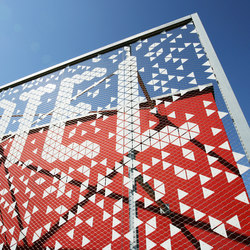

CELLON® design | Shading Elements

Facade systems from Bruag

Product description

Our CELLON® panel is a Compact High-Pressure Laminate Panel (HPL) consisting of 70% cellulose

sheets and 30% phenolic resin. The weather-resistant material is ideally suited for external applications. The raw panels are cut project-specifically using laser technology. The panels are thus pre-cut to to the exact dimensions (incl. boreholes) and with the chosen perforation. After the cutting process the panels are coated. Depending on the perforation and the distance between the fixing points, panels with 8 mm or 10 mm thickness are used.

Raw Material Formats (Panels are always cut exactly to size of project request):

1.20m x 2.40m

1.28m x 3.00m

1.50m x 3.60m (The dimensions of the panel are 1500 x 3600 mm. However, due to machine coating, façade panels can only be offered up to a width of 1300 mm.)

1.80m x 3.60m (The dimensions of the panel are 1800 x 3600 mm. However, due to machine coating, façade panels can only be offered up to a width of 1300 mm.)

Colour Options: NCS S Edition 2, RAL or 14 possible Bruag ALU shades (other colours as IGP, DB etc on request)

The Advantages at a Glance:

• the unlimited selection of perforation patterns and colours provide a large variety of design

• options, this way the degree of transparency can be selected freely

• project-specific factory-made cutting with laser technology based on CAD files or parts lists

• (delivered ready for installation including all cut-outs and boreholes)

• a selection of over 100 Bruag perforations patterns is available

• custom patterns according your CAD drawing at no additional costs

• perforation pattern can run smoothly across multiple panels

• coated in over 3’000 different colours (according to NCS S, RAL, Bruag Alu or IGP) or with

• wooden or stone décor

• moisture- and weather-resistant, frost and termite proof, UV-resistant

• colours have excellent light fastness, Light fastness 7.5-8 (from 8), weather fastness 4.5-5 (from 5)

• lightweight (7-9kg/m2 for CELLON® 8 mm with approx. 30% open area) with very high break resistance

• extremely low shrinkage and swelling behaviour

• ready-to-install product including drill holes and cut-outs

• post-processing on site possible (holes and cut-outs)

• billing of net size only (no wastage)

• FSC certified

Fire Properties: RF2, BKZ 5.3, B-s1-d0 according EN 13501-1

sheets and 30% phenolic resin. The weather-resistant material is ideally suited for external applications. The raw panels are cut project-specifically using laser technology. The panels are thus pre-cut to to the exact dimensions (incl. boreholes) and with the chosen perforation. After the cutting process the panels are coated. Depending on the perforation and the distance between the fixing points, panels with 8 mm or 10 mm thickness are used.

Raw Material Formats (Panels are always cut exactly to size of project request):

1.20m x 2.40m

1.28m x 3.00m

1.50m x 3.60m (The dimensions of the panel are 1500 x 3600 mm. However, due to machine coating, façade panels can only be offered up to a width of 1300 mm.)

1.80m x 3.60m (The dimensions of the panel are 1800 x 3600 mm. However, due to machine coating, façade panels can only be offered up to a width of 1300 mm.)

Colour Options: NCS S Edition 2, RAL or 14 possible Bruag ALU shades (other colours as IGP, DB etc on request)

The Advantages at a Glance:

• the unlimited selection of perforation patterns and colours provide a large variety of design

• options, this way the degree of transparency can be selected freely

• project-specific factory-made cutting with laser technology based on CAD files or parts lists

• (delivered ready for installation including all cut-outs and boreholes)

• a selection of over 100 Bruag perforations patterns is available

• custom patterns according your CAD drawing at no additional costs

• perforation pattern can run smoothly across multiple panels

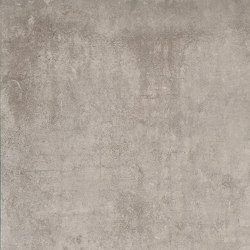

• coated in over 3’000 different colours (according to NCS S, RAL, Bruag Alu or IGP) or with

• wooden or stone décor

• moisture- and weather-resistant, frost and termite proof, UV-resistant

• colours have excellent light fastness, Light fastness 7.5-8 (from 8), weather fastness 4.5-5 (from 5)

• lightweight (7-9kg/m2 for CELLON® 8 mm with approx. 30% open area) with very high break resistance

• extremely low shrinkage and swelling behaviour

• ready-to-install product including drill holes and cut-outs

• post-processing on site possible (holes and cut-outs)

• billing of net size only (no wastage)

• FSC certified

Fire Properties: RF2, BKZ 5.3, B-s1-d0 according EN 13501-1

Concept

CELLON® design: for your unique flagship project

An individually perforated façade – an eye-catcher with sustainableeffect:

An exquisite character of your building. Be it a complete perforated or partially perforated façade for an interesting interplay of light and shadow or as an acoustic solution, CELLON® design panels are available in over 100 standard perforations or according to your own customer-made pattern in all RAL or NCS S colours.

An individually perforated façade – an eye-catcher with sustainableeffect:

An exquisite character of your building. Be it a complete perforated or partially perforated façade for an interesting interplay of light and shadow or as an acoustic solution, CELLON® design panels are available in over 100 standard perforations or according to your own customer-made pattern in all RAL or NCS S colours.

More about this product

Categorised in Facade - Facade systems - Panel systems - perforated - HPL High Pressure Laminate - Composite material - Building construction.

Part of the collection

SHADING AND SLIDING ELEMENTS.

Manufacturer

Bruag

Family

CELLON® design

Architonic ID

20269502

Similar products

Related Projects

This product has been archived. Product information may no longer be up to date.