes may be activated and original customised patterns may be implemented on 20x20 formats).

Moreover, formats may be customised (starting from cm. 20x20, 40x40 and 60x60 standard formats) to develop special products and formats by processing slabs measuring approximately cm. 250x125 (consequently, floors and walls may be integrated with sinks, shelves, staircases and customised products in general).

The experimental side of research on materials led to prestigious collaborations projects with the Research & Development departments of the most important players in this sector, such as MAPEI and ITALCEMENTI and the Faculty of Engineering of the University of Modena and Reggio Emilia.

The initiatives taken enabled MIPA to be the first to propose pre-finished single-layer materials with reduced thickness compared to traditional products (to be able to use marble chip tiles also for wall covers). This implied greatly improved performance by products in terms of their installation and maintenance, leading to markedly better technical features than traditional products, with halved weight.

A bridge between past and present, a tradition that is constantly renewed while maintaining the heritage of past models, a concrete approach that is both advanced and visionary at the same time, faithful to production skills but open to imagination and experiments, all derive from the vision of a future deriving from the past, opening up new horizons with stubborn humility.

MORE ABOUT MIPA