Made for infinity: NEOO by Object Carpet

Historia de la marca de Markus Hieke

Denkendorf, Alemania

10.02.23

Together with circular economy pioneer Niaga, Object Carpet has developed the world's first endless circular carpet – the first step into a circular future...

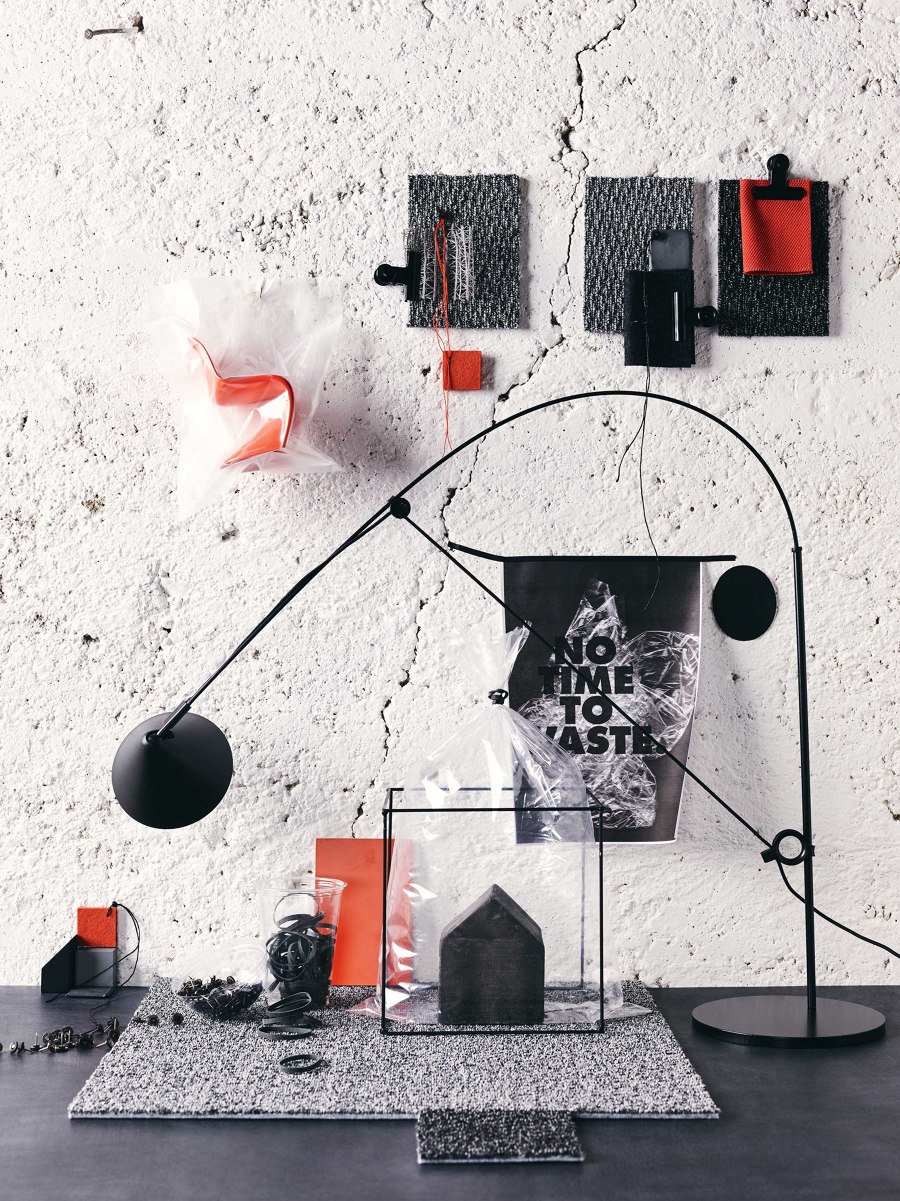

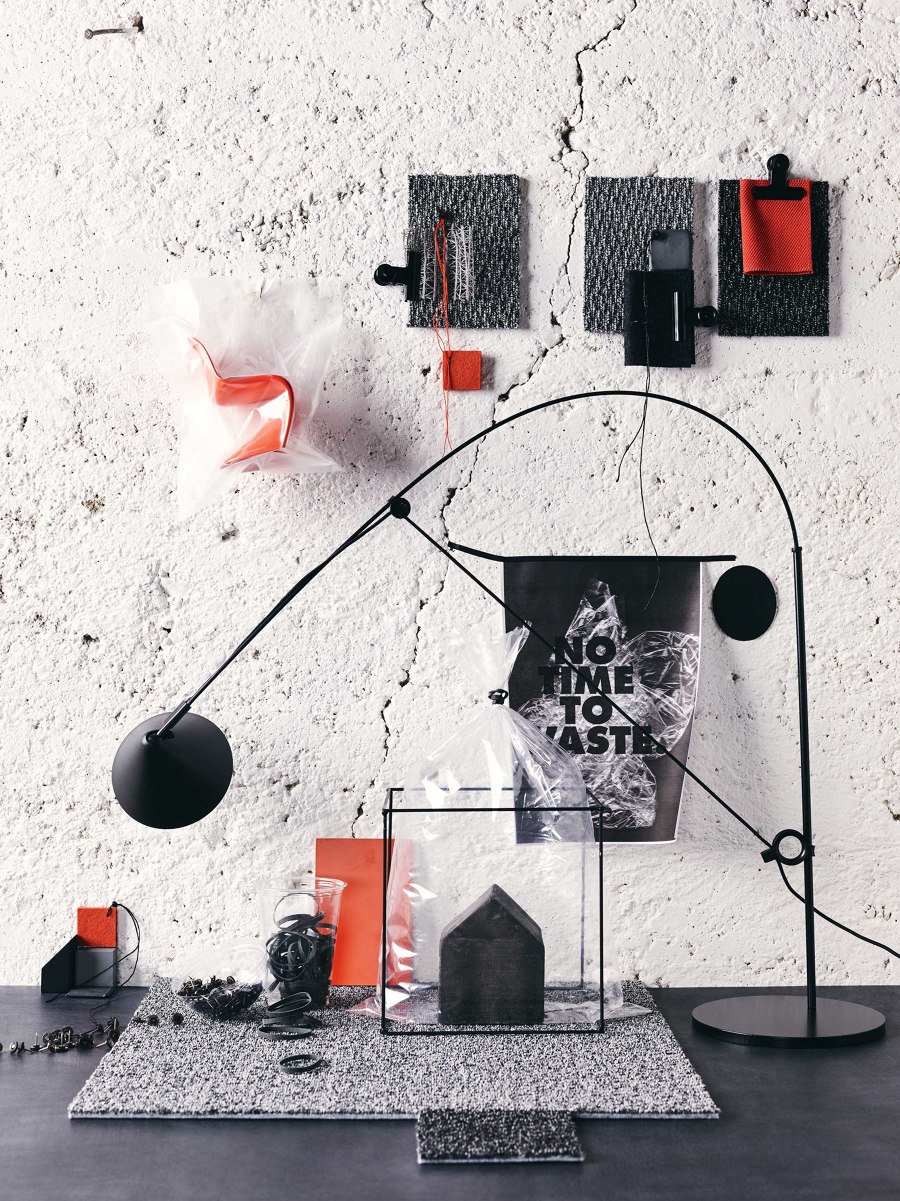

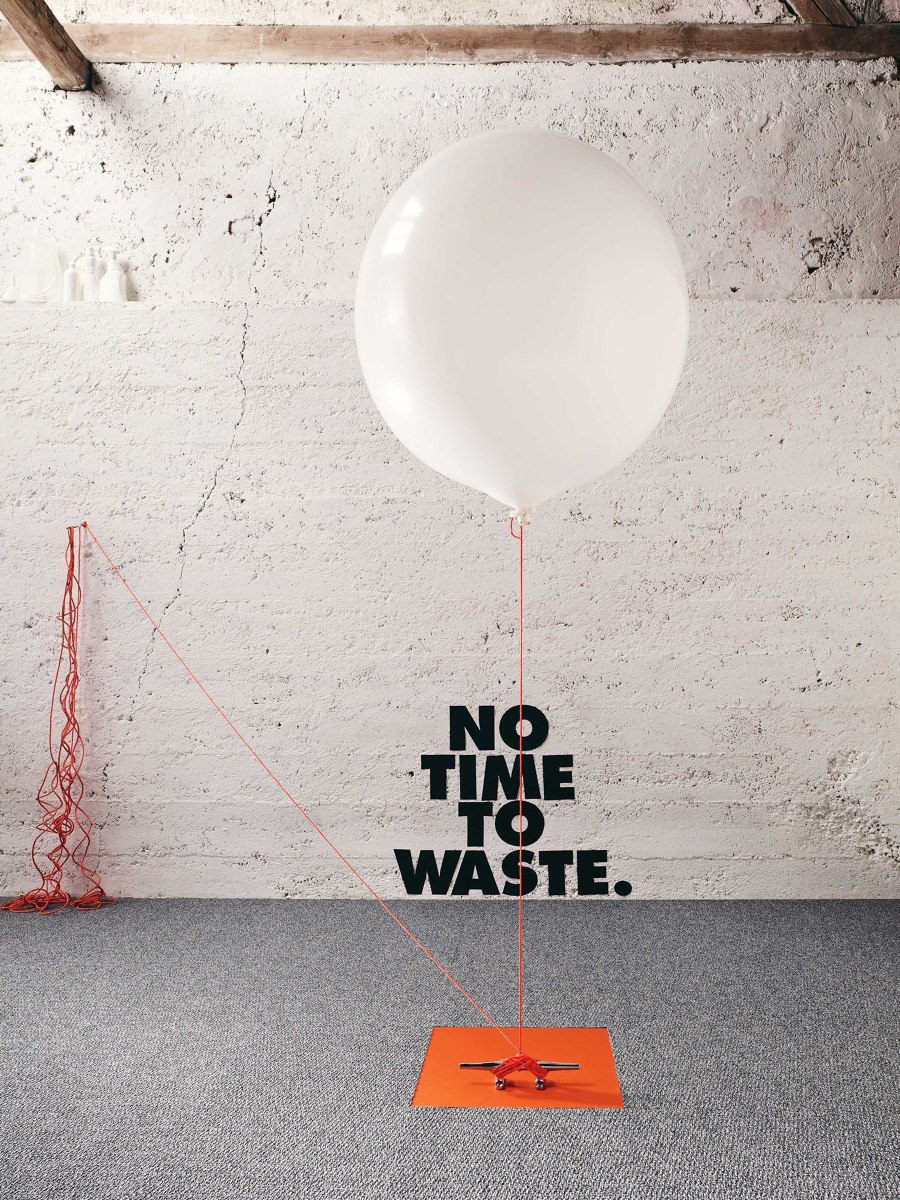

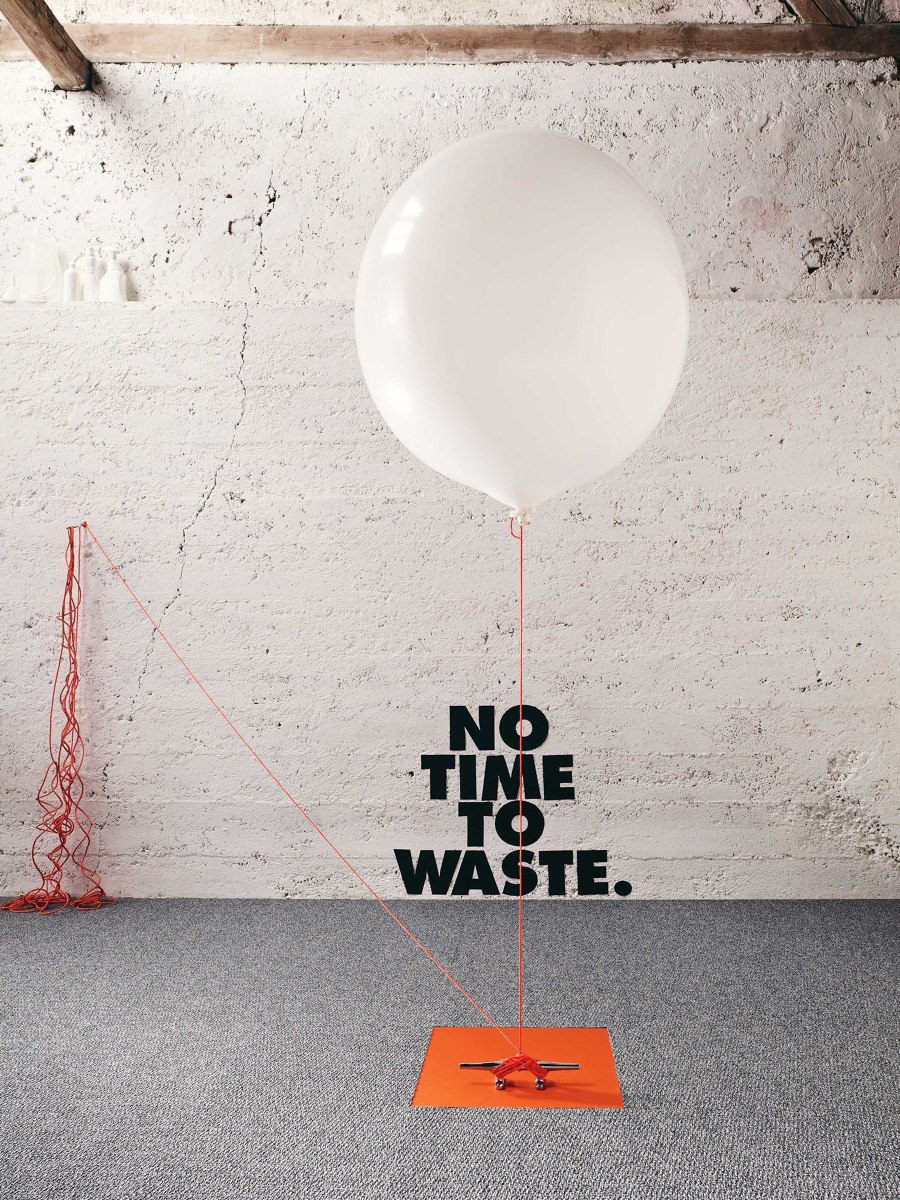

No time to waste: We need to find answers to the pressing issues around climate and raw materials today rather than tomorrow, and of course, recyclable products make a valuable contribution

No time to waste: We need to find answers to the pressing issues around climate and raw materials today rather than tomorrow, and of course, recyclable products make a valuable contribution

