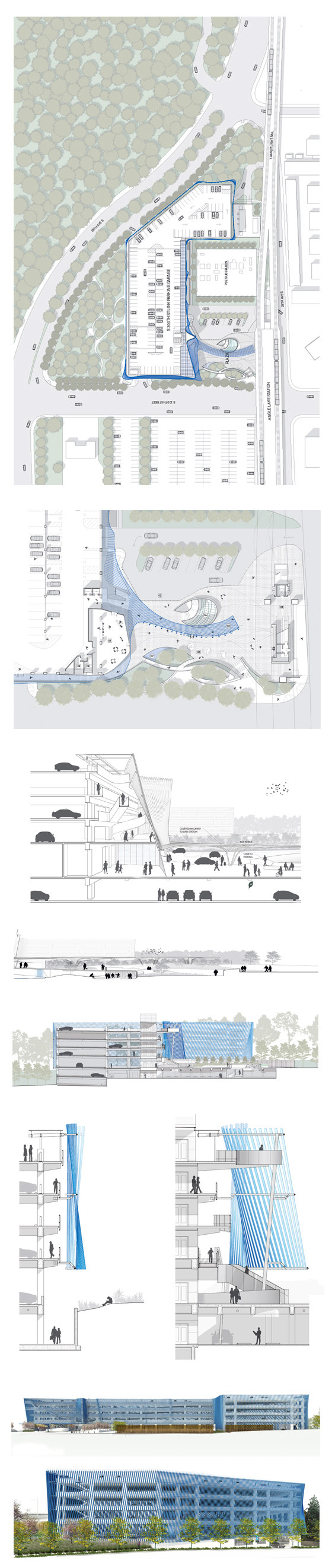

With ample space for people to live, work, and play, the new Angle Lake Transit Station and Plaza is an Envision certified sustainable mixed-use facility consisting of a 1-acre connecting plaza and community event spaces, a drop-off area for light rail users, retail space with dedicated bike storage and parking and a 35,000 square-foot parcel for future transit-oriented development. It also includes a parking structure for 1,150 cars designed to accommodate conversion to new future uses. Serving over 2,500 passengers daily, including the headquarters for Alaska Airlines, which employs more than 7,500 people in the immediate surrounds and over 4ooo people living within ½ mile of the station, Angle Lake Station is an important transit hub in the Sound Transit portfolio of transit facilities.

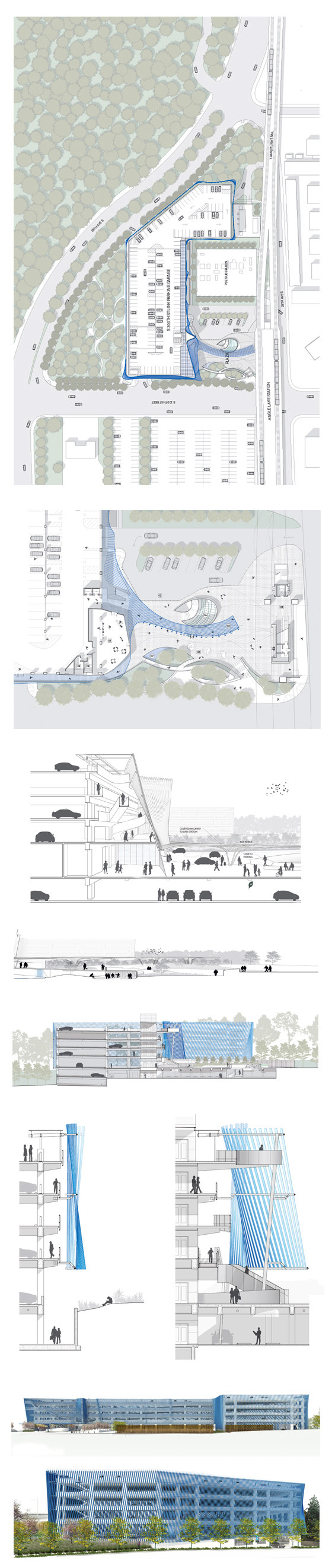

Inspired by William Forsythe’s improvisational piece ‘Dance Geometry’ where dancers connect their bodies by matching lines in space that could be bent, tossed or otherwise distorted, we began to think of the possibilities where simple straight lines are composed to produce an infinite number of movements and positions with little need for transition. This idea lessens the need to think about the end result and focus more on discovering new ways of movement and transformations’.

