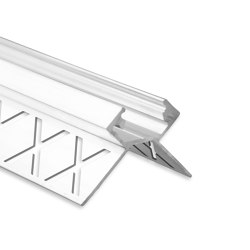

FP8 series | FP8 LED tile profile INNER CORNER 200 cm

Profiles from Galaxy Profiles

Product description

Homogeneous light with modular LED lighting solutions from GALAXY profiles

Intelligent product design and unique product compatibility are the basis for groundbreaking LED lighting concepts. LED profile systems from GALAXY profiles are modular LED lighting solutions. The individual system components are put together with little effort, simply and quickly using a click system, and are mounted in a substance-preserving manner. Designed for tile concepts!

This INNER CORNER FP8 LED TILE profile is available in the standard lengths of 200 cm and 250 cm, and is designed for LED flexbands with a maximum width of 14 mm. In the back cavity of the aluminium profile, the connecting cables are protected and securely laid. This profile system is filled in with tile adhesive on the lateral, large-area wings (20 mm wide) in vertical corners of a room and thus integrated into the tile concept. The LED profile covers (opal/satin - light transmission 65% - also available in 300 cm and 600 cm | transparent - light transmission 85%) are made of shatter-proof and flame-retardant polycarbonate (classification flammability UL94V-2 ), are flush-mounted and create homogeneous LED lighting conditions with high utilisation of the light output.

Easy and quick installation

The self-adhesive LED Stripe is inserted in the LED profile, glued and wired (rear-sided cable routing). After the profile cover has been clicked flush into the profile, the open ends and all joints are sealed with silicone. Then, tile adhesive is used to putty the LED profile with the building fabric and finally, it is connected to the LED lighting and control systems (LED transformer, LED sequencer, etc.).

Recommendation

For an excellent adhesion of the self-adhesive LED strips, we recommend the thorough cleaning and degreasing of the profile insides with a cleaner - see accessories.

Important information:

The use in wet cells or outdoors is possible only in sealed form. Special protection against moisture and water is provided by silicone, which is applied to the joints for sealing purposes. Absolute watertightness is achieved for the LED profile systems by casting with Wepuran casting resin on polyurethane resin-basis (PUR). When selecting the LED flex band, make sure that the protection class specified by the manufacturer (at least IP65) is maintained.

Order picking and standard custom-made product (OEM)

From a minimum purchase quantity onwards, the LED profiles and plastic covers from our standard range are made to order or produced custom-made according to customer-specific length specifications up to max. 6 m total length per LED profile system. On request, LED aluminium profiles by GALAXY profiles can be produced in all RAL colours (powder coating).

We gladly await your inquiries! Perfect Light Lines by GALAXY profiles

Intelligent product design and unique product compatibility are the basis for groundbreaking LED lighting concepts. LED profile systems from GALAXY profiles are modular LED lighting solutions. The individual system components are put together with little effort, simply and quickly using a click system, and are mounted in a substance-preserving manner. Designed for tile concepts!

This INNER CORNER FP8 LED TILE profile is available in the standard lengths of 200 cm and 250 cm, and is designed for LED flexbands with a maximum width of 14 mm. In the back cavity of the aluminium profile, the connecting cables are protected and securely laid. This profile system is filled in with tile adhesive on the lateral, large-area wings (20 mm wide) in vertical corners of a room and thus integrated into the tile concept. The LED profile covers (opal/satin - light transmission 65% - also available in 300 cm and 600 cm | transparent - light transmission 85%) are made of shatter-proof and flame-retardant polycarbonate (classification flammability UL94V-2 ), are flush-mounted and create homogeneous LED lighting conditions with high utilisation of the light output.

Easy and quick installation

The self-adhesive LED Stripe is inserted in the LED profile, glued and wired (rear-sided cable routing). After the profile cover has been clicked flush into the profile, the open ends and all joints are sealed with silicone. Then, tile adhesive is used to putty the LED profile with the building fabric and finally, it is connected to the LED lighting and control systems (LED transformer, LED sequencer, etc.).

Recommendation

For an excellent adhesion of the self-adhesive LED strips, we recommend the thorough cleaning and degreasing of the profile insides with a cleaner - see accessories.

Important information:

The use in wet cells or outdoors is possible only in sealed form. Special protection against moisture and water is provided by silicone, which is applied to the joints for sealing purposes. Absolute watertightness is achieved for the LED profile systems by casting with Wepuran casting resin on polyurethane resin-basis (PUR). When selecting the LED flex band, make sure that the protection class specified by the manufacturer (at least IP65) is maintained.

Order picking and standard custom-made product (OEM)

From a minimum purchase quantity onwards, the LED profiles and plastic covers from our standard range are made to order or produced custom-made according to customer-specific length specifications up to max. 6 m total length per LED profile system. On request, LED aluminium profiles by GALAXY profiles can be produced in all RAL colours (powder coating).

We gladly await your inquiries! Perfect Light Lines by GALAXY profiles

More about this product

Part of the collection

LED Tile profiles.

Manufacturer

Galaxy Profiles

Family

FP8 series

Architonic ID

20084955

Order number

8102030

Similar products

This product has been archived. Product information may no longer be up to date.