×It represents one of the great challenges of our time: how do we best fight climate change and conserve the earth's natural resources? And how can we do it without the feeling that a huge sacrifice in terms of comfort will be necessary? In the face of such enormous threats, It can be easy to feel entirely helpless but localised strategies that go some way to addressing these issues can already be seen in our everyday lives. In Germany, for example, providers of to-go food and drinks are now obliged to offer their customers a reuse option. This means that as soon as a take-away lunch or coffee is sold, consumers must at least have the choice of opting for a reusable container on deposit, one which is properly recycled after multiple uses instead of ending up in a landfill site and too often in the local heating plant after a single use.

With NEOO, Object Carpet has just launched the first 100% circular carpet on the market. It was developed together with Niaga, an innovation company from the Covestro group

With NEOO, Object Carpet has just launched the first 100% circular carpet on the market. It was developed together with Niaga, an innovation company from the Covestro group

×100% polyester = 100% circular

Where the interiors sector is concerned, up to now, there has barely been anything comparable other than, perhaps, rental furniture that can be returned when it is no longer needed. This is changing, however, and with its new offering, NEOO, German carpet manufacturer Object Carpet is making a big statement. Together with Niaga, it has developed a floor covering made of 100% polyester.

‘NEOO is manufactured without fillers and processed with an innovative polyester adhesive. After use, there is therefore no need for material separation’

By comparison, conventional carpeting often contains over 30 different materials – including fillers, chalk, latex or PVC – in order to achieve very specific properties and weights. As a result, these are difficult or impossible to recycle at the end of their life and are eventually sent to the incinerator – just like food packaging.

