Slenderness in Steel: the unico XS profile system

Historia de la marca de Ulrich Büttner

Arbon, Suiza

11.08.15

Forster Profilesysteme AG, headquartered in the Swiss town of Arbon, still occupies the site where it was founded over 140 years ago.The original coppersmith shop of F.J. Forster has long since developed, however, into an innovative company with extensive know-how in stainless-steel processing and profile-system development.

Forster unico XS is ideal for use in historical buildings when it comes to replacing traditional, small-paned glazing in industrial buildings with insulated products – such as here at the Löwenbräu-Areal in Zurich

Forster unico XS is ideal for use in historical buildings when it comes to replacing traditional, small-paned glazing in industrial buildings with insulated products – such as here at the Löwenbräu-Areal in Zurich

×Forster Profilsysteme AG offers five product lines: thermally insulated systems for doors, windows, for curtain walls and glazed roofs, systems for fire and smoke resistance, security applications, and systems without thermal breaks for doors and windows. The products are, therefore, without exception, for use in buildings. Construction planners are familiar with and appreciate the steel product lines, not least because of their extremely narrow profiles compared with other products.

The people at Forster's are particularly proud of a relatively new development, namely the Forster profile system called unico XS that offers ultra-slim facings and, at the same time, like all Forster unico profiles, does not require any insulating plastic bridge for the thermal separation of the inner and outer window frame. Forster unico manages to replace this otherwise obligatory component of metal frames with a point-welded thin steel web profile. ‘Just the formulation of the idea of such a product alone shows courage; but actually turning this idea and the essential production steps on the machine into reality was a challenge,’ explains Fosca Roman, Forster's Marketing Manager.

But just coming up with the simple idea of a steel web wasn't enough. A regular and howsoever-designed web profile in the traditional sense would, of course, have offered a thermal bridge of the first degree. In addition, high demands were made as regards load capacity and rigidity, which the web was supposed to meet. That's why a ‘profile’ consisting of intersecting filigree rods or sheet metal blanks welded together using laser spot technology, was the solution: a minimal thermal bridge effect, high stability, flawless recyclability.

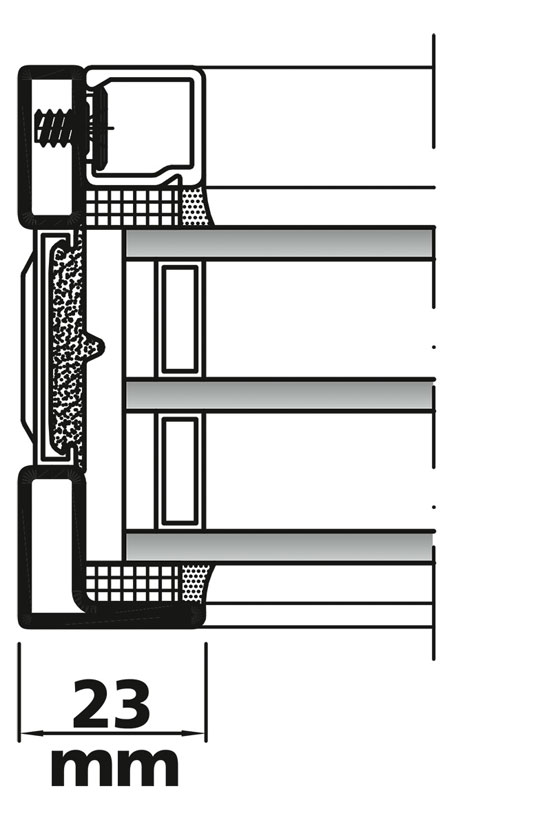

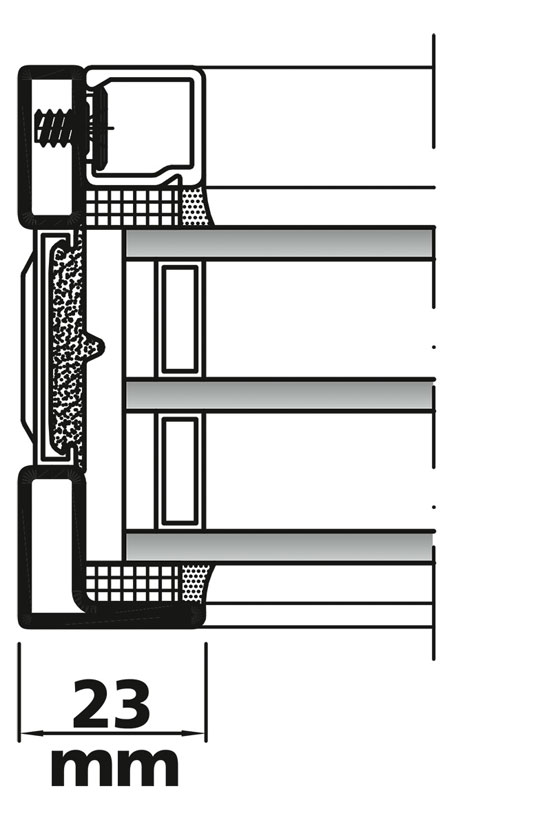

The narrowest profile – just 23 mm wide – can even hold vertical triple glazing. The section shows the steel web of thermal separation with a plastic seal. The aluminium glazing bead can also be made of steel if so requested

The narrowest profile – just 23 mm wide – can even hold vertical triple glazing. The section shows the steel web of thermal separation with a plastic seal. The aluminium glazing bead can also be made of steel if so requested

×What astounds one at first is the fact that the system’s narrowest facing width – the sensational 23 mm for vertical triple glazing – is actually achieved independently of this construction of thermal separation. Thanks to Forster’s unico XS, the product developers quite rightly regard themselves as being in the vanguard when it comes to slim window profiles made of steel.

