À propos de Richlite Company

EN SAVOIR PLUS SUR RICHLITE COMPANY

Established in 1943, Richlite Company, based in Tacoma, Washington, started producing natural fibre composites for aerospace and industrial markets in the late 1950’s. The material was used for tooling purposes by Boeing and later adopted by the marine industry as a boat building material.

Richlite has been used for food prep surfaces in commercial kitchens since the 1960’s. Sales on the commercial food side of the business continue to flourish due to the surface’s sanitary properties and low maintenance requirements.

In the 1990’s Richlite introduced a similarly produced product called Skatelite®, a ramp surface material used in the world’s top skateparks, extreme sports events and by the top professional BMX riders and skateboarders on their personal ramps.

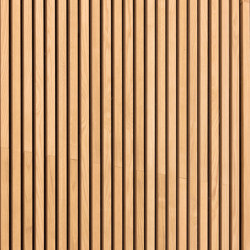

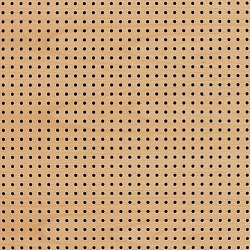

Today Richlite Paper Composite Surfaces are used in a wide range of applications including; Desktops, External & Internal Cladding, Furniture, Guitar Fret Boards, Marine, Phone Cases, Retail Surfaces, Skate Ramps, Table tops, Theatre & Stage Flooring, Worktops and many more.

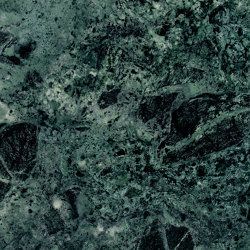

Attractive, versatile, durable: Richlite products look great and performs well under the toughest conditions whether used for industrial, recreational or culinary purposes.

Sustainability

For 70 years Richlite Company has been devoted to producing a quality product that is aware of the environment it is produced in. Our company will always be committed to improving our sustainable practices while never sacrificing quality.

WASTE-TO-ENERGY (WE™) TECHNOLOGY

During manufacturing, the waste from processing our raw materials is converted into energy used to sustain our heating system. This occurs during the paper saturating process where we now use 83% less fuel. Our innovative WE™ manufacturing design captures solvents left over from the manufacturing process and recycles it back as energy into our heating system.

CARBON FOOTPRINT

Richlite began tracking emissions in 2005 using the Greenhouse Gas Protocol (GHG Protocol), which was developed through a partnership between the World Resources Institute and the World Business Council for Sustainable Development. Richlite has made great strides in reducing carbon emissions, however, we continuously review our three different scopes of emissions.

SUSTAINABLE MATERIALS

All Richlite materials are made either with Post-Consumer Recycled Paper or FSC® Certified. FSC® is a global non-profit organisation devoted to encouraging the responsible management of the world’s forests. FSC® sets high standards that ensure forestry is practiced in an environmentally responsible, socially beneficial, and economically viable manner.

INDOOR AIR QUALITY

Richlite’s products are non-off-gassing, are GREENGUARD Indoor Air Quality Certified®, and meet the criteria for GREENGUARD Children & Schools Certification. The GREENGUARD Certification program recognises interior building materials and products that meet the most stringent chemical emissions standards deemed safe and appropriate for use in residential and commercial buildings, including educational (daycare and K-12) environments.

GEI is an industry-independent, non-profit organization that oversees the GREENGUARD Certification Program. As an ANSI Authorised Standards Developer, GEI establishes acceptable indoor air standards for indoor products, environments, and buildings. GEI’s mission is to improve public health and quality of life through programs that improve indoor air.

LEED®

Richlite’s sustainable manufacturing and LEED® credit information:

MR Credit 3: Materials Reuse

Durability is a primary attribute of Richlite. Richlite will last a lifetime – whether it stays in its original installation or is re-fabricated into another project. Richlite can be easily refinished to its original appearance.

MR Credit 4: Recycled Content

Richlite r50 product contains 50% of fibres from post consumer waste. Richlite r100 product contains 100% of fibres from post consumer waste and is also FSC® Certified.

MR Credit 5: Regional Materials

Richlite products are manufactured in Tacoma, Washington. Richlite’s r50 and r100 paper suppliers and Richlite’s resin supplier are within 200 miles of the manufacturing plant.

MR Credit 6: Rapidly Renewable Materials

Richlite FSC® Certified products are composed of 30% Eucalyptus fibres. Richlite FSC® Certified products can be applied to both MR Credit 6 (rapidly renewable materials) and MR Credit 7 (certified wood) below.

MR Credit 7: Certified Wood

Use a Richlite FSC® Certified product and apply it to two points, not just one. 30% of Richlite’s FSC® Certified product uses eucalyptus fibres (a rapidly renewable material under MR Credit 6).