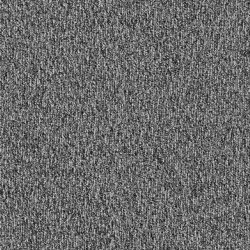

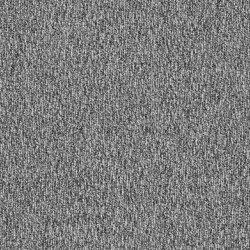

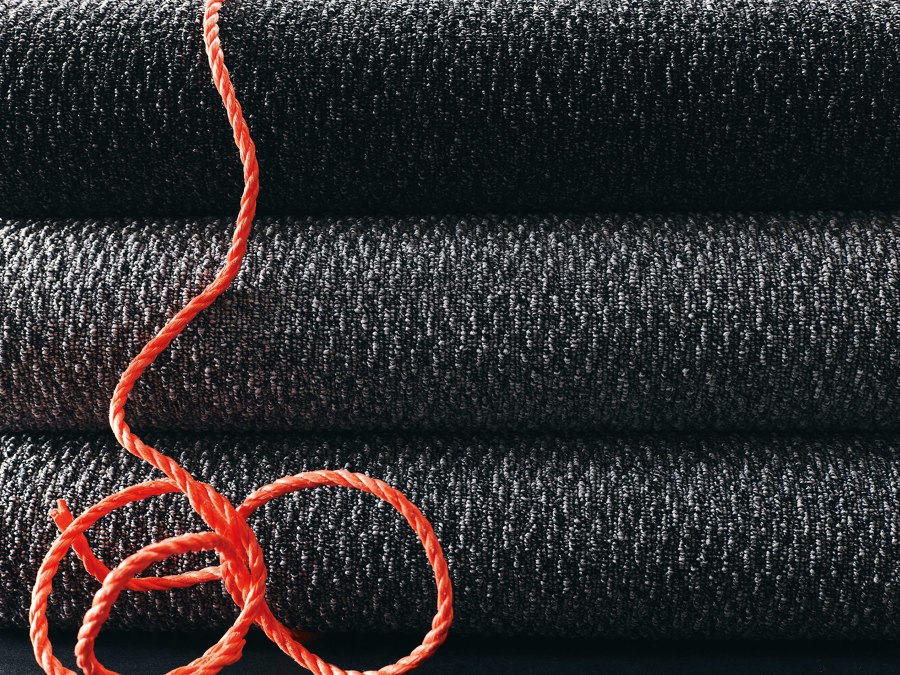

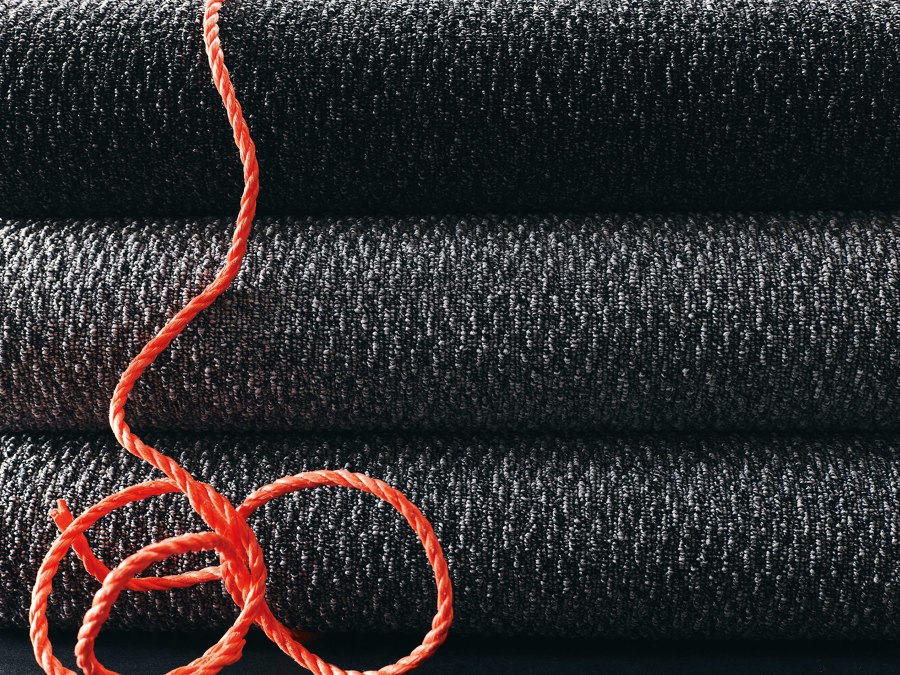

NEOO is available as a 50 x 50 cm carpet tile and as a four-metre-wide roll. Initially, there is a choice of three different shades of grey

