Cutting

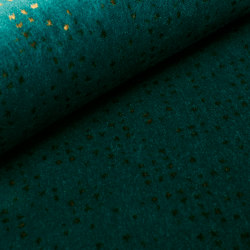

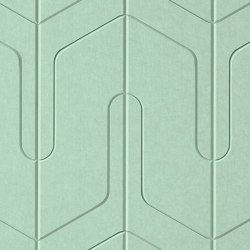

Surface finishings from BOXMARK Leather GmbH & Co KG

Product description

One of BOXMARK’s strengths is to precisely process and flexibly adjust cutting orders. To meet even the most short-dated customer change requests, BOXMARK uses state-of-the-art hydrocut plants. That’s why BOXMARK is able to digitally process construction sheets without long-term tool manufacturing beforehand. Depending on the task or design sheets of our customers, leather can be processed to leather parts on rolling or beam cutting presses with custom made die-cutting knives.

The classification of all the surface characteristics is done digitally using the most sophisticated state-of-the-art technology.

The virtual cut forms are positioned on the scanned leather skin with the highest possible efficiency.

A 0.1 mm water jet and a pressure of 2.000 bar create accurately cut leather parts.

As an alternative to the water jet, swivel arm cutting presses, bridge cutting presses and roller cutting machines are also available for custom designed orders.

The classification of all the surface characteristics is done digitally using the most sophisticated state-of-the-art technology.

The virtual cut forms are positioned on the scanned leather skin with the highest possible efficiency.

A 0.1 mm water jet and a pressure of 2.000 bar create accurately cut leather parts.

As an alternative to the water jet, swivel arm cutting presses, bridge cutting presses and roller cutting machines are also available for custom designed orders.

Manufacturer

BOXMARK Leather GmbH & Co KG

Family

Services

Architonic ID

1360104

Similar products

This product has been archived. Product information may no longer be up to date.

Similar products

Where to buy this product

Where to buy this product