ZAC Moulon

Palaiseau, 2019

Project by

RiederThe greater Paris area is soon to be one of the top research and development regions in the world. Inspired by the success of Silicon Valley, a scientific and technological centre is being built south of the French capital. Facade panels and formed parts by the glassfibre reinforced concrete specialist Rieder from Austria were used on two important infrastructure buildings. The concrete skin facade with the new fomparts.fab product at the two energy centres in Moulon and Polytechnique is not only an architectural highlight, it also impressed planners and developers with its durability and ecological performance.

On an area of almost 2 million square meters, a visionary project is underway that combines many aspects of innovation and technological progress with resource-efficient living. From ecological construction methods and a future-oriented energy system to a sophisticated mobility programme - the aim here is to create perfect conditions in terms of sustainability in all areas of everyday life. The area will not only be home to research facilities, educational buildings and residential buildings, but also host sites for a variety of companies. The territory is intended to be an ecological flagship project for the whole world.

Green from the inside out

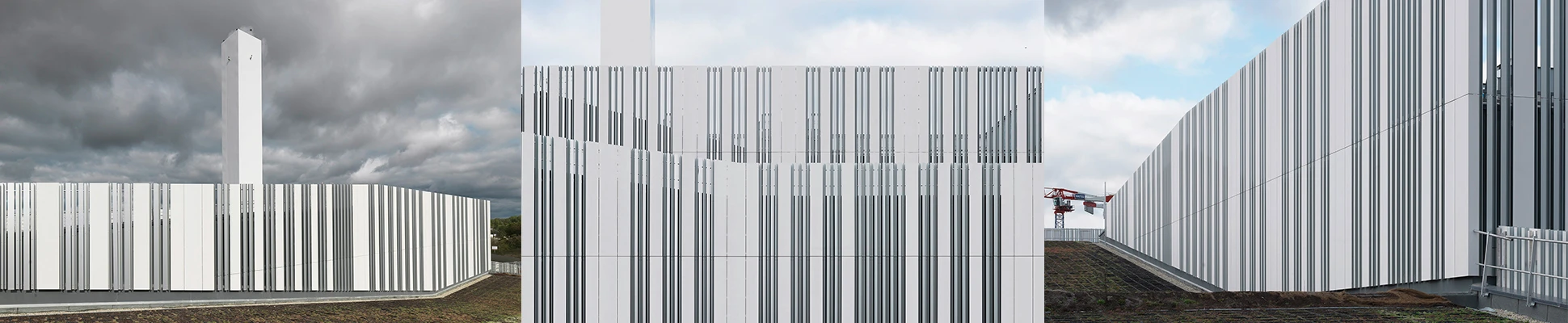

The intelligent low-temperature heat and cold network uses deep geothermal energy. It consists of two buildings which accommodate the central facilities. One of them is located in the Moulon district, and the other in the Polytechnique district. Special attention was of course also paid to sustainability when it came to the choice of materials for this and all other new buildings in the cluster. The concrete skin facade coupled with the new fomparts.fab at the two energy centres stand for innovation and sustainability. The uniform interplay of joints on the facade is particularly remarkable. Precise execution was a particular focus for the architects of Fricout-Cassignol. As the two technical buildings have no windows, the facade made of glassfibre reinforced concrete panels and sharp-edged formed parts from Rieder is particularly impressive. An exciting architectural detail of the building structure in Moulon is the transition of the facade to a semi-transparent part. At the upper section of the building envelope, the view through the gaps opens up to the green roof of the building, which is just as ecologically valuable.

Design diversity through innovation

For a variety of reasons, the concrete skin panels and the new formparts.fab product by Rieder are particularly well suited for the facade of the heating and cold stores of the Paris-Saclay cluster. For Rieder, future vision and sustainability are two of the most important aspects that drive the development of its products. The flat concrete skin panels come in a variety of different colours, surfaces and textures and can be used flexibly in a wide range of architectural contexts. In addition, the environmentally friendly facade panels made of glassfibre reinforced concrete impress the international market with their authentic materials combined with ecological foresight: It goes without saying that Rieder uses non-toxic products (free of crystalline silica) and reduces its use of primary energy in production to a minimum. In line with our zero-waste policy, for example, all waste materials from production are reused in other areas; innovative technologies help us reduce offcuts; when we do produce waste, it is utilised in product innovations made of waste cuttings which we developed ourselves. The greatest driving force behind our continuous development efforts is the striving to create more than just sustainable concrete products in order to allow us to make an active contribution to the energy revolution ourselves, such as the Paris-Saclay cluster.

The new formparts.fab are also made of the same robust and resource-saving glassfibre reinforced concrete. They complement the various design possibilities of the flat panels with a wide range of options for corners, edges and front-mounted facade parts. Due to their low weight and large span widths, Rieder formed parts are perfect for facades with challenging geometries.