Sobre Armourcoat

DESCUBRE MáS SOBRE ARMOURCOAT

Armourcoat has become an integral part of some of the world's most prestigious architectural projects. Now, as the world's most foremost supplier of polished plasters and a leading provider of innovative surface finishes and sculptural effects, Armourcoat is proud to write the latest chapters in the history of polished plaster.

Imagine the merits of a decorative surface finish possessing a strength and brilliancy and an excellence that will last to a great age. That was the vision of coloured and polished plasters depicted more than 2000 years ago in the Discourses of Vitruvius, one of the great architects of ancient Rome. Two thousand years on, Armourcoat's range of Polished Plasters combines ancient skills with modern materials and carefully refined application techniques, to create a stunning range of polished plaster finishes unsurpassed in hardness and quality.

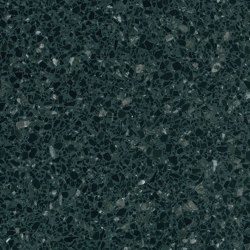

Armourcoat's smooth polished finish is similar to the marmorino stucco, used extensively in northern Italy during the Renaissance period as an internal and external wall finish and as a background for the ornate frescoes which dominated much of the decoration of that time. It is this combination of material and technique that is now widely regarded as Venetian plaster. The final appearance of this finish is very dependent on the hand of the individual applicator, making it possible to achieve anything from a plain, lightly polished surface to a more highly burred and marbleised effect.

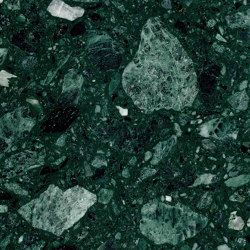

The origins of Armourcoat’s luxurious Spatulata finish dates even further back in history. Pioneered by the Egyptians; improved by the Romans; it became known as stucco lustro veneziano by the Venetians. Traditionally it was applied in 10-15 fine coats over a background of 2-3 layers of semi-dry marmorino and finally polished with hot irons. Modern additives have greatly improved the working characteristics enabling it to be successfully applied in just 5-7 layers and polished to a glassy shine with a small steel blade or trowel. Spatulata is a unique mix of high-grade aged lime putty, micronised marble powder and special additives. For many, it is the ultimate Venetian stucco; certainly the one with the highest sheen and the most intriguing texture.

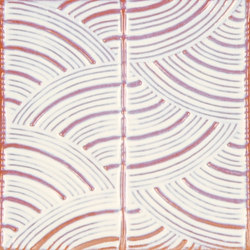

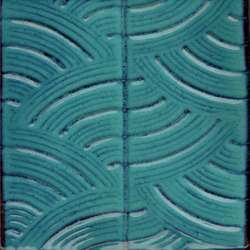

For centuries, the colour in Venetian Polished Plasters has come from natural earth pigments. Unfortunately, nature does not work to a fixed formula and using them has always been a complex business because of colour inconsistencies and variable pigment strengths. For this reason, colourists were traditionally employed for mixing and matching, turning all polished plaster recipes into expensive, bespoke finishes. Armourcoat Limited operates strict quality control programmes throughout manufacture. However, Polished Plaster application remains very much a manual craft, every craftsman having his own signature finish or ‘hand’. Thus, the skills that create the beauty of Polished Plasters can subtly change the hue and pattern of the finish. The more heavily the plaster is trowelled, the deeper the tone and patterning will be.

It is this individual touch that characterises Polished Plaster and makes it such an exciting and vibrant finish. It is also why Armourcoat Limited recommends most strongly that agreement on colour, style and texture be established prior to the start of a contract by the approval of a contract control sample.

Armourcoat has become an integral part of some of the world's most prestigious architectural projects. Now, as the world's most foremost supplier of polished plasters and a leading provider of innovative surface finishes and sculptural effects, Armourcoat is proud to write the latest chapters in the history of polished plaster.

Imagine the merits of a decorative surface finish possessing a strength and brilliancy and an excellence that will last to a great age. That was the vision of coloured and polished plasters depicted more than 2000 years ago in the Discourses of Vitruvius, one of the great architects of ancient Rome. Two thousand years on, Armourcoat's range of Polished Plasters combines ancient skills with modern materials and carefully refined application techniques, to create a stunning range of polished plaster finishes unsurpassed in hardness and quality.

Armourcoat's smooth polished finish is similar to the marmorino stucco, used extensively in northern Italy during the Renaissance period as an internal and external wall finish and as a background for the ornate frescoes which dominated much of the decoration of that time. It is this combination of material and technique that is now widely regarded as Venetian plaster. The final appearance of this finish is very dependent on the hand of the individual applicator, making it possible to achieve anything from a plain, lightly polished surface to a more highly burred and marbleised effect.

The origins of Armourcoat’s luxurious Spatulata finish dates even further back in history. Pioneered by the Egyptians; improved by the Romans; it became known as stucco lustro veneziano by the Venetians. Traditionally it was applied in 10-15 fine coats over a background of 2-3 layers of semi-dry marmorino and finally polished with hot irons. Modern additives have greatly improved the working characteristics enabling it to be successfully applied in just 5-7 layers and polished to a glassy shine with a small steel blade or trowel. Spatulata is a unique mix of high-grade aged lime putty, micronised marble powder and special additives. For many, it is the ultimate Venetian stucco; certainly the one with the highest sheen and the most intriguing texture.

For centuries, the colour in Venetian Polished Plasters has come from natural earth pigments. Unfortunately, nature does not work to a fixed formula and using them has always been a complex business because of colour inconsistencies and variable pigment strengths. For this reason, colourists were traditionally employed for mixing and matching, turning all polished plaster recipes into expensive, bespoke finishes. Armourcoat Limited operates strict quality control programmes throughout manufacture. However, Polished Plaster application remains very much a manual craft, every craftsman having his own signature finish or ‘hand’. Thus, the skills that create the beauty of Polished Plasters can subtly change the hue and pattern of the finish. The more heavily the plaster is trowelled, the deeper the tone and patterning will be.

It is this individual touch that characterises Polished Plaster and makes it such an exciting and vibrant finish. It is also why Armourcoat Limited recommends most strongly that agreement on colour, style and texture be established prior to the start of a contract by the approval of a contract control sample.

DESCUBRE MáS SOBRE ARMOURCOAT