Productos por Morbern Europe

Ver todos los productosColecciones

Ver todas las coleccionesCatálogos

Ver todos los catálogosLee más sobre Morbern Europe

Ver todos los artículosMarcas similares a Morbern Europe

Ver todoExplora nuestro catálogo

Ver todoAcerca de Morbern Europe

About Morbern

With over 50 years experience in the design and manufacture of coated fabrics, Morbern is your partner of choice for all decorative upholstery projects. Our innovative products combine style and performance to fulfil your requirements across markets and applications.

Morbern’s total commitment to greener living and eco-friendly solutions makes it a leader in the supply of sustainable vegan leather.

Cutting-edge digital print capabilities complement a wide range of stock collections, developed with our customers in mind and supported around the world by dedicated teams, to offer you service with a difference.

Company history

Originally established in 1956 by partners MORis Bloomfield and BERNie Stein as a lamination business, the present day version of Morbern – one of the first expanded vinyl manufacturers in the world – started in 1964, in Cornwall, Ontario. Five years later, the partners sold the company to Whittaker Corp before David, Morris Bloomfield’s son, purchased the business back in 1976. The rest is – family– history and, in 2014, Morbern celebrated 50 years expertise in coated fabrics.

Morbern Europe

Morbern started its European sales operations in 2014, underpinned by a dedicated warehousing & logistics platform in Amsterdam. From there, over 500 SKUs are sold through a wide distributor network and shipped daily across Europe & beyond.

The cross-market expertise and dedication of Morbern Europe’s multi-lingual sales & support team makes for a total every-step-of-the-way customer satisfaction experience, from product conception & design to delivery.

Quality

As a vertically integrated, ISO 9001:2015 certified company, Morbern’s focus has always been on delivering high quality design and performance upholstery solutions for the Contract, Healthcare, Hospitality, Marine, Outdoor, Automotive, Recreational and Transportation markets. But it takes more than incredible products to make a great company: Morbern complements manufacturing capability with world-class research, design and support services.

Service

Today, the privately-owned family company, now in its third generation, continues to put customers and service at heart of its operations:- Four manufacturing plants

- Strategic warehousing locations & extensive logistics network to offer prompt and reliable deliveries

- Large inventories of the most popular product ranges at all Morbern storage facilities around the world

- Custom stocking programs for “just-in-time” supply

- Short production lead times for urgent & made-to-order projects

Headquartered in Ontario, Canada, Morbern is present on 3 continents – North America, Asia and Europe – to best meet the requirements of each market and firmly place Morbern on the international suppliers map.

Products

Coated Fabrics are textiles that have been treated to make them stronger and longer lasting. Vinyl coated fabrics are extremely hard-wearing and not prone to peeling or cracking, as is often observed with PU fabrics due to their poor hydrolysis resistance.

For over 50 years, vinyl has been used in various applications including to line potable water reservoirs and pipes. It is the material of choice for the production of blood bags and intravenous tubes.

Unlike other polymers such as PU, 50% of PVC (vinyl) is made up of common salt – this makes it less reliant on fossil fuel and easily recyclable.

Large quantities of vinyl are re-melted into many useful products and, in contrast to Silicone, numerous vinyl-recycling facilities can be found all over the world.

PVC IS A SUSTAINABLE PRODUCT BECAUSE…

- easily recyclable and energy-efficient to manufacture

- low consumer of non-renewable resources

- offers durable, long life-cycle solutions reducing the need for constant product replacement

