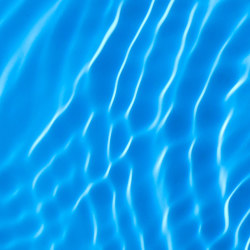

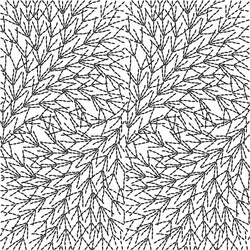

Art Diffusion® panel Bio6F

Wood panels from Interlam

Product description

Concept

Pattern Depth: 0.40"

Min. Rec. panel thickness: 0.75"

Pattern Repeat Type: repeating

The Art Diffusion product offers the customer an extremely broad variety of patterns, materials, finishes and installation choices. In order to translate a customer requirement into an accurate product specification, it is important to understand all of the product options and terms used to describe these options. The elements line is available in the 4x8’s only and in 1 pattern direction as shown. Product specification terms and options are discussed below along with helpful illustrations.

It is important to first select a core material based on specific project needs, such as contribution towards "Leed" credits, FSC Certified fibers with chain of custody, Class A fire rating, radius applications, interior or exterior applications, formaldehyde emissions or moisture resistance. Core materials are available to fit most special needs such as radius or serpentine installations, opaque wall dividers or exterior applications. Not all core materials are available in all sizes and patterns. Consult the material matrix to determine available thickness and sheet size for each individual core. Lead times will be increased if a non-standard sheet size or thickness is required for any given job.

Core materials options:

Arreis – SDF

Arreis© Sustainable Design Fiberboard (SDF)* is the most affordable sustainable Medium Density Fiberboard offered by SierraPine. Developed specifically by SierraPine, using a patent-pending manufacturing process, to drive down the cost of environmental stewardship and simultaneously deliver the high performance MDF you expect. Manufacturers, designers and specifiers now have a new affordable MDF supporting environmental design:

- Formaldehyde free adhesive system

- Physical properties similar to, or better than standard MDF

- 100% recycled wood fiber

- FSC mixed credit certified - available option

- LEED® credit support: M&R 4.1, 4.2, 5.1, 5.2, 7 & EQ 4.4

- Third party certifi cation - SCS & EPP

- CHPS compliant - California section 01350 approved

- Maximum 1 ¼” thickness

*About Sustainable Design Fiberboard

SDF products include a broad range of high quality MDF products manufactured by SierraPine to meet or exceed the most stringent global emission standards.

Medite – FR

SierraPine flame retardant Medite® FR is made with a formaldehyde free adhesive system and is designed for critical applications where Class 1 flame retardant material is required. Medite FR has a low flame spread and smoke development as well as extremely low VOC emissions. During the manufacturing process, the flame retardant additive is blended with the fiber throughout the panel. This process delivers superior performance versus topical flame retardant applications. In addition, Medite FR can be machined, cut, sanded, and grooved without compromising the flame retardance.

Guardian Certified to U.S. & Canadian Class 1 standards:

- Flame Spread rating - 20

- Smoke Development rating - 100

- 100% recycled wood fiber

- FSC mixed credit certified – AVAILABLE AS AN OPTION WITH AN UPCHARGE & CHAIN OF CUSTODY

- LEED® credit support: M&R 4.1, 4.2, 5.1, 5.2, 7 and EQ 4.4

- Third party certifi cation - SCS, EPP, Guardian

- CHPS compliant - California section 01350 approve

- Maximum 1 ¼” thickness

Celtec® Expanded Rigid Foam PVC/ Radius Applications

Celtec Displayboard is a foamed polyvinyl chloride (PVC) sheet whose extraordinary combination of features makes it ideal for signage, exhibits, store displays, POP, Kiosks, screen printing and more. The surface is a smooth matte finish that makes it ideal to paint or laminate to secondary substrates. Celtec also has good screw and staple retention which makes it ideal for stage prop design, cabinetry and other wood replacement projects.

