De Castelli: Metal at its finest

Brand story by Alyn Griffiths

Crocetta del Montello (TV), Italy

12.09.16

With passion and innovative processing technology, the Italian firm DE CASTELLI brings the ancient material of metal to an unexpectedly modern level.

De Castelli works with architects to realise their visions in metal, such as Cino Zucchi’s sculptural entrance to the Italian Pavilion at the 14th International Architecture Exhibition in Venice

De Castelli works with architects to realise their visions in metal, such as Cino Zucchi’s sculptural entrance to the Italian Pavilion at the 14th International Architecture Exhibition in Venice

×People have been processing, forming, cutting and joining metal for millennia to produce functional and decorative items that have played a key role in our cultural evolution. Mastering this malleable material requires great skill and a thorough understanding of its physical properties. Fortunately for Italian brand De Castelli, its founder Albino Celato is the fourth generation of a blacksmithing bloodline, and his passion for metal is translated into the company’s innovative products and surface materials.

Celato founded De Castelli in 2003 in the small town of Crocetta del Montello near Treviso. Rather than focusing solely on the traditional metal processing skills developed by his forebears, he wanted to make metal a material for the modern era by foregrounding progressive design and technologies. The result is a catalogue of products, furniture and surfaces that combine traditional craftsmanship with advanced engineering and manufacturing techniques.

One of De Castelli’s stated aims is “to bend metal to the requirements of different spaces and uses, to shape it to the tastes and desires of a sophisticated and demanding clientele”. The company sources and manipulates metals including copper, brass, iron and steel to meet the specifications of architects and designers looking for unique surface finishes. The durability and versatility of these materials makes them suited to use on walls, ceilings or floors, and De Castelli is regularly called on to advise its clients on the optimum metal to enhance their project.

Architectural projects like Marco Zito + Alessandro Pedron’s OVS & Excelsior Pavillons at Expo Milano 2015 can benefit from the sturdy finishes and tactile properties of metal cladding systems

Architectural projects like Marco Zito + Alessandro Pedron’s OVS & Excelsior Pavillons at Expo Milano 2015 can benefit from the sturdy finishes and tactile properties of metal cladding systems

דThe added value of De Castelli is that we shape this material according to the design of the architect, designer or artist,” says the firm’s research and development manager, Filippo Pisan. “Starting from a sketch or an idea, we can fulfil the architect’s design project, as the entire engineering and development is done by our in-house technical department. This means the architect or designer doesn’t need to be a metal expert.”

Some of the projects for which De Castelli has provided its expertise and materials demonstrate the firm’s capacity to translate imaginative concepts into reality. At the 2015 Milan Expo, the company worked with architects Marco Zito and Alessandro Pedron to develop cladding for the fair’s OVS & Excelsior Pavillons. A system of overlapping lozenge-shaped panels in Délabré Corten steel lent the structure’s facades an eye-catching three-dimensionality, with a subtle texture and tone that weathered gradually.

