About Parklex Prodema

MORE ABOUT PARKLEX PRODEMA

Quality, innovation and collaboration.

Since 1968, Parklex has provided architects, decorators, master builders and builders with a wide range of solutions with their products manufactured from natural wood for use in facings, flooring and ceilings. Parklex is a dynamic company on the cutting edge, with a professional team focused on the needs of their clients.

Quality

Since Parklex is a product that can be used in both interiors and exteriors, it is subjected to constant wear from sunlight, humidity and abrasion in traffic areas. This is why a large part of the effort and investment in the area of R&D is spent on guaranteeing the durability and material stability of Parklex facings.

Innovation

The materials used consist of resins, fibers and natural wood laminates, the product of the most advanced technology and combined with cutting-edge innovation, in accordance with current architectural trends.

Collaboration

The result of its history of collaborating with architects, master builders and designers, Parklex today has earned the trust of nationally and internationally renowned architects who use Parklex in their most emblematic works.

History

1966

Maderas Gurea, S.A. is founded.

1985

Company changes its name to Composites Gurea, S.A.

1992

Beginning of the Parklex development (wood application for construction).

1993

First Parklex project as a floating floor.

1994

First use of Parklex as a façade facing.

1997

Inauguration of the Guggenheim Museum in Bilbao, with 4,000 m2 of floating floors.

2000

Inauguration of the new installations.

2003

AENOR certification, according to UNE EN ISO 9002.

2006

Certification according to EN 438.

Environmentally responsible production.

Aware of the importance of caring for the environment through responsible, sustainable production, Parklex has earned the PEFC certificate.

This prestigious chain of custody certification is a guarantee that Parklex is collaborating in the sustainable maintenance and improvement of the forests and the environment.

With this certification, Parklex demonstrates its commitment to responsible, nature-friendly growth. In addition, all innovations included in new product lines that are launched adhere to this philosophy of respect for the environment and sustainable production, which guarantees that resources will be available for many years to come.

Constant dedication to providing a good product.

Production process.

Each type of Parklex is subjected to a different production process, depending on its final application: interiors, exteriors, damp areas, etc.

The base is always high-density laminated wood with a paper fiber core that has been treated with thermosetting resins and compressed at high pressure and temperature.

Natural wood.

The surface is always made from 100% natural wood, treated according to its application: to resist special weather conditions or to perfectly resist the intensive use it might receive in interiors.

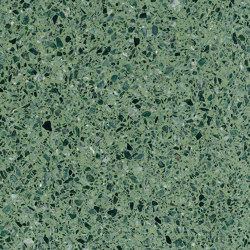

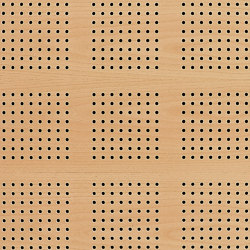

Finishes.

Perfect adaptation to the project design is an essential requirement. That’s why the technology used to manufacture Parklex allows us to apply different finishes, all in natural wood, to integrate them completely into the environment that is required for each project.

Range.

The variety of finishes and colors in natural and dyed panels sets Parklex apart as a result of its versatility, making it the ideal covering from any type of project.

International.

Providing service on an international level has meant establishing an extensive network of Parklex distributors on all five continents. This allows us to work more closely with our clients and offer them better service in a way that is more accessible to them. It also lets us understand their needs perfectly and first hand.

Guarantees / Quality Certificates.

Rigorous testing guarantees Parklex’s excellent performance.

Architects.

The best architects in the world use Parklex in their most emblematic creations. Why is this so?

Because they feel comfortable and at ease, and because the results do not disappoint them. Without a doubt, it is because at Parklex we have been working for over 15 years on a daily basis with architects from all over the world, including, for example, Santiago Calatrava, Frank Gehry, Norman Foster, Jean Nouvel and Nicholas Grimshaw, adapting our range to their requirements. This has made Parklex the natural wood covering of choice in many of the best quality and best-known projects in the world.

This can only be achieved by a brand with an absolute guarantee, capable of offering the perfect product, totally adapted to their needs, with problem-free application.

Quality, innovation and collaboration.

Since 1968, Parklex has provided architects, decorators, master builders and builders with a wide range of solutions with their products manufactured from natural wood for use in facings, flooring and ceilings. Parklex is a dynamic company on the cutting edge, with a professional team focused on the needs of their clients.

Quality

Since Parklex is a product that can be used in both interiors and exteriors, it is subjected to constant wear from sunlight, humidity and abrasion in traffic areas. This is why a large part of the effort and investment in the area of R&D is spent on guaranteeing the durability and material stability of Parklex facings.

Innovation

The materials used consist of resins, fibers and natural wood laminates, the product of the most advanced technology and combined with cutting-edge innovation, in accordance with current architectural trends.

Collaboration

The result of its history of collaborating with architects, master builders and designers, Parklex today has earned the trust of nationally and internationally renowned architects who use Parklex in their most emblematic works.

History

1966

Maderas Gurea, S.A. is founded.

1985

Company changes its name to Composites Gurea, S.A.

1992

Beginning of the Parklex development (wood application for construction).

1993

First Parklex project as a floating floor.

1994

First use of Parklex as a façade facing.

1997

Inauguration of the Guggenheim Museum in Bilbao, with 4,000 m2 of floating floors.

2000

Inauguration of the new installations.

2003

AENOR certification, according to UNE EN ISO 9002.

2006

Certification according to EN 438.

Environmentally responsible production.

Aware of the importance of caring for the environment through responsible, sustainable production, Parklex has earned the PEFC certificate.

This prestigious chain of custody certification is a guarantee that Parklex is collaborating in the sustainable maintenance and improvement of the forests and the environment.

With this certification, Parklex demonstrates its commitment to responsible, nature-friendly growth. In addition, all innovations included in new product lines that are launched adhere to this philosophy of respect for the environment and sustainable production, which guarantees that resources will be available for many years to come.

Constant dedication to providing a good product.

Production process.

Each type of Parklex is subjected to a different production process, depending on its final application: interiors, exteriors, damp areas, etc.

The base is always high-density laminated wood with a paper fiber core that has been treated with thermosetting resins and compressed at high pressure and temperature.

Natural wood.

The surface is always made from 100% natural wood, treated according to its application: to resist special weather conditions or to perfectly resist the intensive use it might receive in interiors.

Finishes.

Perfect adaptation to the project design is an essential requirement. That’s why the technology used to manufacture Parklex allows us to apply different finishes, all in natural wood, to integrate them completely into the environment that is required for each project.

Range.

The variety of finishes and colors in natural and dyed panels sets Parklex apart as a result of its versatility, making it the ideal covering from any type of project.

International.

Providing service on an international level has meant establishing an extensive network of Parklex distributors on all five continents. This allows us to work more closely with our clients and offer them better service in a way that is more accessible to them. It also lets us understand their needs perfectly and first hand.

Guarantees / Quality Certificates.

Rigorous testing guarantees Parklex’s excellent performance.

Architects.

The best architects in the world use Parklex in their most emblematic creations. Why is this so?

Because they feel comfortable and at ease, and because the results do not disappoint them. Without a doubt, it is because at Parklex we have been working for over 15 years on a daily basis with architects from all over the world, including, for example, Santiago Calatrava, Frank Gehry, Norman Foster, Jean Nouvel and Nicholas Grimshaw, adapting our range to their requirements. This has made Parklex the natural wood covering of choice in many of the best quality and best-known projects in the world.

This can only be achieved by a brand with an absolute guarantee, capable of offering the perfect product, totally adapted to their needs, with problem-free application.

MORE ABOUT PARKLEX PRODEMA