Reproduction of the Reproduction of the Reproduction...

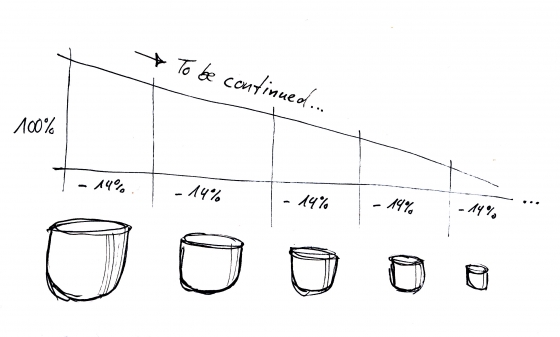

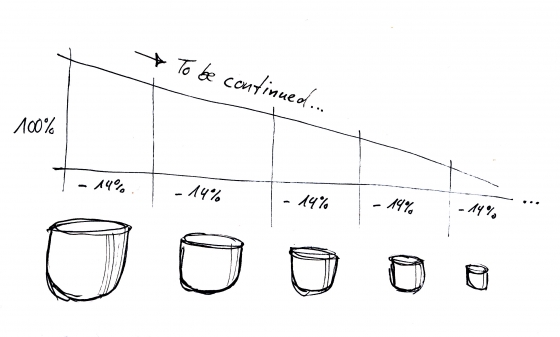

Shortly after the establishment of the Meißner manufacturing fi rm, their modellers copied Chinese products, creating negative mouldings of the forms or reproducing them in 1:1 standards. The replications that resulted could not to be distinguished from the Chinese originals almost up to one difference: they were smaller, since porcelain shrinks in the fire. The copy is reliant on the quality of the material for its character. There existed only a few pieces from the early days of the Meißner porcelain manufacturing times that have this “beauty fault”. They testify in my eyes to the poetic manner of the apparent “malice” that reproductive technology may have. These pieces from the early period of the Meißner manufacturers were a point of departure and inspiration for the design entitled “14%”. What came into being was a cover light with 9 lampshades made of porcelain. The porcelain screens were the result of a 5 times repeated reproduction process. Every lamp bonnet is a reproduction of the previous one, which is in turn a copy of that preceding bonnet. In such a sequence the bonnets become continually 14% smaller with each phase.

Constantly a soft 14%...

For the production of these ever smaller screens, a material aspect to porcelain was consciously used: in the glaze fi ring at 1.400°, the shards melt to a white and very hard porcelain. In so doing, it shrinks by 14% of its original size. By glazing the porcelain it fades gently away at the edge and gets a “gently-washed” surface. Further, soft porcelain shards can contort in the fi re. This feature is an unhappy one for the porcelain industry because it can lead to high rate of porcelain rejects, especially with complex shapes. Regarding the ceiling light, 14% is every screen that is a cast of the preceding larger screen and was itself a cast model for the following smaller screen. Besides the change rate of 14% whereby each screen is smaller than its predecessor, there is with every reproduction a resulting loss of contour as well as a gain in contortion of the form. Thus the first and therefore largest lampshade is still sharp and exact in its shaping. However, the fi fth cast looks gently washed and contains no contour. The material characteristic of the porcelain lamp gains by 14%. The otherwise disliked attribute of the porcelain in the fire, when it pulls and deforms, was challenged with the change in 14%; generates an exciting almost organically looking alteration in the porcelain screens of the light. Nine screens were created by means of reproduction.

A gypsum form was provided by the prototype. With this the porcelain shards were created and burnt afterwards. The burnt shard provided a gypsum form; porcelain shards were poured and burnt … this trial was run through 5 times in succession. As of the 2nd reproduction, two casts were made using gypsum since several casts of one form are quite different. The related forms are not absolutely similar. 14% is a light that is full of copies and originals. Our perceptions of the differences fl ow between these elements.