Koch Membranen is a pioneer in the field of textile architecture. Headquartered in Rimsting am Chiemsee and now run by its fourth generation, the company has been spearheading solutions in textile architecture and interior design. They have accumulated their extensive know-how over the course of several decades, managing challenging projects, cooperating with architects around the globe and building structures with all sorts of materials.The clear advantages textile building materials hold over classic materials come to full effect in the custom turn-key solutions the company has created for their customers at home and abroad: They have no equal when it comes to translucence, low weight, creating large surfaces with minimum material requirements or options to create an abundance of shapes and designs.

Leer másColecciones

Ver todas las coleccionesProductos destacados

Ver todos los productosAspecto destacado del proyecto

Ver todos los proyectos

Koch Membranen

2019

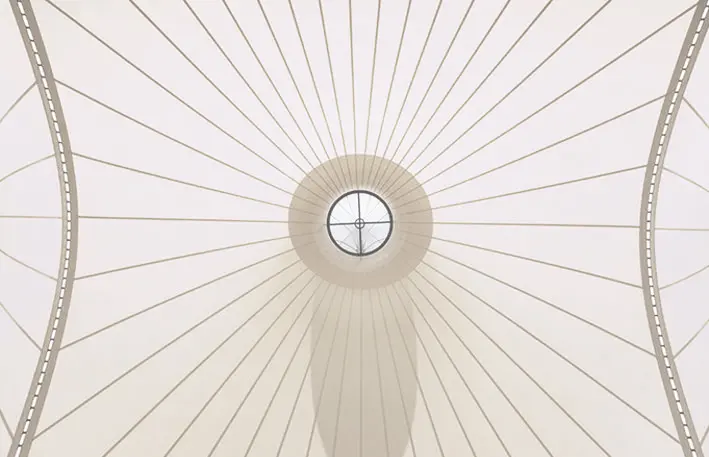

Ohlsdorf Hamburg

Lee más sobre Koch Membranen

Ver todos los artículosAcerca de Koch Membranen

Koch Membranen is a pioneer in the field of textile architecture. Headquartered in Rimsting am Chiemsee and now run by its fourth generation, the company has been spearheading solutions in textile architecture and interior design. They have accumulated their extensive know-how over the course of several decades, managing challenging projects, cooperating with architects around the globe and building structures with all sorts of materials.The clear advantages textile building materials hold over classic materials come to full effect in the custom turn-key solutions the company has created for their customers at home and abroad: They have no equal when it comes to translucence, low weight, creating large surfaces with minimum material requirements or options to create an abundance of shapes and designs.

Koch Membranen ranks among the world's few companies who are capable of processing all membrane materials available on the market and who tailor and, at times, hand craft these materials in their own production facility. This design and production manufactory allows for a seamless end-to-end production process – from consultations to find the right material to planning to final assembly and maintenance. This comprehensive approach is pivotal to delivering quality that shows in the finest detail and solutions that marry attractive architecture with sound technology and offer superior durability. Relying on state-of-the-art technology, the computer-assisted machining of the membranes delivers results that are exact to the millimetre. The company's Rimsting production location also constantly pushes the limits of material design. Armed with the knowledge attained from a wide variety of production and machining processes, the company has teamed up with weaving mills and other membrane manufacturers to optimise and enhance the products, e.g by improving their reaction to flexure or by enhancing light transmission or joining technology.

The materials that can be processed range from heavy fabrics of exceptional textile strength to razor-thin membranes for use in interior areas or aviation. Once tested for their suitability for the project at hand, the materials undergo a high-quality manufacturing process that involves bonding, welding, sewing or joining by mechanical methods. Depending on the required design and application, the materials used may be composed of non-coated, coated or laminated fabrics, scrim or foils. The company also offers specially designed light and acoustic fabrics under the brands of Artex®, Helioflon® and Siglatex®, which are used primarily in textile interior design.