About Casalgrande Padana

MORE ABOUT CASALGRANDE PADANA

Casalgrande Padana has been producing advanced ceramic materials for over 50 years: innovative and environment-friendly solutions for the creation of coatings, floors and coatings capable of responding to any creative and technological requirement of the world of architecture and design.

100% made in italy

“we are proud of what we produce”

Casalgrande Padana is currently the first company that focused its production on porcelain stoneware. We have adopted an industrial policy strongly oriented to promote technological innovation and the protection of the environment. We operate through an intense research and experimentation activity for the continuous improvement of the product both as to aesthetics and performance. We develop, produce and innovate in our sites and laboratories entirely based in Italy.

Our objective is excellence

All the steps of the process are constantly monitored: from the choice of raw materials to their storage, grinding of the mixture, shaping and firing of the tiles; from the manufacturing process to product quality control; from the preparation of accurate technical information to an effective support service for professionals: everything proves the great effort we dedicate to improve our manufacturing processes and search for excellence.

Solutions, not products

Consisting exclusively of natural raw materials, Casalgrande Padana’s porcelain stoneware is obtained by implementing a closed-cycle process that stands out among our competitors for a minimized environmental impact.

The ceramic products we propose go far beyond the usual market offer and can fulfil all application requirements both in terms of functions and types of buildings. But our offer does not only concern products.

We place a great importance on providing support services like design consulting with the aim of achieving the maximum installation and architectural quality.

an offer that has no comparisons

- Floors and facings for architecture and interior design

- Ceramic coating for external surfaces

- Ventilated façades

- Insulation systems with thin slabs

- Shading systems with ceramic slabs or tubular components

- Indoor bioactive anti-bacterial floors and tiled surfaces

- Bioactive self-cleaning and anti-bacterial surface coatings

- Dry self-laying floors

- Raised and floating floors

- Industrial flooring

- Multi-sensory floors to guide visually impaired people

- Special coatings and pieces for swimming-pools

our values

“we innovate with sensitivity and respect. Knowledge and technology alone are not enough”

Producing advanced ceramic materials in a correct balance between respect of natural resources, protection of the environment, technological progress, economic growth and social accountability are all deeply-rooted values in Casalgrande Padana’s DNA. In the awareness of the importance of a balanced growth, we boast a cycle where each processing step is characterised by a search for excellence, the use of industrial systems and procedures inspired to environment protection and energy efficiency policies definitely oriented to sustainability. Being “green” is taken for granted today - this is why Casalgrande Padana has chosen to do much more than that.

100% virtuous

Our production process is a closed-cycle where all the processing waste, including waste water, is treated and reused.

By means of special systems, all the components are recycled and completely recovered.

The emissions produced by the production process are purified by lime treatment systems using the best technologies to transform fluoride into an inert substance, which allow us to largely fulfil the limits established by the law. Casalgrande Padana’s environmental

policy is also implemented by using Green Procurement criteria to favour the selection of sustainable suppliers and reduce the impact on the environment upstream our activities and products.

Our energy is your energy

Casalgrande Padana’s energy policy is oriented to the respect for the environment, the containment of consumption and maximization of yields. We use methane gas to fire our kilns because it is one of the fossil fuels with the lower environmental impact. All our premises are heated with systems that recover heat from the kilns by using air/ air heat exchangers for the plants and air/water heat exchangers for the offices and changing rooms. The self-production of energy is ensured by the operation of a highly efficient methane cogeneration power plant (1,000 kWh for 5,000 hours of operation per year), which associates a gas turbine to an atomizer. This system allows for the best possible use of the entire potential available, which consists of electricity for 25% and thermal energy which would otherwise be lost for the remaining 75%. The electricity produced with this method covers 35% of the requirement of the entire plant, while the hot air generated by the turbine us reused in the drier. Thanks to the considerable optimization of the process, we reach yields close to 100% - an excellent result if compared to the 40% yield of a traditional turbine system. The whole of the actions and strategies implemented has allowed us to achieve significant results in terms of energy efficiency, rationalization of technological processes and use of primary fuels, with a remarkable reduction of the implications for the environment. This is the proof of how Casalgrande Padana shows extreme sensitivity and responsibility vis-à-vis the needs and wellbeing of the entire surrounding community.

