MANUFACTURING CENTRE Every piece of furniture in the Röthlisberger Kollektion seeks to be the perfect translation of a new concept. Frequently, new manufacturing methods have to be found and implemented to achieve this. Naturally, such a level of innovative spirit also requires space. In Gümligen, a well-designed development and production area meets this need. Cutting-edge technology complements first-class craftsmanship. Efficient production processes have been further optimised with the opening of a centre extension in 2012. Like the 2002 new building, the cuboid timber construction with 1800 m2 of floor space was also designed by architectural firm ARB, Bern, and Trix and Robert Haussmann. Our furniture is made and finished by hand here in accordance with best practice. However, much happens before an item of furniture leaves the manufacturing centre: intensive consultation with the designer, a great deal of trust and a continual exploration of what can be done, and how. It’s a process that also needs passion and expertise. The designer and all who work at Röthlisberger need to be driven by one motive: creating furniture that inspires from a visual, haptic and functional standpoint. MATERIAL KNOWLEDGE Just as a leading chef will only work with the finest ingredients, a piece of furniture in the Röthlisberger Kollektion will only be crafted from the very best materials. Over 80 years of carpentry tradition guarantee careful selection and professional workmanship. Our timber store is stocked primarily with indigenous woods from rigorously selected suppliers: ash, oak, walnut, pear and many more. Working with this organic raw material requires a lot of experience. Where necessary, we will treat timber in our own drying kiln until it exhibits the best possible stability. This enables us to guarantee the quality of our furniture for many years. The appeal and uniqueness of a piece of furniture is often also a question of choosing the right veneer. That’s why our veneer warehouse is stocked with only the finest woods. We hold 40 types in stock at any one time. And their diversity of patterns and figurings opens a wide spectrum of possibilities. Modern CNC machines are used for precision processing: namely sawing, countersinking and sanding. At the Röthlisberger Kollektion we take the proverbial ‘finishing touch’ in a very literal sense: it’s the finest carpentry craftsmanship, applied with a passion for perfection. VISION AND TECHNICAL FEASIBILITY. The translation of a complex concept into a three-dimensional object is a core ability of Röthlisberger Kollektion. Often, the idea put forward by the designer will be based on a selection of materials, an interplay of colours or a model. Intensive consultation – a to-and-fro between vision and technical feasibility – then begins. Accepting responsibility for what is possible under our roof is Peter Röthlisberger. An idea will be refined and revised in a process of close collaboration: the creation of sketches, deliberations about shapes and dimensions, discussions about and trials of materials, colours, structures and surface feels. Sometimes an entirely new approach emerges. And often, it is a struggle to reach detailed solutions. But it is always one thing: a process that demands much trust, but also imagination, experience and intuition. It is how vision gives rise to a conceptual design. And with it, the basis for the next production steps. Manufacturing processes are trialled, working drawings, models and prototypes produced. Often, they are rejected and improved. Until the concept is able to be realised optimally and, with it, become part of the Röthlisberger Kollektion.

Read moreCollections

See all collectionsFeatured Products

See all productsCatalogs

See all catalogsRead more about Röthlisberger Kollektion

See all storiesAbout Röthlisberger Kollektion

MANUFACTURING CENTRE

Every piece of furniture in the Röthlisberger Kollektion seeks to be the perfect translation of a new concept. Frequently, new manufacturing methods have to be found and implemented to achieve this. Naturally, such a level of innovative spirit also requires space. In Gümligen, a well-designed development and production area meets this need. Cutting-edge technology complements first-class craftsmanship. Efficient production processes have been further optimised with the opening of a centre extension in 2012. Like the 2002 new building, the cuboid timber construction with 1800 m2 of floor space was also designed by architectural firm ARB, Bern, and Trix and Robert Haussmann.

Our furniture is made and finished by hand here in accordance with best practice. However, much happens before an item of furniture leaves the manufacturing centre: intensive consultation with the designer, a great deal of trust and a continual exploration of what can be done, and how. It’s a process that also needs passion and expertise. The designer and all who work at Röthlisberger need to be driven by one motive: creating furniture that inspires from a visual, haptic and functional standpoint.

