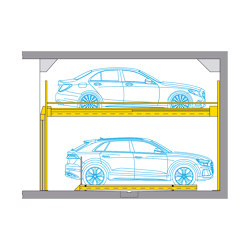

The parking platforms of both rows move together simultaneously to the left.

In order to lower the UL parking place no. 166 in the rear row, the start button on the operating device has to be pressed until the parking place is completely lowered.

In order to lower the UL parking place no. 166 in the rear row, the start button on the operating device has to be pressed until the parking place is completely lowered.

×A slider-puzzle Green Parking concept: Wöhr’s Combilift 552 system featuring parking arrangements up to three rows deep

By stacking and compacting the Wöhr Combilift Systems 543, 542 and 551, it is possible to create comfortable, space-saving parking solutions in the narrowest of spaces, with a high degree of user-friendliness. This sophisticated and ingenious product range has been perfected by the Wöhr Combilift 552 system, which can be installed wherever underground garages spaces are far deeper than they are wide and where it is therefore possible to park vehicles behind one another in consecutive rows.

In the construction of a new apartment and office building in the Hackesche Höfe courtyard complex in Berlin, this combination has been cleverly deployed by local Architects THOMASMÜLLER IVANREIMANN: in the “An der Spandauer Brücke” underground garage, a total of 76 new parking spaces have been provided with the installation of the Wöhr Combilift 551 and Combilift 552 systems in a two-row deep layout arrangement.

In as far as the system control engineering is concerned, the two systems work as one. Via a central operation device, all the system parking places are selected using a coded key that is allocated individually to each single User. In the event of vehicle parking and retrieval processes, the User simply selects his/her parking place through the central operation device. Whether it is located in the topmost level of the deepest-set parking row, by simply pressing on the start key, the system starts up and the parking process is activated.

Access to the rearmost parking row may be cut off by a parking platform that is in the way: it is automatically detected by the clever Combilift controls which simultaneously shift the parking platforms belonging to both system rows to the left.

Once the end position is reached, the selected parking place in the rearmost parking row is lowered and can be driven into and occupied. After a lock-time interval of approximately 30 seconds, the Combilift is ready for the next parking process.

Another intelligent, space-saving solution devised by Wöhr: 76 conventional parking spaces would require a surface area of approx. 1567 m² – with the Wöhr Combilift, only approx. 964 m² are necessary.

Further information on the Wöhr Combilift 551/552 system operations and advantages is available in Wöhr’s new “Hackesche Quartier Berlin district - an der Spandauer Brücke” Project Report.

After securing the vehicle, the user gets out of the car and leaves the system.

Once the parking platform has been lowered, the user can remove the key from the operating device. The user has a 30 second lock-time interval to drive out of the system, during which no other parking selection can be started.

Once the parking platform has been lowered, the user can remove the key from the operating device. The user has a 30 second lock-time interval to drive out of the system, during which no other parking selection can be started.

×