Sheets are tough, high-strength and lightweight, and can be ordered in a wide range of sizes, thicknesses and colors. Celtec sheets are free of lead, cadmium, barium and zinc… and have passed all three UL 1975 requirements. Celtec is recommended for industrial and commercial signage. It readily accepts virtually any form of graphic overlay (print, paint and photo mounting). Celtec is also easy to cut and shape, making it a strong choice for three-dimensional exhibits, displays and stage sets.

- Lightweight Celtec is easy to handle, easy to work with.

- Low Flammability Celtec meets UL94 5V, UL 1975 and has a fl ame spread of 20 according to ASTM E84.

- Water resistant Celtec has a closed cell structure and has extremely low water absorption values.

- Surface Celtec’s smooth matte surface is ideal for graphics, printing and laminating.

- Weatherability Celtec is more color-fast than other foam PVC products.

- Strength Celtec has an excellent strength to weight ratio as shown in the screw and staple pull test data.

- Thermal Conductivity Celtec has excellent insulating characteristics.

- Safety Celtec contains no lead, cadmium or zinc.

- Maximum 30mm thickness

Extira

Extira is a revolutionary new-to-the-world material that is unique in three ways:

Extira is a panel product that resists moisture, rot and termites and offers excellent performance in exterior environments.

Extira can be used in any non-structural paint-grade EXTERIOR application. It also works well for high moisture interior environments.

Extira has a 5-year limited warranty, unprecedented in its product category.

Valchromat - Engineered colored wood

Wood fiber panel colored throughout. Innovative because it was the first product of its kind in the market and unique for its exclusive physical properties that set it aside and make Valchromat the star product of our company.

Thicknesses: 8mm, 19mm, other thicknesses available as special order.

Flakeboard

Premier® Plus HDF – Our standard HDF

The series refined fibers and elevated properties of our Plus product allow for a superior surface for critical applications such as thin paper laminates and thermally fused melamine, while its increased internal bond provides excellent results for the most intricate machining projects.

Premier® Fire Rated MDF

This fire-retardant panel is manufactured on our Premier Plus platform using a chemical system to achieve a fire-rated panel that is classified by Underwriters Laboratories for surface burning characteristics. Premier® MDF is ideal for commercial and institutional cabinets, paneling, case work and moulding trim when required by fire safety codes and architectural specifications.

Maximum thickness of 1 ½”.

Premier® FR has a Class A fire rating; Flame spread 15; Smoke developed 95

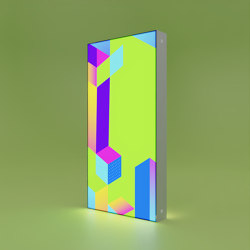

Cyro ACRYLITE® Acrylic

- Clarity - unsurpassed; up to 92% light transmission

- UV Resistance - usually withstands years of sunlight without yellowing

- Surface Hardness - high

- Colorability - easily made different colors, translucency, or opacity levels

- USP Class VI - most ACRYLITE gradesFD

ACRYLITE® acrylics by CYRO have up to the theoretical max. light transmission1, high surface hardness, and good UV resistance. All grades of ACRYLITE compounds are available in clear and a wide spectrum of transparent, translucent and opaque colors.

Panel Size

The standard panel size is 48” x 96” ( 4 x 8 ). Custom panels can be produced up to 60” wide and up to 120” long. Not all core materials are available in the larger sizes.

Panel Thickness

Panel thickness refers to the thickness of the raw stock prior to machining. After machining, the thickest area of the panel will be slightly less than this nominal panel thickness. Panel stock thickness ranges from 1/2” to 1 ½” . Many factors will determine the final panel thickness such as Pattern choice, installation methods and material availability.

Pattern Depth

The pattern depth refers to the deepest cut that is made in the raw stock in order to produce the pattern. Most patterns are offered in only one depth, however a few have multiple depth options as indicated on the specific pattern page.

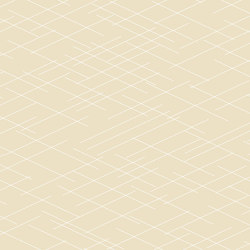

Pattern Direction- EXTREMELY CRITICAL!!!