the courage of crossing borders

“a true leader does not merely indicate a direction: he takes it”

Focus on the requirements of projects, building sites, and companies; opportunities offered by technological innovation and the needs of a growth that starts from sustainable development; the willingness and initiative of looking for answers that go beyond the usual borders... these have always been the guiding principles of Casalgrande Padana’s research activity. By interpreting these drivers, our company has defined new concepts and types of application, thus opening unexplored market areas and developing innovative solutions in terms of raw materials and processing cycles. These experiences today have defined new best practices for the entire industry.

Bioactive ceramics

Casalgrande Padana is a leader and undisputable forerunner in the industry. Bioactive ceramics are an innovative type of eco- compatible products that can autonomously interface with the environment to generate a series of virtuous processes.

The independent research programs that have been promoted in cooperation with the Department of Biomedical Sciences, Microbiology Section, of the University of Modena and Reggio Emilia, combined with the Master Agreement with the Japanese group “TOTO” (a pioneer in photo-catalytic technology with the HYDROTECT® brand), have led to the production of a new and exclusive generation of ceramic products for architecture.

To date, nobody else can offer such a complete range of high- performance products.

Casalgrande Padana’s offer includes:

Bios Self-Cleaning Ceramics®, a line of ceramic slabs for the installation of façade coatings capable of abating the pollutants in the air and decompose the dirt that deposits on their surfaces, which are therefore self-cleaning.

Bios Antibacterial Ceramics®, a line of ceramic slabs for floors and coating applications characterised by absolute anti-bacterial properties, which includes two types of products:

Bios Antibacterial HYDROTECT®, slabs that combine the anti- bacterial properties of noble metals with those of titanium dioxide, thus making the tiles capable of eliminating bacteria and bad smells even in conditions of complete absence of light.

This treatment is done on request on all the series of Casalgrande Padana’s catalogue; Bios Antibacterial GRANITOGRES®, lslabs that exploit the properties of an innovative anti-bacterial treatment with silver, capable of eliminating the main bacterial strains even in conditions of complete absence of light.

This treatment is applied to the mass of the tiles and is wear-resistant, so it is perfect for high-traffic conditions. The treatment is done on request, exclusively on the Granitogres line products.

The many international recognitions of Casalgrande Padana include the selection for ADI Design Index 2010; AIT Innovation Award 2010 “Architecture and Building”; AIT Innovation Award 2010 “Architecture and Flooring”; Produkt des Jahres 2011 (ranked 3rd) Fliesen Platten Leserwahl; Iconic Awards 2013.

Tactile® System

To meet the autonomy and safety requirements of visually impaired and elderly people and guide them along their paths both outdoor and in public or confined indoor spaces, Casalgrande Padana developed the Tactile® System (patent no. 00237769), a special kind of fine Granitogres porcelain stoneware tiles on which a special signalling language has been imprinted.

The elements of the modular floor are categorised based on simple-to-understand information codes that are linked to specific 3D and colour codes that mark stop lines, steps, crossings and deviations. Among the many international recognitions: the first prize of the “Soliditas Social Award 2006” and the “Good Design Award 2009”.

solutions for architecture

“our skills to serve your ideas”

Casalgrande Padana has been identified as the ideal partner by thousands of designers and clients worldwide thanks to the uniqueness of our products, to the expertise gained in over 50 years of activity in all sorts of constructions and architectures of all scales, types and final uses, to the capacity of offering a competent consulting service through Padana Engineering - a company specialising in the supply of support services for each step of the work, from the selection of materials to project development, tile laying and final testing. The culture of production and the culture of design have always been our cornerstones along a path of strong commitment to provide premium proposals, from the promotion of architecture projects to design and culture, publishing, art and support to important restoration work.