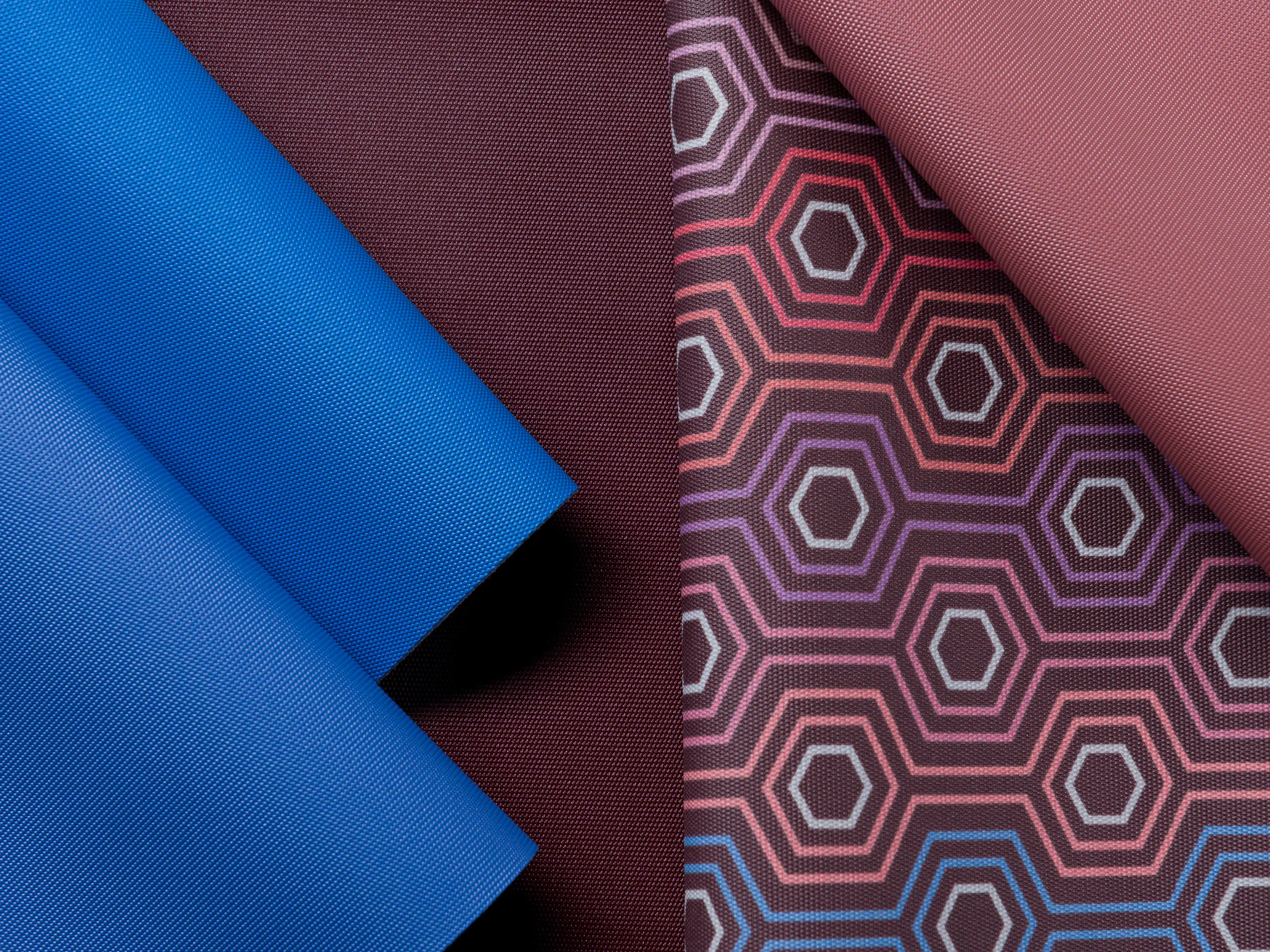

High Resolution Digital Print

Printing on vinyl is not exactly difficult but real expertise is required to achieve high resolution printing capable of withstanding high seating traffic, rigorous cleaning and all-weather environments. Morbern has perfected the durability of printed vinyl by adding proprietary wear layers over the digitally applied ink. This enables the Martindale abrasion to meet 300,000 cycles – much more than any other digitally printed product on the market – and also provides excellent bleach resistance, thereby enhancing cleanability.

The tonal palette and custom design options are infinite due to the ability to precisely apply the primary ink droplets. Many R&D hours spent on laboratory trials have achieved a vibrant, crisp colour and resolution of up to 1080dpi.

Digital print patterns are available in 4 different embossing textures, offering an additional choice of finish. From hospitals to corporate offices, boutique hotels to restaurant chains or RVs to public transport, Morbern digital print coated fabrics cover, enhance and protect interior and exterior surfaces to your exact design specifications. All digital print fabrics are IMO MED compliant.

With a low minimum run quantity of 300m, bespoke decors are no longer confined to the mood board.

Innovation

For over 50 years, Morbern has been at the forefront of innovation, creating real breakthroughs in the performance fabrics industry. From the MorCare healthcare performance vinyl revolution of the 1990’s to today’s cutting-edge Digital Print technology, from the introduction of Allante, the first luxury-hand faux leather on the market, to the enhanced Touch with superior denim-dye cleanability, Morbern consistently delivers value-added products. In addition to working directly with customers to create tailor-made solutions, Morbern partners up with universities such as Queen’s University, Canada and other organizations for R&D projects that advance manufacturing and product capabilities.

Ethos

From our Phthalate-free production in Canada, where continuous sustainability initiatives have already underpinned our environmental promises, to our ambitious plans for greater & greener achievements, Morbern’s ethos is one of total commitment to help protect the planet and preserve our children’s tomorrows while meeting our clients’ needs today. Morbern continually looks for ways to reduce the environmental impact of its product and processes:

- we were among the first manufacturers of coated fabrics to completely eliminate heavy metals such as lead and cadmium from our production

- we ensure that the water flowing out at the end of the manufacturing process is clean enough to drink and new closed-loop cooling circuits installed in 2016 reduced our water consumption by more than 75%.

- we are fully committed to better controlling our emissions and improving the air quality of our surrounding community. Low VOC (volatile organic compounds) water-based top coat finishes have now replaced most solvent formulations.

- most of Morbern products are phthalate-free, using bio-based renewable ingredients derived from soya beans.

- our dedicated second-quality team redirects material to other markets and applications so that it is kept out of landfill sites.

- Morbern products are REACH and RoHS compliant.

- 99% of the energy (hydroelectric power) used by the Morbern production plant is renewable

- Morbern is committed to achieve ISO14001:2015 Environmental Management certification by end of 2020

- Morbern’s wide product range includes green PVCs: free of phthalates, fire- & anti-bacterial additives, coated on recycled backing fabrics.

COATED FABRICS – ALSO KNOWN AS VEGAN LEATHER – ARE AN ETHICAL ALTERNATIVE TO ANIMAL HIDES THAT REQUIRE A LOT OF ENERGY AND CHEMICALS TO BE CONVERTED INTO LEATHER.

THE FR-FREE REVOLUTION

Since 2015, some Contract & Healthcare projects in North America have started specifying materials without flame-retardant (FR) additives.

At the request of the design community, Morbern created Maverick, a durable FR-free vinyl with a simple leather texture.

Today, to meet a growing demand for greener living and eco-friendly solutions, Morbern has expanded its FR-free product range and launched a MorGreen collection at Neocon 2019, Chicago.

Thanks to their inherent flame-retardant properties, some FR-free coated fabrics still comply with the EN1021 (Parts 1 & 2) European fire standard: Eden FRee.