Most patterns can be produced in either vertical or horizontal orientation. Referring to the illustration at right, a pattern is said to be horizontal if the tool marks run generally the short direction and vertical if the tool marks run generally in the long direction. Please note that the vertical and horizontal designations have nothing to do with the installed orientation. For multiple panel layouts or panels that are approximately square, orientation should be indicated in an attached layout sketch. The direction of some patterns is not always obvious, so please refer to individual pattern photos in the catalogue to determine the preferred orientation.

Min. Rec. panel thickness: 0.75"

Pattern Repeat Type: repeating

The Art Diffusion product offers the customer an extremely broad variety of patterns, materials, finishes and installation choices. In order to translate a customer requirement into an accurate product specification, it is important to understand all of the product options and terms used to describe these options. The elements line is available in the 4x8’s only and in 1 pattern direction as shown. Product specification terms and options are discussed below along with helpful illustrations.

It is important to first select a core material based on specific project needs, such as contribution towards "Leed" credits, FSC Certified fibers with chain of custody, Class A fire rating, radius applications, interior or exterior applications, formaldehyde emissions or moisture resistance. Core materials are available to fit most special needs such as radius or serpentine installations, opaque wall dividers or exterior applications. Not all core materials are available in all sizes and patterns. Consult the material matrix to determine available thickness and sheet size for each individual core. Lead times will be increased if a non-standard sheet size or thickness is required for any given job.

Core materials options:

Arreis – SDF

Arreis© Sustainable Design Fiberboard (SDF)* is the most affordable sustainable Medium Density Fiberboard offered by SierraPine. Developed specifically by SierraPine, using a patent-pending manufacturing process, to drive down the cost of environmental stewardship and simultaneously deliver the high performance MDF you expect. Manufacturers, designers and specifiers now have a new affordable MDF supporting environmental design:

- Formaldehyde free adhesive system

- Physical properties similar to, or better than standard MDF

- 100% recycled wood fiber

- FSC mixed credit certified - available option

- LEED® credit support: M&R 4.1, 4.2, 5.1, 5.2, 7 & EQ 4.4

- Third party certifi cation - SCS & EPP

- CHPS compliant - California section 01350 approved

- Maximum 1 ¼” thickness

*About Sustainable Design Fiberboard

SDF products include a broad range of high quality MDF products manufactured by SierraPine to meet or exceed the most stringent global emission standards.

Medite – FR

SierraPine flame retardant Medite® FR is made with a formaldehyde free adhesive system and is designed for critical applications where Class 1 flame retardant material is required. Medite FR has a low flame spread and smoke development as well as extremely low VOC emissions. During the manufacturing process, the flame retardant additive is blended with the fiber throughout the panel. This process delivers superior performance versus topical flame retardant applications. In addition, Medite FR can be machined, cut, sanded, and grooved without compromising the flame retardance.

Guardian Certified to U.S. & Canadian Class 1 standards:

- Flame Spread rating - 20

- Smoke Development rating - 100

- 100% recycled wood fiber

- FSC mixed credit certified – AVAILABLE AS AN OPTION WITH AN UPCHARGE & CHAIN OF CUSTODY

- LEED® credit support: M&R 4.1, 4.2, 5.1, 5.2, 7 and EQ 4.4

- Third party certifi cation - SCS, EPP, Guardian

- CHPS compliant - California section 01350 approve

- Maximum 1 ¼” thickness

Celtec® Expanded Rigid Foam PVC/ Radius Applications

Celtec Displayboard is a foamed polyvinyl chloride (PVC) sheet whose extraordinary combination of features makes it ideal for signage, exhibits, store displays, POP, Kiosks, screen printing and more. The surface is a smooth matte finish that makes it ideal to paint or laminate to secondary substrates. Celtec also has good screw and staple retention which makes it ideal for stage prop design, cabinetry and other wood replacement projects.

Sheets are tough, high-strength and lightweight, and can be ordered in a wide range of sizes, thicknesses and colors. Celtec sheets are free of lead, cadmium, barium and zinc… and have passed all three UL 1975 requirements. Celtec is recommended for industrial and commercial signage. It readily accepts virtually any form of graphic overlay (print, paint and photo mounting). Celtec is also easy to cut and shape, making it a strong choice for three-dimensional exhibits, displays and stage sets.