Grand Prix

International architecture competition

At its tenth edition this year, Grand Prix is an international architecture competition conceived and promoted in 1990 by Casalgrande Padana with the purpose of selecting and awarding the most significant projects that used porcelain stoneware materials of its own production. Through this cultural initiative, the company, which has always been particularly interested and focused on novelties and innovative ideas regarding the international architecture scenario, has promoted an event where ceramic shows all its strength, flexibility and eclecticism in various fields of the building industry - an event where tiles are not one of the many aspects, but the absolute protagonists of a project.

Creative Book and Casabella

Casalgrande Padana has consolidated its privileged relationship with designers by promoting a number of actions in support of the Grand Prix event, where it took care of a well-focused and efficient communication through meetings, conferences and publications. One of the most significant actions, in this regard, has been the cooperation with the international architecture magazine “Casabella”, which proactively works with Casalgrande Padana at developing the Grand Prix project. Starting from 2001, Casabella and Casalgrande Padana have collaborated at the production of the Creative Book, a professional updating tool that is attached to the magazine to disseminate the results of each Grand Prix edition.

Cooperate for innovation

During the course of its long business activity, Casalgrande Padana has started many cooperation relationships with important authors of the world of architecture and design, in order to develop very peculiar lines of research that have led to the construction of important works, as well as to the creation of innovative types of ceramic slabs and products. Among the most recent projects, we may mention those conducted with Kengo Kuma, the author of the spectacular architecture installation called “Casalgrande Ceramic Cloud” and the restoration of the museum-house “Old House”; the façade systems for the City Life Residences, the Pinnacle installation, the Vanke pavilion for Expo 2015 and a series of new tiles, designed by Daniel Libeskind; and again, the special polychromatic pieces for the outer surfaces of the MAST (Manifattura di Arte, Sperimentazione e Tecnologia) nursery in Bologna, a work by Studio Labics, where Bios Antibacterial GRANITOGRES® materials have also been used for tiling of the kitchen; the new ceramic slab series and 3D elements developed with the 5+1AA architecture agents Alfonso Femia, Gianluca Peluffo.

A pole for creativity

In order to give a tangible support to the partnerships with all the people who have a role in translating creativity into built architecture, Casalgrande Padana, based on a project of “Studio Cerri Associati Engineering”, developed the Creative Centre, a sustainable space open to the professionals of the sector, dedicated to design and training.

The Centre has been conceived as a place where a direct contact is established with the factory to spur interactions between innovation and creativity by combining exhibitions, communication, technical information and laboratory activities in the fields of architecture, design and manufacturing.

Casalgrande Padana has been producing advanced ceramic materials for over 50 years: innovative and environment-friendly solutions for the creation of coatings, floors and coatings capable of responding to any creative and technological requirement of the world of architecture and design.

100% made in italy

“we are proud of what we produce”

Casalgrande Padana is currently the first company that focused its production on porcelain stoneware. We have adopted an industrial policy strongly oriented to promote technological innovation and the protection of the environment. We operate through an intense research and experimentation activity for the continuous improvement of the product both as to aesthetics and performance. We develop, produce and innovate in our sites and laboratories entirely based in Italy.

Our objective is excellence

All the steps of the process are constantly monitored: from the choice of raw materials to their storage, grinding of the mixture, shaping and firing of the tiles; from the manufacturing process to product quality control; from the preparation of accurate technical information to an effective support service for professionals: everything proves the great effort we dedicate to improve our manufacturing processes and search for excellence.

Solutions, not products

Consisting exclusively of natural raw materials, Casalgrande Padana’s porcelain stoneware is obtained by implementing a closed-cycle process that stands out among our competitors for a minimized environmental impact.

The ceramic products we propose go far beyond the usual market offer and can fulfil all application requirements both in terms of functions and types of buildings. But our offer does not only concern products.

