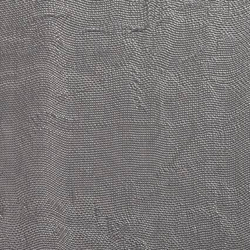

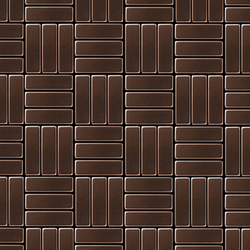

H26/180 Wood matt Walnut Maser

Composite panels from Homapal

Product description

Concept

Size: 2440 x 1220 mm

HOMAPAL HOLZ is a laminate (HPL) with a surface of ready-to-use real wood. By using reconstituted veneers as well by the final coating we can assure a nearly constant image of the veneer.

For the production of reconstituted veneers, peeled veneers from poplar-, koto- and ayous wood are partly dyed, rejoined together in layers and pressed to a block from which the reconstituted veneers are sliced. By putting together different peeled veneers and using special pressings the most popular, even exotic species of timber can be reproduced. Valuable resources are saved this way, without having to give up special and extravagant decors. We press these reconstituted veneers in the wellknown production process to laminates. The surface is finally lacquered or melamine coated, inspected and covered with a protective film.

HOMAPAL-HOLZ surfaces

- Surfaces with acrylic lacquer

- Surfaces with melamine coating (matt)

- Surfaces with melamine coating (structured)

NATURAL COMPONENTS:

Although it is a reconstituted veneer small variations of the grain resp. of the colour are unavoidable and show only the natural characteristics of wood.

HYGROSCOPICITY:

The material tends to adapt the moisture of the wood to the environmental moisture, thus wood has a small dimensional stability (expansion resp. shrinkage)

LIGHT FASTNESS:

Influenced by Strong UV-light all different types of wood – even reconstituted woods - change their colour. Therefore, we recommend using HOMAPAL HOLZ for interior applications that are not exposed to sunlight directly.

PROTECTIVE FILM:

HOMAPAL sheets are covered with a protective foil. It is recommended to leave this foil on the surface of the laminates during processing. Nevertheless, colour, colour uniformity and other quality checks of the sheets must be carried out beforehand.

Important:

The surface which is protected with a removable foil should not be exposed to light for long periods of time. This could cause problems in removing the protective foil. (Use a cover sheet)! The protective foil is not diffusion tight towards liquids.

PROCESSING:

HOMAPAL HOLZ products can be sawn, drilled, milled etc. like all standard high pressure laminates. The sheets can be bonded to standard base materials with conventional glues or adhesives.

CARE/CLEANING:

To clean the surface use a soft non-pilling cloth and a mild cleaning agent that must not contain any abrasive substances. Do not use any solvent.

APPLICATION:

HOMAPAL HOLZ laminates are recommended for interior vertical applications in which the products are hardly exposed to harmful environmental conditions such as strong UV light or extreme changes in temperature.

BALANCING MATERIAL:

Stresses always occur between two different types of material bonded together. Consequently, a base material should be surfaced on each side with materials which are subject to the same dimensional changes resulting from variations in temperature and influence of humidity. This is particularly important if the finished sheet is to be self-supporting and not directly retained by a rigid structure. It is necessary to condition all materials in the same climatic conditions for at least 48 hours.

HOMAPAL HOLZ is a laminate (HPL) with a surface of ready-to-use real wood. By using reconstituted veneers as well by the final coating we can assure a nearly constant image of the veneer.

For the production of reconstituted veneers, peeled veneers from poplar-, koto- and ayous wood are partly dyed, rejoined together in layers and pressed to a block from which the reconstituted veneers are sliced. By putting together different peeled veneers and using special pressings the most popular, even exotic species of timber can be reproduced. Valuable resources are saved this way, without having to give up special and extravagant decors. We press these reconstituted veneers in the wellknown production process to laminates. The surface is finally lacquered or melamine coated, inspected and covered with a protective film.

HOMAPAL-HOLZ surfaces

- Surfaces with acrylic lacquer

- Surfaces with melamine coating (matt)

- Surfaces with melamine coating (structured)

NATURAL COMPONENTS:

Although it is a reconstituted veneer small variations of the grain resp. of the colour are unavoidable and show only the natural characteristics of wood.

HYGROSCOPICITY:

The material tends to adapt the moisture of the wood to the environmental moisture, thus wood has a small dimensional stability (expansion resp. shrinkage)

LIGHT FASTNESS:

Influenced by Strong UV-light all different types of wood – even reconstituted woods - change their colour. Therefore, we recommend using HOMAPAL HOLZ for interior applications that are not exposed to sunlight directly.

PROTECTIVE FILM:

HOMAPAL sheets are covered with a protective foil. It is recommended to leave this foil on the surface of the laminates during processing. Nevertheless, colour, colour uniformity and other quality checks of the sheets must be carried out beforehand.

Important:

The surface which is protected with a removable foil should not be exposed to light for long periods of time. This could cause problems in removing the protective foil. (Use a cover sheet)! The protective foil is not diffusion tight towards liquids.

PROCESSING:

HOMAPAL HOLZ products can be sawn, drilled, milled etc. like all standard high pressure laminates. The sheets can be bonded to standard base materials with conventional glues or adhesives.

CARE/CLEANING:

To clean the surface use a soft non-pilling cloth and a mild cleaning agent that must not contain any abrasive substances. Do not use any solvent.

APPLICATION:

HOMAPAL HOLZ laminates are recommended for interior vertical applications in which the products are hardly exposed to harmful environmental conditions such as strong UV light or extreme changes in temperature.

BALANCING MATERIAL:

Stresses always occur between two different types of material bonded together. Consequently, a base material should be surfaced on each side with materials which are subject to the same dimensional changes resulting from variations in temperature and influence of humidity. This is particularly important if the finished sheet is to be self-supporting and not directly retained by a rigid structure. It is necessary to condition all materials in the same climatic conditions for at least 48 hours.

More about this product

Categorised in Laminates / Composites - Wall coverings - Composite panels - Wall panels - Effect wood - Compact laminate - HPL High Pressure Laminate - Composite material.

Manufacturer

Homapal

Family

H26/180 Wood matt Walnut Maser

Architonic ID

1074920

Similar products

This product has been archived. Product information may no longer be up to date.