IEQ Credit 4.4: Low-Emitting Materials: Composite Wood & Agrifiber Products

Richlite contains no urea formaldehyde. In addition, all Richlite products are GREENGUARD Certified for Children & Schools – the highest rating GREENGUARD supplies. Also note that 100% of the VOC’s created during manufacturing are destroyed.

ID Credit 1: Innovation in Design

Richlite has seen its material used in some very unique and sustainable ways in building projects. Richlite will provide the form… you provide the function.

Established in 1943, Richlite Company, based in Tacoma, Washington, started producing natural fibre composites for aerospace and industrial markets in the late 1950’s. The material was used for tooling purposes by Boeing and later adopted by the marine industry as a boat building material.

Richlite has been used for food prep surfaces in commercial kitchens since the 1960’s. Sales on the commercial food side of the business continue to flourish due to the surface’s sanitary properties and low maintenance requirements.

In the 1990’s Richlite introduced a similarly produced product called Skatelite®, a ramp surface material used in the world’s top skateparks, extreme sports events and by the top professional BMX riders and skateboarders on their personal ramps.

Today Richlite Paper Composite Surfaces are used in a wide range of applications including; Desktops, External & Internal Cladding, Furniture, Guitar Fret Boards, Marine, Phone Cases, Retail Surfaces, Skate Ramps, Table tops, Theatre & Stage Flooring, Worktops and many more.

Attractive, versatile, durable: Richlite products look great and performs well under the toughest conditions whether used for industrial, recreational or culinary purposes.

Sustainability

For 70 years Richlite Company has been devoted to producing a quality product that is aware of the environment it is produced in. Our company will always be committed to improving our sustainable practices while never sacrificing quality.

WASTE-TO-ENERGY (WE™) TECHNOLOGY

During manufacturing, the waste from processing our raw materials is converted into energy used to sustain our heating system. This occurs during the paper saturating process where we now use 83% less fuel. Our innovative WE™ manufacturing design captures solvents left over from the manufacturing process and recycles it back as energy into our heating system.

CARBON FOOTPRINT

Richlite began tracking emissions in 2005 using the Greenhouse Gas Protocol (GHG Protocol), which was developed through a partnership between the World Resources Institute and the World Business Council for Sustainable Development. Richlite has made great strides in reducing carbon emissions, however, we continuously review our three different scopes of emissions.

SUSTAINABLE MATERIALS

All Richlite materials are made either with Post-Consumer Recycled Paper or FSC® Certified. FSC® is a global non-profit organisation devoted to encouraging the responsible management of the world’s forests. FSC® sets high standards that ensure forestry is practiced in an environmentally responsible, socially beneficial, and economically viable manner.

INDOOR AIR QUALITY

Richlite’s products are non-off-gassing, are GREENGUARD Indoor Air Quality Certified®, and meet the criteria for GREENGUARD Children & Schools Certification. The GREENGUARD Certification program recognises interior building materials and products that meet the most stringent chemical emissions standards deemed safe and appropriate for use in residential and commercial buildings, including educational (daycare and K-12) environments.

GEI is an industry-independent, non-profit organization that oversees the GREENGUARD Certification Program. As an ANSI Authorised Standards Developer, GEI establishes acceptable indoor air standards for indoor products, environments, and buildings. GEI’s mission is to improve public health and quality of life through programs that improve indoor air.

LEED®

Richlite’s sustainable manufacturing and LEED® credit information:

MR Credit 3: Materials Reuse

Durability is a primary attribute of Richlite. Richlite will last a lifetime – whether it stays in its original installation or is re-fabricated into another project. Richlite can be easily refinished to its original appearance.

MR Credit 4: Recycled Content

Richlite r50 product contains 50% of fibres from post consumer waste. Richlite r100 product contains 100% of fibres from post consumer waste and is also FSC® Certified.

MR Credit 5: Regional Materials

Richlite products are manufactured in Tacoma, Washington. Richlite’s r50 and r100 paper suppliers and Richlite’s resin supplier are within 200 miles of the manufacturing plant.

MR Credit 6: Rapidly Renewable Materials

Richlite FSC® Certified products are composed of 30% Eucalyptus fibres. Richlite FSC® Certified products can be applied to both MR Credit 6 (rapidly renewable materials) and MR Credit 7 (certified wood) below.

MR Credit 7: Certified Wood

Use a Richlite FSC® Certified product and apply it to two points, not just one. 30% of Richlite’s FSC® Certified product uses eucalyptus fibres (a rapidly renewable material under MR Credit 6).

IEQ Credit 4.4: Low-Emitting Materials: Composite Wood & Agrifiber Products

Richlite contains no urea formaldehyde. In addition, all Richlite products are GREENGUARD Certified for Children & Schools – the highest rating GREENGUARD supplies. Also note that 100% of the VOC’s created during manufacturing are destroyed.

ID Credit 1: Innovation in Design

Richlite has seen its material used in some very unique and sustainable ways in building projects. Richlite will provide the form… you provide the function.

EN SAVOIR PLUS SUR RICHLITE COMPANY