We place a great importance on providing support services like design consulting with the aim of achieving the maximum installation and architectural quality.

an offer that has no comparisons

- Floors and facings for architecture and interior design

- Ceramic coating for external surfaces

- Ventilated façades

- Insulation systems with thin slabs

- Shading systems with ceramic slabs or tubular components

- Indoor bioactive anti-bacterial floors and tiled surfaces

- Bioactive self-cleaning and anti-bacterial surface coatings

- Dry self-laying floors

- Raised and floating floors

- Industrial flooring

- Multi-sensory floors to guide visually impaired people

- Special coatings and pieces for swimming-pools

our values

“we innovate with sensitivity and respect. Knowledge and technology alone are not enough”

Producing advanced ceramic materials in a correct balance between respect of natural resources, protection of the environment, technological progress, economic growth and social accountability are all deeply-rooted values in Casalgrande Padana’s DNA. In the awareness of the importance of a balanced growth, we boast a cycle where each processing step is characterised by a search for excellence, the use of industrial systems and procedures inspired to environment protection and energy efficiency policies definitely oriented to sustainability. Being “green” is taken for granted today - this is why Casalgrande Padana has chosen to do much more than that.

100% virtuous

Our production process is a closed-cycle where all the processing waste, including waste water, is treated and reused.

By means of special systems, all the components are recycled and completely recovered.

The emissions produced by the production process are purified by lime treatment systems using the best technologies to transform fluoride into an inert substance, which allow us to largely fulfil the limits established by the law. Casalgrande Padana’s environmental

policy is also implemented by using Green Procurement criteria to favour the selection of sustainable suppliers and reduce the impact on the environment upstream our activities and products.

Our energy is your energy

Casalgrande Padana’s energy policy is oriented to the respect for the environment, the containment of consumption and maximization of yields. We use methane gas to fire our kilns because it is one of the fossil fuels with the lower environmental impact. All our premises are heated with systems that recover heat from the kilns by using air/ air heat exchangers for the plants and air/water heat exchangers for the offices and changing rooms. The self-production of energy is ensured by the operation of a highly efficient methane cogeneration power plant (1,000 kWh for 5,000 hours of operation per year), which associates a gas turbine to an atomizer. This system allows for the best possible use of the entire potential available, which consists of electricity for 25% and thermal energy which would otherwise be lost for the remaining 75%. The electricity produced with this method covers 35% of the requirement of the entire plant, while the hot air generated by the turbine us reused in the drier. Thanks to the considerable optimization of the process, we reach yields close to 100% - an excellent result if compared to the 40% yield of a traditional turbine system. The whole of the actions and strategies implemented has allowed us to achieve significant results in terms of energy efficiency, rationalization of technological processes and use of primary fuels, with a remarkable reduction of the implications for the environment. This is the proof of how Casalgrande Padana shows extreme sensitivity and responsibility vis-à-vis the needs and wellbeing of the entire surrounding community.

the courage of crossing borders

“a true leader does not merely indicate a direction: he takes it”

Focus on the requirements of projects, building sites, and companies; opportunities offered by technological innovation and the needs of a growth that starts from sustainable development; the willingness and initiative of looking for answers that go beyond the usual borders... these have always been the guiding principles of Casalgrande Padana’s research activity. By interpreting these drivers, our company has defined new concepts and types of application, thus opening unexplored market areas and developing innovative solutions in terms of raw materials and processing cycles. These experiences today have defined new best practices for the entire industry.

Bioactive ceramics

Casalgrande Padana is a leader and undisputable forerunner in the industry. Bioactive ceramics are an innovative type of eco- compatible products that can autonomously interface with the environment to generate a series of virtuous processes.

The independent research programs that have been promoted in cooperation with the Department of Biomedical Sciences, Microbiology Section, of the University of Modena and Reggio Emilia, combined with the Master Agreement with the Japanese group “TOTO” (a pioneer in photo-catalytic technology with the HYDROTECT® brand), have led to the production of a new and exclusive generation of ceramic products for architecture.

To date, nobody else can offer such a complete range of high- performance products.

