Material Tendencies: Ross Lovegrove

Texte par Anita Hackethal

Berlin, Allemagne

26.05.15

The design works of Ross Lovegrove maintain a trinity between technology, materials science and intelligent organic forms and structures that nature has evolved. Lovegrove likes to push the boundaries of rapidly developing technologies and enjoys the digital age of the 21st century. His passion for form in motion and the embodiment of lightness is clearly reflected in his visionary work.

Ross Lovegrove - Photo © Architonic / Anita Hackethal

Architonic met the British Designer in Milan and asked him what first comes to mind when confronted with the decision to work with ONE material only for the next three years. What would it be?

Ross Lovegrove: 'Silk in a very advanced composite. It would be like a bi-sex material: natural silk combined with a man-made, really advanced composite. So something natural as a composite and something artificial as a composite. As a textile, that could inform anything that goes from soft to semi-soft to semi-rigid to rigid... Something that would traverse all of that bandwidth.'

… and what material could you immediately reject (also within the time frame of three years)?

Lovegrove: 'My reflex is to say concrete because of the weight. It’s not about the concrete, it’s about the weight itself. So I would promote anything light, whatever that is. Concrete was invented by the Romans, and I think we need to move on a little bit.'

---

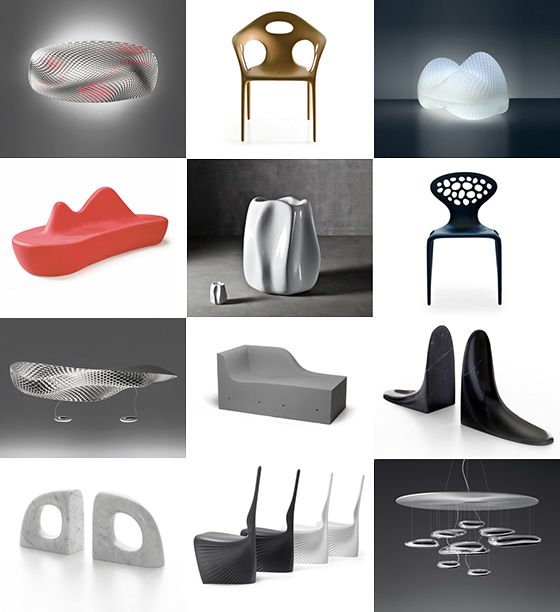

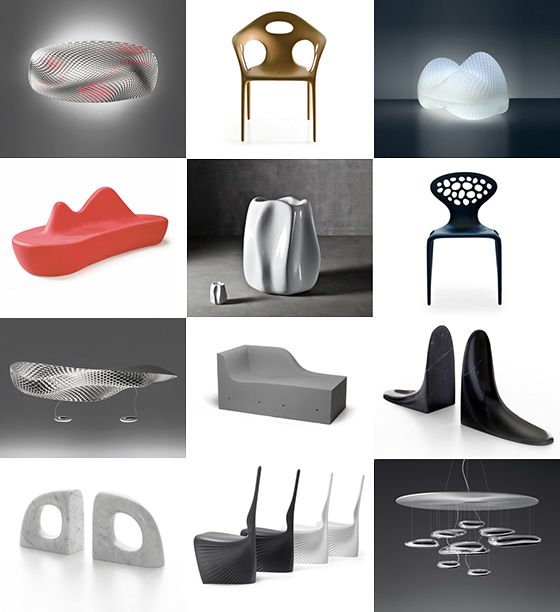

Here is a selection of further design works by Ross Lovegrove, starting with his most recent projects:

Ilabo 3D-printed shoe for United Nude (limited edition), 2015

These 3D-printed ladies high heels are part of the collaborative exhibition "Re-Inventing Shoes" by United Nude and 3D Systems that was presented this month during New York Design Week, after its first launch in Milan. Using the highest quality of 3D-printing – Selective Laser Sintering (SLS), an additive manufacturing technique – United Nude have discovered a way to combine harder and softer 3D-printed parts for creating fully functioning shoes made of a hard nylon and all-new soft rubber material.

Lovegrove: 'We have entered a second renaissance that is like a spaceship moving away from an analogue Earth into a nebula of extraordinary abstract beauty that will lift our psyche to new limits of speculation and biomimetic understanding ... closer in fact to our true instinctive view of a non-linear world.'

The complex tridimensional polygon mesh of the "Ilabo" shoe provides a "watertight geometry" whereby nothing is extraneous, either in material volume or functional characteristic.

'The freedom afforded by the unbridled free-form sculpting of advanced 3D-printing is totally invigorating and emotionally stimulating,' explains Lovegrove. 'I have used this project to establish a moment where physical innovation in materials density and layered matrix node structuring are coalesced to enhance the sensuality of the female form whilst remaining clearly technological … Ultimately the shoe has been truncated to extending the perception of verticality and in doing so eliminate weight and mass, which for me is a symbol of decadence.'