NEOO is available as a 50 x 50 cm carpet tile and as a four-metre-wide roll. Initially, there is a choice of three different shades of grey

×In order that this stops happening, Niaga and Object Carpet have fundamentally redeveloped both the coating, backing fabric and adhesive. ‘NEOO is manufactured without fillers and processed with an innovative polyester adhesive. After use, there is therefore no need for material separation,’ explains Lars Engelke, managing director for Production and Development at Object Carpet. Optimised for intensive use, NEOO meets all the requirements of a contract carpet for hotels and offices. Should the carpet one day become obsolete, it can be completely melted down and formed into pellets, which can then be used to make new NEOO carpets, for example – and without any losses in quality. In addition, recycled polyester offers the great advantage of a production process that is four to five times more energy-efficient overall.

Recyclability will be a common thread throughout the Object Carpet range in future. The declared goal is to make all new products circular by 2025

Recyclability will be a common thread throughout the Object Carpet range in future. The declared goal is to make all new products circular by 2025

×Circulation with a system

In this circular process, it is crucial that carpets end up in the right place when they do eventually reach the end of their useful life, and Netherlands-based Niaga again has an important role to play here. Not only significantly involved in the development of the coating system, Niaga's easy-to-understand tag with which all partner products, including mattresses and furniture boards, are marked is also the key to recycling success. The label shows the materials used for each product and a QR code provides information on where the goods can be properly returned for recycling.

Making NEOO's footprint even smaller: New coating equipment at the company's Krefeld location requires neither gas nor water. This creates a saving on energy of 95% compared to conventional production methods

Making NEOO's footprint even smaller: New coating equipment at the company's Krefeld location requires neither gas nor water. This creates a saving on energy of 95% compared to conventional production methods

×Object Carpet is only now delivering the first of its NEOO carpets, so the company, which has its production site in Krefeld, Germany, still has some time before the take-back infrastructure is fully up-and-running. They are also currently thinking about incentives for return – after all, polyester is a raw material that tends to increase in value. The carpet manufacturer is aksi currently collecting installation waste from projects to be able to soon produce the first truly circular flooring products.

‘By 2025, Object Carpet will only be bringing circular floor coverings to the market’

‘We have made it our mission to change the carpet industry sustainably,’ says Daniel Butz, a managing director, before announcing: ‘By 2025, Object Carpet will only be bringing circular floor coverings to the market.’ An ambitious goal, considering that the development of NEOO took a good eight years, before the corresponding fire protection certification as well as the desired acoustic classification could be achieved.

The processing of used polyester is four to five times more energy-efficient than the production of the new raw material. After cleaning, it is melted down and reprocessed before being used again to produce new fibres

The processing of used polyester is four to five times more energy-efficient than the production of the new raw material. After cleaning, it is melted down and reprocessed before being used again to produce new fibres

×NEOO is available both as a 50 x 50-centimetre carpet tile and in four-metre wide strips. In terms of colour, it is initially limited to three shades of grey, which are produced from three yarns dyed in an environmentally friendly solution-dyed process in appropriate mixing ratios. The compositions provide the carpets with exciting contrasts as well as impressive characteristics in terms of extreme durability, dirt resistance and easy maintenance. The consistent limitation of the colour range also helps to keep the ecological footprint low. This means that the manufacturer does not have to keep an excessively large quantity of different yarn colours in stock if, in the end, grey shades are generally ordered. The NEOO floors act like a blank canvas on which coloured accents or pieces of furniture with natural textures really come into their own.

© Architonic

Head to the Architonic Magazine for more insights on the latest products, trends and practices in architecture and design.