Casalgrande Padana’s offer includes:

Bios Self-Cleaning Ceramics®, a line of ceramic slabs for the installation of façade coatings capable of abating the pollutants in the air and decompose the dirt that deposits on their surfaces, which are therefore self-cleaning.

Bios Antibacterial Ceramics®, a line of ceramic slabs for floors and coating applications characterised by absolute anti-bacterial properties, which includes two types of products:

Bios Antibacterial HYDROTECT®, slabs that combine the anti- bacterial properties of noble metals with those of titanium dioxide, thus making the tiles capable of eliminating bacteria and bad smells even in conditions of complete absence of light.

This treatment is done on request on all the series of Casalgrande Padana’s catalogue; Bios Antibacterial GRANITOGRES®, lslabs that exploit the properties of an innovative anti-bacterial treatment with silver, capable of eliminating the main bacterial strains even in conditions of complete absence of light.

This treatment is applied to the mass of the tiles and is wear-resistant, so it is perfect for high-traffic conditions. The treatment is done on request, exclusively on the Granitogres line products.

The many international recognitions of Casalgrande Padana include the selection for ADI Design Index 2010; AIT Innovation Award 2010 “Architecture and Building”; AIT Innovation Award 2010 “Architecture and Flooring”; Produkt des Jahres 2011 (ranked 3rd) Fliesen Platten Leserwahl; Iconic Awards 2013.

Tactile® System

To meet the autonomy and safety requirements of visually impaired and elderly people and guide them along their paths both outdoor and in public or confined indoor spaces, Casalgrande Padana developed the Tactile® System (patent no. 00237769), a special kind of fine Granitogres porcelain stoneware tiles on which a special signalling language has been imprinted.

The elements of the modular floor are categorised based on simple-to-understand information codes that are linked to specific 3D and colour codes that mark stop lines, steps, crossings and deviations. Among the many international recognitions: the first prize of the “Soliditas Social Award 2006” and the “Good Design Award 2009”.

solutions for architecture

“our skills to serve your ideas”

Casalgrande Padana has been identified as the ideal partner by thousands of designers and clients worldwide thanks to the uniqueness of our products, to the expertise gained in over 50 years of activity in all sorts of constructions and architectures of all scales, types and final uses, to the capacity of offering a competent consulting service through Padana Engineering - a company specialising in the supply of support services for each step of the work, from the selection of materials to project development, tile laying and final testing. The culture of production and the culture of design have always been our cornerstones along a path of strong commitment to provide premium proposals, from the promotion of architecture projects to design and culture, publishing, art and support to important restoration work.

Grand Prix

International architecture competition

At its tenth edition this year, Grand Prix is an international architecture competition conceived and promoted in 1990 by Casalgrande Padana with the purpose of selecting and awarding the most significant projects that used porcelain stoneware materials of its own production. Through this cultural initiative, the company, which has always been particularly interested and focused on novelties and innovative ideas regarding the international architecture scenario, has promoted an event where ceramic shows all its strength, flexibility and eclecticism in various fields of the building industry - an event where tiles are not one of the many aspects, but the absolute protagonists of a project.

Creative Book and Casabella

Casalgrande Padana has consolidated its privileged relationship with designers by promoting a number of actions in support of the Grand Prix event, where it took care of a well-focused and efficient communication through meetings, conferences and publications. One of the most significant actions, in this regard, has been the cooperation with the international architecture magazine “Casabella”, which proactively works with Casalgrande Padana at developing the Grand Prix project. Starting from 2001, Casabella and Casalgrande Padana have collaborated at the production of the Creative Book, a professional updating tool that is attached to the magazine to disseminate the results of each Grand Prix edition.

