FiDU is a technology taking advantage of the stability and strength of the metal sheet along with low self weight and low waste of material. A feature like that could perfectly serve in an energetic sector, where there is need of diverse sustainable and decentralized sources of energy.

Thinking of a ‚portable’ energy source in FiDU the obvious solution was to produce a wind turbine with fins that could be perfectly aerodynamic and light or even inspired by natural bionic shapes.

The inspiration for the research team to build the assymetrical profile was the latest research about the aerodynamics of the whales’ fins. To reach the best aerodynamics not all the form was inflated. The blades were divided into inflatable compartments or inflated partially while leaving the rest of the element flat.

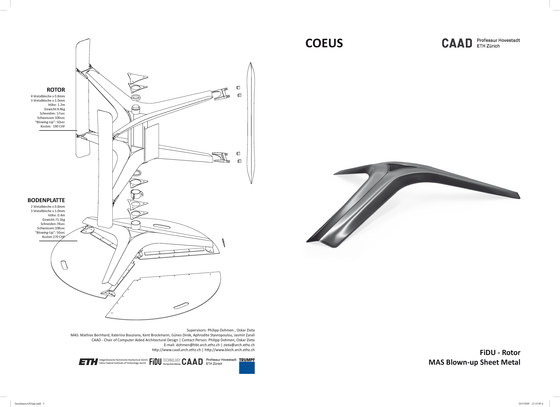

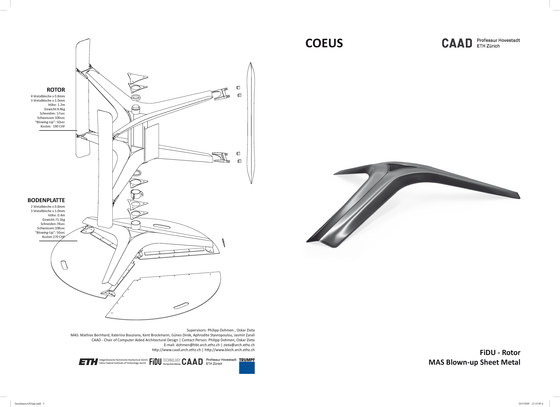

In the search for possibilities concerning renewable energies, a wind turbine is demonstrated which can be produced using FiDU technology. A Vertical Axis Wind Turbine (VAWT) format was chosen since they can operate efficiently without sophisticated and expensive equipment to orient them into the wind. They are often more flexible in their design and have a wider range of applications than horizontal turbines with regards to the potential to decentralize yet upscale the capacity for energy production. Pound for pound, FiDU elements are much more efficient than comparably performing components and due to their low weight, their transport and assembly are much easier. By using the FiDU technology, many costs associated with wind turbine operation can be reduced. The aim of this research is to bring these elements to production level.

The dimensions and proportions were based on existing studies of free-standing wind turbines. Models were used to test which forms and contours resulted in the desired profiles. Three separate wing designs were subsequently advanced and developed: a single-chamber, triple-chamber and a waveform wing. These designs lead to different approaches regarding the connection of the three-armed support. The production of the primary components of the wind turbine was accompanied by a search for suitable assembly methods. The biggest assembly challenge was combining the deformed FiDU elements in a precise and stable manner (rear side). The resulting wind turbine is 2.30 meters high, has a diameter of 1.60 meters and a total weight of 80.5 kilograms.

Kamm hanger: a part of the research

The research on the aerodynamic forms inspired Zieta Prozessdesign’s team to create a usable home product – a hanger made of ‘fins’. Each product is a new test for the FiDU technology and so the Kamm hanger form was first made to test how a non-symmetrical form with waves can be welded and deformed in FIDU. The further research brought a manifest-product: Kamm hanger.