About FibandCo

MORE ABOUT FIBANDCO

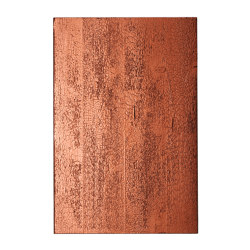

FIBandCO was born in the French Caribbean out of the observation that the banana fiber, one of the most abundant resources of fiber could offer an alternative to wood: every year, we lose more than 13 Ha of forest while 10 Ha of banana plantation are renewable all year long. We developed a technology to transform the banana steam that is cut after each fruit harvest all year long, into a responsible and sustainable natural veneer: Green Blade®. No water nor glue or bleaching process is used to produce Green Blade® in our factory located in the core of the banana farms region in Martinique. We work directly with banana farmers within a short and inclusive supply chain and we generate parts of our electricity with solar panels.

FIBandCO was born in the French Caribbean out of the observation that the banana fiber, one of the most abundant resources of fiber could offer an alternative to wood: every year, we lose more than 13 Ha of forest while 10 Ha of banana plantation are renewable all year long. We developed a technology to transform the banana steam that is cut after each fruit harvest all year long, into a responsible and sustainable natural veneer: Green Blade®. No water nor glue or bleaching process is used to produce Green Blade® in our factory located in the core of the banana farms region in Martinique. We work directly with banana farmers within a short and inclusive supply chain and we generate parts of our electricity with solar panels.

MORE ABOUT FIBANDCO