- Lightweight Celtec is easy to handle, easy to work with.

- Low Flammability Celtec meets UL94 5V, UL 1975 and has a fl ame spread of 20 according to ASTM E84.

- Water resistant Celtec has a closed cell structure and has extremely low water absorption values.

- Surface Celtec’s smooth matte surface is ideal for graphics, printing and laminating.

- Weatherability Celtec is more color-fast than other foam PVC products.

- Strength Celtec has an excellent strength to weight ratio as shown in the screw and staple pull test data.

- Thermal Conductivity Celtec has excellent insulating characteristics.

- Safety Celtec contains no lead, cadmium or zinc.

- Maximum 30mm thickness

Extira

Extira is a revolutionary new-to-the-world material that is unique in three ways:

Extira is a panel product that resists moisture, rot and termites and offers excellent performance in exterior environments.

Extira can be used in any non-structural paint-grade EXTERIOR application. It also works well for high moisture interior environments.

Extira has a 5-year limited warranty, unprecedented in its product category.

Valchromat - Engineered colored wood

Wood fiber panel colored throughout. Innovative because it was the first product of its kind in the market and unique for its exclusive physical properties that set it aside and make Valchromat the star product of our company.

Thicknesses: 8mm, 19mm, other thicknesses available as special order.

Flakeboard

Premier® Plus HDF – Our standard HDF

The series refined fibers and elevated properties of our Plus product allow for a superior surface for critical applications such as thin paper laminates and thermally fused melamine, while its increased internal bond provides excellent results for the most intricate machining projects.

Premier® Fire Rated MDF

This fire-retardant panel is manufactured on our Premier Plus platform using a chemical system to achieve a fire-rated panel that is classified by Underwriters Laboratories for surface burning characteristics. Premier® MDF is ideal for commercial and institutional cabinets, paneling, case work and moulding trim when required by fire safety codes and architectural specifications.

Maximum thickness of 1 ½”.

Premier® FR has a Class A fire rating; Flame spread 15; Smoke developed 95

Cyro ACRYLITE® Acrylic

- Clarity - unsurpassed; up to 92% light transmission

- UV Resistance - usually withstands years of sunlight without yellowing

- Surface Hardness - high

- Colorability - easily made different colors, translucency, or opacity levels

- USP Class VI - most ACRYLITE gradesFD

ACRYLITE® acrylics by CYRO have up to the theoretical max. light transmission1, high surface hardness, and good UV resistance. All grades of ACRYLITE compounds are available in clear and a wide spectrum of transparent, translucent and opaque colors.

Panel Size

The standard panel size is 48” x 96” ( 4 x 8 ). Custom panels can be produced up to 60” wide and up to 120” long. Not all core materials are available in the larger sizes.

Panel Thickness

Panel thickness refers to the thickness of the raw stock prior to machining. After machining, the thickest area of the panel will be slightly less than this nominal panel thickness. Panel stock thickness ranges from 1/2” to 1 ½” . Many factors will determine the final panel thickness such as Pattern choice, installation methods and material availability.

Pattern Depth

The pattern depth refers to the deepest cut that is made in the raw stock in order to produce the pattern. Most patterns are offered in only one depth, however a few have multiple depth options as indicated on the specific pattern page.

Pattern Direction- EXTREMELY CRITICAL!!!

Most patterns can be produced in either vertical or horizontal orientation. Referring to the illustration at right, a pattern is said to be horizontal if the tool marks run generally the short direction and vertical if the tool marks run generally in the long direction. Please note that the vertical and horizontal designations have nothing to do with the installed orientation. For multiple panel layouts or panels that are approximately square, orientation should be indicated in an attached layout sketch. The direction of some patterns is not always obvious, so please refer to individual pattern photos in the catalogue to determine the preferred orientation.

More about this product

Categorised in Wood - Wall coverings - Wood panels - Wall panels - relief - MDF Medium Density Fiberboard.

Part of the collection

ART DIFFUSION® PANELS.

Manufacturer

Interlam

Family

Art Diffusion® panel Bio6F

Architonic ID

1076929

Similar products

This product has been archived. Product information may no longer be up to date.