Cooperate for innovation

During the course of its long business activity, Casalgrande Padana has started many cooperation relationships with important authors of the world of architecture and design, in order to develop very peculiar lines of research that have led to the construction of important works, as well as to the creation of innovative types of ceramic slabs and products. Among the most recent projects, we may mention those conducted with Kengo Kuma, the author of the spectacular architecture installation called “Casalgrande Ceramic Cloud” and the restoration of the museum-house “Old House”; the façade systems for the City Life Residences, the Pinnacle installation, the Vanke pavilion for Expo 2015 and a series of new tiles, designed by Daniel Libeskind; and again, the special polychromatic pieces for the outer surfaces of the MAST (Manifattura di Arte, Sperimentazione e Tecnologia) nursery in Bologna, a work by Studio Labics, where Bios Antibacterial GRANITOGRES® materials have also been used for tiling of the kitchen; the new ceramic slab series and 3D elements developed with the 5+1AA architecture agents Alfonso Femia, Gianluca Peluffo.

A pole for creativity

In order to give a tangible support to the partnerships with all the people who have a role in translating creativity into built architecture, Casalgrande Padana, based on a project of “Studio Cerri Associati Engineering”, developed the Creative Centre, a sustainable space open to the professionals of the sector, dedicated to design and training.

The Centre has been conceived as a place where a direct contact is established with the factory to spur interactions between innovation and creativity by combining exhibitions, communication, technical information and laboratory activities in the fields of architecture, design and manufacturing.

