From the Norm To the Individual Solution: SUBLIDOT®

SUBLIDOT®: Because the unique laser system is able to refine any material particularly gently.

noviembre 27, 2018 | 11:00 pm CUT

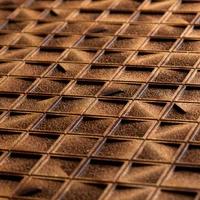

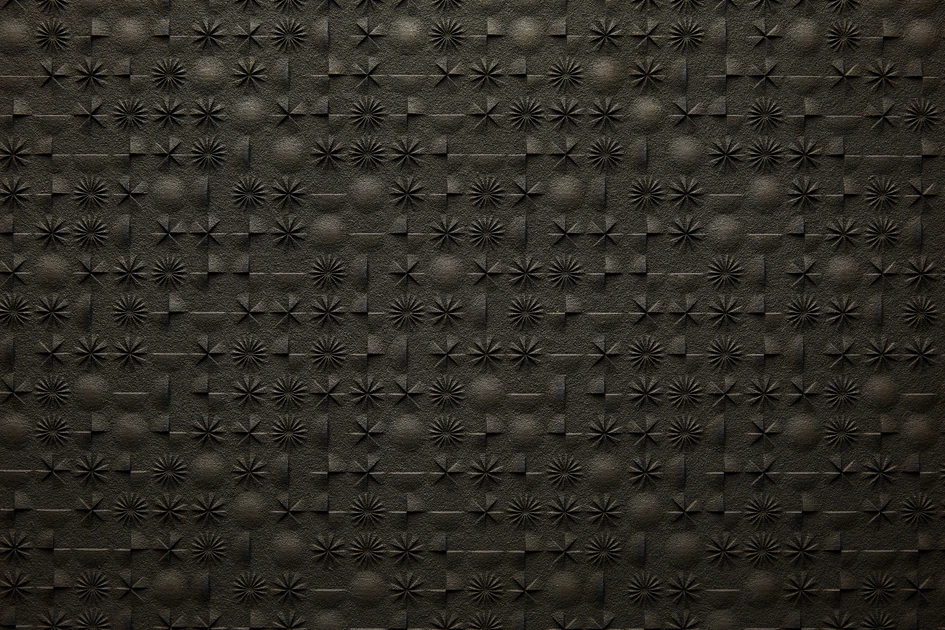

Laser sublimation of solid wood, veneer or any other organic materials is present and tool of the future. Exact edges, even with complicated object shapes or sizes, even in uneven form with consistent quality. Creativity acquires new dimensions.

The sublidot Laser System is geared to the needs of interior architecture, furniture construction and semi-finished products. Nowadays, in order to produce in a high-quality and efficient manner, besides precise workmanship, a great amount of high-tech is necessary. In this way, our laser systems also produce individual customer designs – for fronts used in kitchens, bathrooms, on cupboards, as well as furniture elements or facings for walls and ceilings.

Parts are processed in different plate formats. The maximum machining dimension for the current machine park is 310x210cm. The applied structures can be continued across components and over edges. If required, sublimated surfaces and components can be equipped with advanced, sound-absorbing properties through the prior micro-perforation of the base material. Depending on the panel material and the subsequent surface sealing, the scope of application ranges from furniture to façade construction. The sublimated surfaces can be purchased and delivered.

Galería de proyectos