MATERIAL KNOWLEDGE

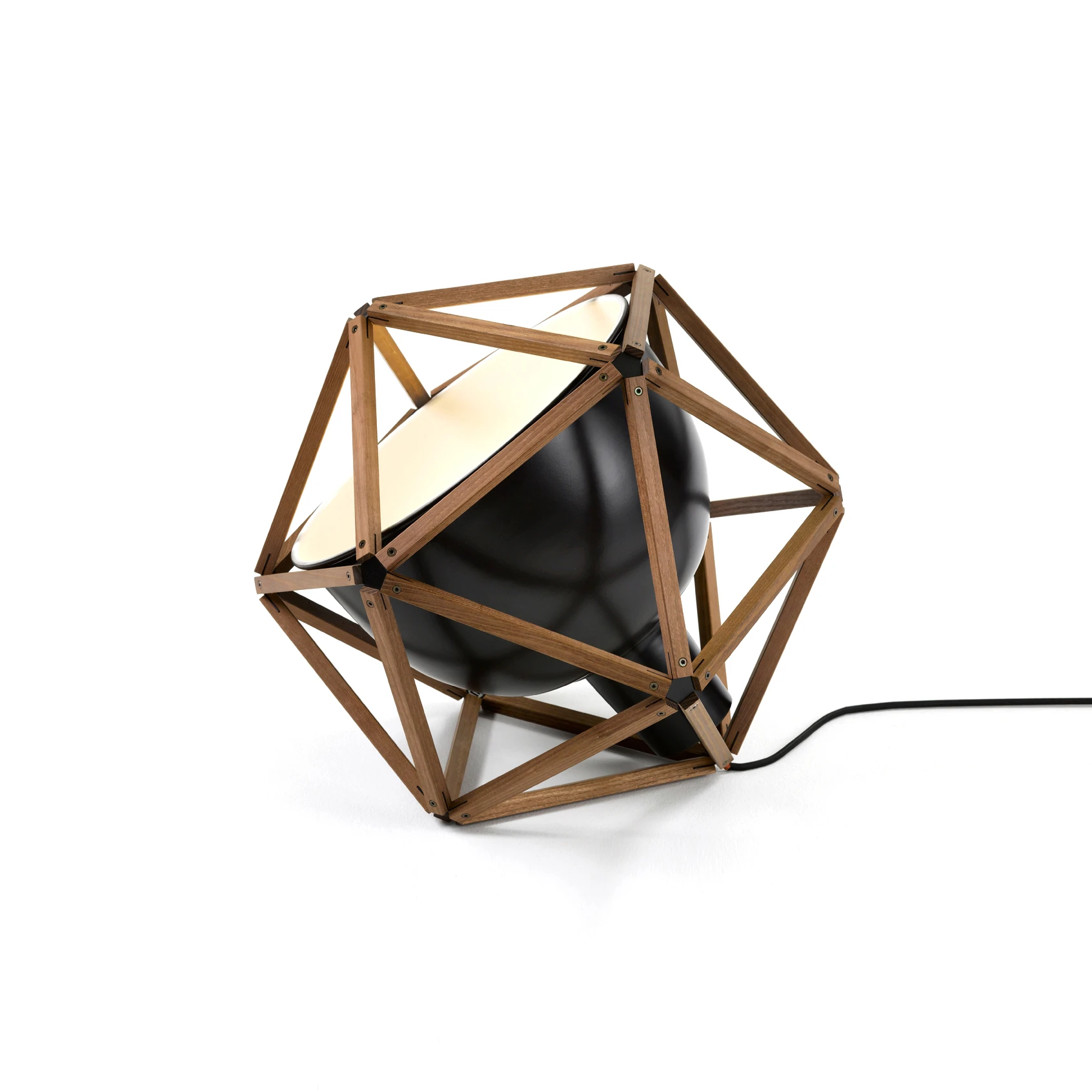

Just as a leading chef will only work with the finest ingredients, a piece of furniture in the Röthlisberger Kollektion will only be crafted from the very best materials. Over 80 years of carpentry tradition guarantee careful selection and professional workmanship. Our timber store is stocked primarily with indigenous woods from rigorously selected suppliers: ash, oak, walnut, pear and many more. Working with this organic raw material requires a lot of experience. Where necessary, we will treat timber in our own drying kiln until it exhibits the best possible stability. This enables us to guarantee the quality of our furniture for many years.

The appeal and uniqueness of a piece of furniture is often also a question of choosing the right veneer. That’s why our veneer warehouse is stocked with only the finest woods. We hold 40 types in stock at any one time. And their diversity of patterns and figurings opens a wide spectrum of possibilities. Modern CNC machines are used for precision processing: namely sawing, countersinking and sanding. At the Röthlisberger Kollektion we take the proverbial ‘finishing touch’ in a very literal sense: it’s the finest carpentry craftsmanship, applied with a passion for perfection.

VISION AND TECHNICAL FEASIBILITY.

The translation of a complex concept into a three-dimensional object is a core ability of Röthlisberger Kollektion. Often, the idea put forward by the designer will be based on a selection of materials, an interplay of colours or a model. Intensive consultation – a to-and-fro between vision and technical feasibility – then begins. Accepting responsibility for what is possible under our roof is Peter Röthlisberger. An idea will be refined and revised in a process of close collaboration: the creation of sketches, deliberations about shapes and dimensions, discussions about and trials of materials, colours, structures and surface feels. Sometimes an entirely new approach emerges.

And often, it is a struggle to reach detailed solutions. But it is always one thing: a process that demands much trust, but also imagination, experience and intuition.

It is how vision gives rise to a conceptual design. And with it, the basis for the next production steps. Manufacturing processes are trialled, working drawings, models and prototypes produced. Often, they are rejected and improved. Until the concept is able to be realised optimally and, with it, become part of the Röthlisberger Kollektion.