MORE ABOUT CASALGRANDE PADANA

Collections by Casalgrande Padana

Casalgrande Padana families

Casalgrande Padana products

Catalogues by Casalgrande Padana

-

2024

english, deutsch, italiano, français

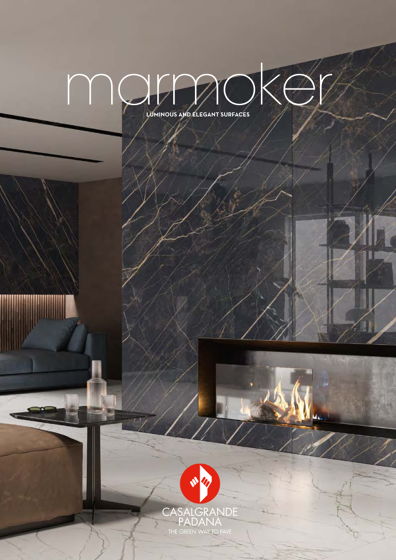

Marmoker

Casalgrande Padana

88 pages

-

2024

english, deutsch, italiano, français

Onici

Casalgrande Padana

44 pages

-

2024

english, deutsch, italiano, français

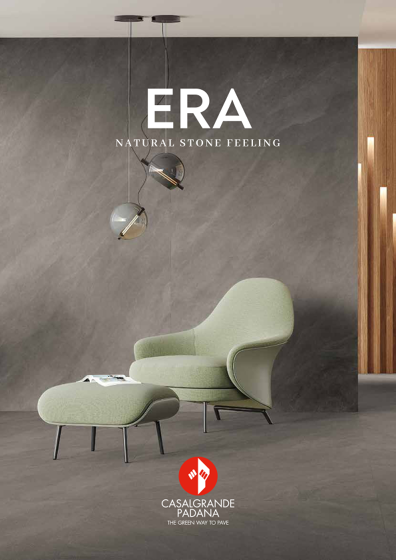

Era

Casalgrande Padana

56 pages

-

2024

english, deutsch, italiano, français

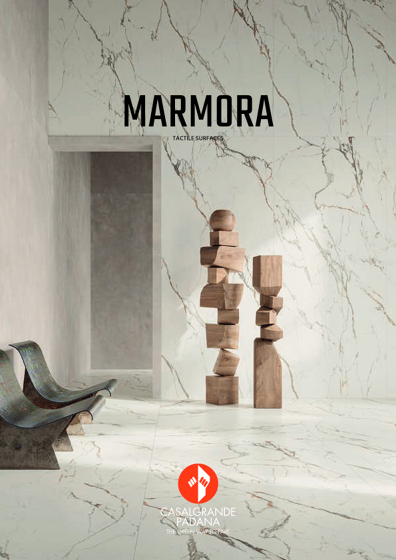

Marmora

Casalgrande Padana

52 pages

-

2024

english, deutsch, italiano, français

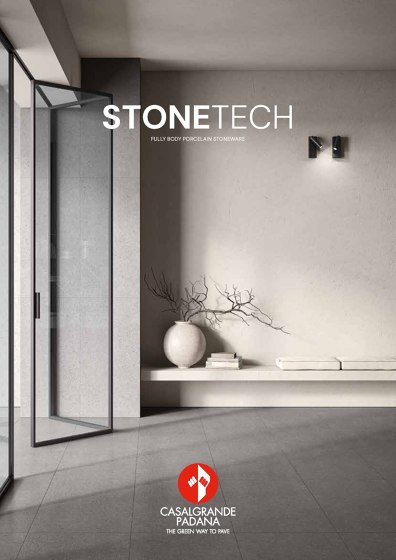

Stonetech

Casalgrande Padana

48 pages

-

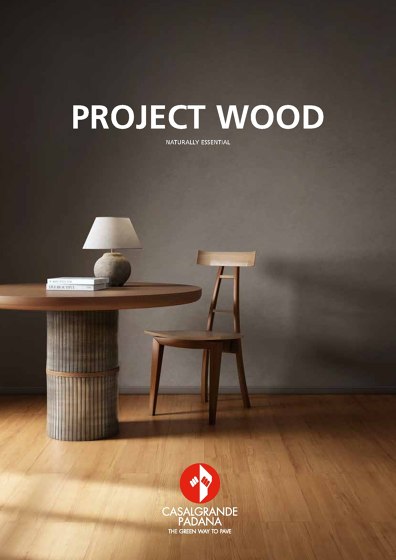

2024

english, deutsch, italiano, français

Project Wood

Casalgrande Padana

44 pages

-

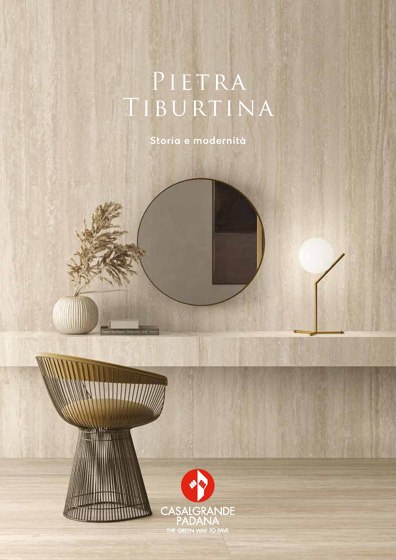

2024

english, deutsch, italiano, français

Pietra Tiburtina

Casalgrande Padana

60 pages

-

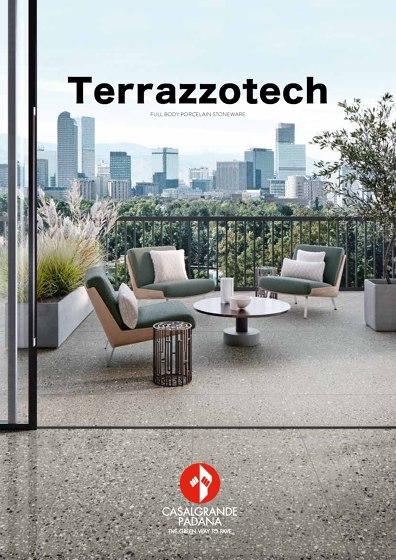

2023

english, deutsch, italiano, français

Terrazzotech

Casalgrande Padana

48 pages

-

2023

english, deutsch, italiano, français

Supreme

Casalgrande Padana

52 pages

- …

Casalgrande Padana projects

Casalgrande Padana articles

Casalgrande Padana news

Casalgrande Padana fairs

Casalgrande Padana videos

-

R - Evolution

Casalgrande Padana

2020-05-02

-

CP Kontinua 2019

Casalgrande Padana

2020-02-17

-

Casalgrande Padana 2019

Casalgrande Padana

2019-11-22

-

Bios Self-Cleaning - ITA

Casalgrande Padana

2017-10-03

-

Bios Self Cleaning ENG

Casalgrande Padana

2017-10-25

- …