‘The slim form results, on the whole, from our development. As slim as possible and, at the same time, as load-bearing as possible – that's our world. The trend is already moving towards ever “less” and ever slimmer. No architect wants wide frames and posts in his façade; and, with our very fine profile, we're taking a great step towards accommodating this trend.” Of this Fosca Roman is convinced.

At the same time, Forster had its sights on a special niche: historic buildings whose original windows have many small panes of glass surrounded by ultra-slim steel profiles. Whether it's a matter of a casino palace or an industrial monument, when the building was erected, there was no talk of thermal insulation or heat-transfer coefficients. This historical building fabric, with its filigree cassette windows, can now be renovated in such a way that it retains its authenticity, but still acquires sensible energy-saving features. If the people in charge of the care and preservation of ancient monuments would accept this technical innovation, it would open a wide gate, and although the old window frames are not of a uniform width, the 23 mm width of unico XS comes very close to the originals.

With the Casino de Monte Carlo in Monaco, the aspects of design and energy efficiency were also very much the centre of attention. Very similar to the original model, the glazing has horizontal panes and, in part, arches

With the Casino de Monte Carlo in Monaco, the aspects of design and energy efficiency were also very much the centre of attention. Very similar to the original model, the glazing has horizontal panes and, in part, arches

×In this context, the flexibility of Forster unico XS profiles is an important and welcome feature. Arched windows and other special shapes are no longer a terrifying prospect. The manufacturer specifies in his documents the smallest possible size of casement: 35 cm x 45 cm. As with the minimum pane size, it is not the fittings technology alone that determines a minimum dimension, but also the geometry of the spacer profile, which only develops its stability as of a minimum length and the appropriate number of weld points.

What seems so logical and “easy” in the end required time-consuming development despite all the expertise acquired over decades – not only as regards drawing skills, but also practical ones. The development of Forster unico XS took one and a half years. “The system of profiles plus all accessories and small parts have to be designed in such a way that a metalworker can install windows and glazing after simple training. Our own people can easily assemble something. The art in all this, however, is developing something new that leaves a lot of creative freedom, yet remains easy to work with and, on top of that, is rapidly and successfully accepted by the market. When handling gets too complicated or expensive, no-one will want it – despite all these advantages. No matter how beautiful it is,” Fosca Roma concludes.

The Maison des pratiques artistiques amateurs MPAA in Paris is an old industrial building. In the course of its renovation, thermally insulated glazing using Forster unico with integrated vent casements was fitted

The Maison des pratiques artistiques amateurs MPAA in Paris is an old industrial building. In the course of its renovation, thermally insulated glazing using Forster unico with integrated vent casements was fitted

×The system is made up of roughly 100 items. No wonder that things that initially seem OK in the so-called dry run may turn out to be obstacles. In the test run, something is built in the workshop and its feasibility then tested. In the second step, an external metalworker is given the prototype of the processing documents and builds something similar. Thus, under certain circumstances, entirely new problems may come to light. The hands-on input of the external practitioner is very important for Forster. It shows what may need to be re-adjusted. This is tedious. It's all about things that you don't always see on the design table and that also don't post any problem as far as craftsmanship in the development workshop is concerned but which would, however, be completely unacceptable when put to practical use. So, by making considerable efforts in the development stage, the company ensures that, in any event, any normal workman can fit very high-quality windows economically using extreme system profiles.

But the responsibility extends further than this. Forster offers regular training. Theory and practice are given equal weight. In addition, technical advisors can be reached by phone at any time whenever concrete assistance is required. Planners and architects can inform themselves in the run-up to tendering, clarify any sticking points, and discuss custom-made products. Besides the free technical documentation, this direct, oral contact (over the phone) is a service that planners and processors appreciate.

The new ‘cleaning windows’ at the von Roll university centre in Bern represent a very special case. Like flat boxes, the slender two-part windows with double leaves are mounted in front of the historic glazing and protect them just like glass cabinets

The new ‘cleaning windows’ at the von Roll university centre in Bern represent a very special case. Like flat boxes, the slender two-part windows with double leaves are mounted in front of the historic glazing and protect them just like glass cabinets

×The new system also has the MINERGIE quality label for energy-efficient construction in Switzerland. Slenderness in steel is a step closer to becoming something normal, although, formally, it is still something out of the ordinary. This also applies to the concealed fittings and the various opening options of a casement, tilt and turn, French casement and bottom-hung window. They are also normal – just not with the minimum facing widths achieved with unico XS (55 mm for French casement windows). This unique characteristic is often decisive when it comes to selecting a single option from all the materials available.

Of course, a window need not be made of steel, but architects appreciate the aforementioned qualities and subtleties that make a steel window so attractive. That's why they are not only used with public projects; nevertheless, a decision in favour of steel always depends on the budget, so, in principle, their use exudes a certain air of exclusivity. Narrow-profiled steel windows are always more than just good windows.