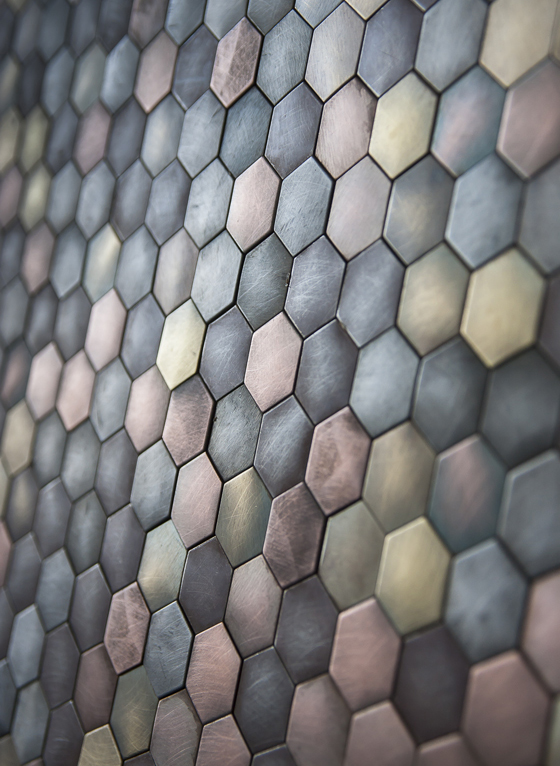

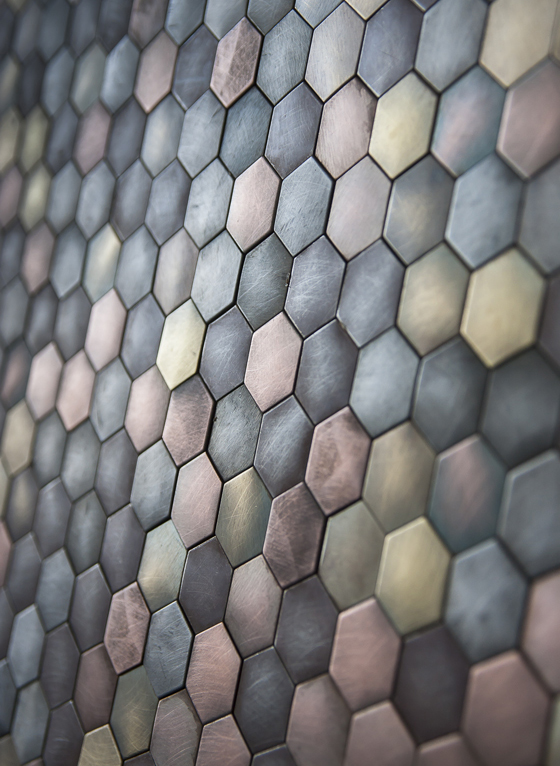

De Castelli uses a combination of the latest technologies and traditional craftsmanship to shape metals including copper, steel, iron and brass to the specifications of its collaborators

De Castelli uses a combination of the latest technologies and traditional craftsmanship to shape metals including copper, steel, iron and brass to the specifications of its collaborators

×For the 14th edition of the Venice Architecture Biennale in 2014, De Castelli created a grand entrance arch for Cino Zucchi’s Italian Pavilion. The 10-metre-tall portal was covered in 163 steel panels that aimed to enhance “the expressive potential of the metal, thanks to the development of a special finish that highlights the typical colour range of steel – from grey to brown to blue.”

In addition to supporting bespoke architectural projects, the company produces a broad range of metal surfaces that make its hand-crafted materials available to anybody. Each of these products is precisely manufactured using methods such as laser cutting, bending and welding, combined with unique finishing techniques including burnishing, oxidisation and brushing. “Every process is completed with the highest level of skill,” adds Pisan, “as if by a blacksmith with the sensibility of a jeweller.”

For internal use, the company manufactures a range of metal products that can be used as wall or floor coverings. Designs such as Copycat and Vertical Green demonstrate the material’s artistic potential

For internal use, the company manufactures a range of metal products that can be used as wall or floor coverings. Designs such as Copycat and Vertical Green demonstrate the material’s artistic potential

×The metal surfaces De Castelli manufactures are suited to use in domestic or commercial environments. Some are developed specially for indoor or outdoor use, while others can be applied in either setting. Familiar materials such as polished stainless steel and natural black iron are offered alongside more unusual finishes like délabré brass, which undergoes an oxidation treatment to lend it special chromatic effects.

Weathering steel, mottled copper and hammered brass exemplify the intricate hand-finishing methods that can be applied to lend texture and tactility to the surfaces. For more personalised decorative details, metal plate can be precisely engraved with bespoke patterns or branding, while laser cutting also offers an opportunity for drawings and designs to be etched into the materials.

Furniture and lighting offers an opportunity for De Castelli to apply its fine craftsmanship and precise detailing to products suited to use in contemporary homes

Furniture and lighting offers an opportunity for De Castelli to apply its fine craftsmanship and precise detailing to products suited to use in contemporary homes

×Contemporary design is a core aspect of De Castelli’s brand identity, and the company has developed its own range of furniture and products to express how much importance it places on developing relationships with the world’s leading creative talents. These bookcases, storage units, lights, chairs and tables apply metal in surprising ways, resulting in objects that are crafted with the same precision and attention to detail as the company’s core surface materials.

Examples of De Castelli’s designer collaborations include Nikita Bettoni’s Solometallo console, which combines copper, brass and stainless-steel surfaces with turned aluminium legs, lacquered wood and leather to create an object of rich visual and textural diversity. Marco Zito’s Ginko collection of sculptural outdoor lights highlights the intriguing detail of the metallic surfaces by directing light onto leaf-shaped reflectors, while the monolithic Celato storage unit, which was developed by the firm’s in-house design team, incorporates hidden drawers into its panelled shell. Ongoing collaborations with famous names such as Xavier Lust, Ron Gilad and Michele de Lucchi are also helping to establish the brand as an important player on the global design scene.

The classic yet characterful design of the Yoroi sideboard by Alessandro Masturzo exemplifies De Castelli’s passion for developing products that give metal a new and surprising form

The classic yet characterful design of the Yoroi sideboard by Alessandro Masturzo exemplifies De Castelli’s passion for developing products that give metal a new and surprising form

×From original furniture created by top designers to one-off artworks and large-scale architectural commissions, De Castelli is steadily forging a reputation as Europe’s leading innovator in metallic surfaces. The brand currently operates showrooms in Milan and Shanghai, where visitors can experience the materials and craftsmanship first hand, and is looking to expand into new territories.

According to Pisan, improving awareness of the company’s products across the globe is key to De Castelli’s future growth. “We have a worldwide sales network and the objective is to expand the commercial network, covering areas in which we are not yet present and exporting the know-how of De Castelli in architectural studies,” he points out. If this target is achieved, architects and designers all over the world will soon be given the chance to explore contemporary uses for this ancient material.

© Architonic