Using ruled surface geometry, the undulating façade is formed by connecting two curves with a series of straight lines to form the surface of the façade. Each of the custom aluminum façade elements were designed and segmented into standardized sizes for the most efficient structural shape and material form, while maximizing production, fabrication and installation cost efficiency. This technique allowed the design team to work with complex curved forms and rationalize them into simple, cost-effective standardized components, making them easy to fabricate and efficient to install. The entire façade was installed in less than three weeks without the use of cranes or special equipment.

Every unique condition of the project’s shape had to be geometrically rationalized. In other words, a fabricator must somehow measure and build off a set of drawings with the assumption that automated fabrication techniques are not always at hand. Beginning with the top and bottom chords, every segment of the curves was reduced to either measurable arcs for a pipe roller or straight-line segments for standardized shapes. Following this process, the lines of the ruled surface had to be segmented into standardized sizes for efficient fabrication while adhering to a set of rules given by the structural properties of the material. The architect provided analysis, constructability, and digital documents for direct and automated fabrication.

The seven acre 400,000 square foot mixed-use complex was the result of an international design/build competition. It features a seven-story, cast-in-place and post-tensioned concrete structure with an exterior façade that uses over 7,500 custom formed blue anodized aluminum façade panels. Using ruled surface geometry, the undulating façade is formed by connecting two curves with a series of straight lines to form the surface of the façade. Each of the custom aluminum façade elements were designed and segmented into standardized sizes for the most efficient structural shape and material form, while maximizing production, fabrication and installation cost efficiency. This technique allowed the design team to work with complex curved forms and rationalize them into simple, cost-effective standardized components, making them easy to fabricate and efficient to install. The entire façade was installed in less than three weeks without the use of cranes or special equipment.

With five levels above ground and two levels partially below ground the mixed-use structure takes advantage of the sloping site topography. It is accessible from three different street locations at various levels with 2,500 square feet of retail space at ground level and a 35,000-square-foot site to the west to support future transit-oriented development. As part of a multi-modal transit plan the station also has secure storage for bicycles with integrated lockers and racks and charging stations for electric vehicles.

The public plaza, on the third level, connects directly to the light rail entry, parking structure and public streets. It includes a passenger drop-off area, para-transit loading areas, and a covered walkway from the garage to the station. It forms a physical and visual connection between the project elements and includes several displays of regionally inspired artwork. Ornately designed seat walls, pathways, paving, native planting, and storm-water catchment features help to engage transit users as they move through the space, creating quiet places for social interaction while waiting for a transit connection. The plaza is designed to accommodate community events, such as festivals, farmers’ markets, art exhibits, and other outdoor public gatherings. The design and location of major project elements maximize function, sustainability, and aesthetics while providing an efficient use of space.

The 1.6 mile elevated light rail extension provides rapid public transit from the Seattle–Tacoma International Airport, the Rainier Valley, downtown Seattle, and the University of Washington.

Sound Transit

Brooks + Scarpa

Lawrence Scarpa, FAIA – Lead Designer, Angela Brooks, FAIA, - Project Executive, Mario Cipresso, AIA - Project Architect, Emily Hodgdon, Mark Buckland, Jeff Huber, AIA, Chinh Nguyen, Cesar Delgado, Fui Srivikorn, Christina Wilkinson, Royce Scortino, Sheisa Roghini, Soha Momeni, Ryan Bostic - Project Design Team

Landscape: Brooks + Scarpa and David Sacamano-BergerABAM

Engineering: BergerABAM – Structural Engineering,

Stantec– Electrical and Lighting

Sazan Group, Inc. - Mechanical

Luminescense – Lighting Design

BergerABAM – Civil Engineering

Security – Stantec

Shannon & Wilson – Geotechnical

Wayfinding: Brooks + Scarpa

Contractor: Harbor Pacific/Graham

Specifications: Brooks + Scarpa and BergerABAM

Façade Engineering: Brooks + Scarpa, Lars Holte, P.E., Walter P. Moore

Façade Fabrication: APEL Extrusions and Intermountain Industrial Fab