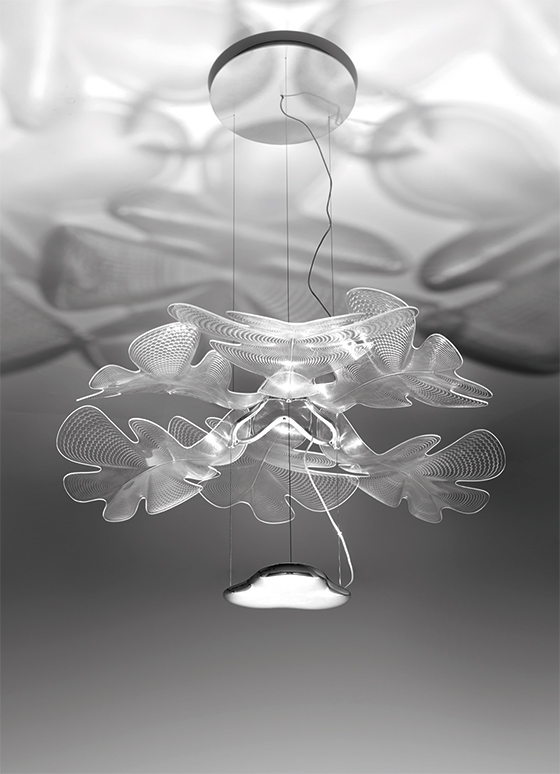

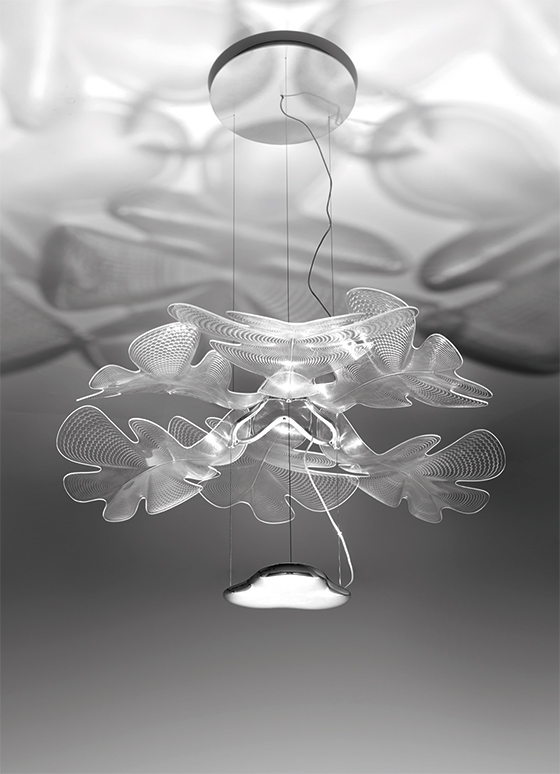

Chlorophilia for Artemide (techno-polymer / polished aluminium), 2015

Chlorophilia is a highly scenic, yet light suspension appliance that reflects Lovegrove’s signature approach to organic and fluid form. Containing a COB LED, the central cast aluminium body emits indirect light, which is filtered and refracted by clear, gently wavy, leaf-shaped surfaces made of moulded techno-polymer. When switched on, Chlorophilia unveils a contrast of delicate shades generating a scenic effect on the ceiling.

'It is an installation of optical leaves conceived as a fusion of natural and artificial geometries. The light becomes interactive through caustic projection onto the ceiling, creating a delicate and feminine ethereal space expanding effect.'

Diatom 100% aluminium chair (indoor + outdoor) for Moroso, 2014

Entirely computer generated, this lightweight vertical stacking chair responds to the logistics of contemporary aluminium pressing technology and its origins in the automotive industry. As the word implies, "diatom" has been generated by the beauty and logic of natural lightweight structures.

'My path in the designing of chairs is to embrace technologies that open up new possibilities and with this a commitment to exploring the moment where industrial investment can result in products that are aesthetically uplifting, long-lasting and respectful of environmental issues, yet economically accessible from a cultured design house to a wider audience.'

Foliates 3D-printed 18ct gold rings for Louisa Guinness Gallery, 2013

'The term “Foliates” is derived from the botanical world of plants. It relates to leaves and leaf structures, their highly evolved shapes that are there to capture sunlight and rain. These rings appear as if the very last virgin leaves of a tree or plant have unfurled from one’s hand… They sit lightly, exploring the dynamics of space and the digital realm converging organic design with the nature of naturalness that underlines my life’s commitment to sourcing the trinity that can exist so succinctly when technology, materials and form converge in the advanced times in which we live.'

MOOT carbon-fibre chair for Established&Sons (limited edition), 2013

The MOOT chair is another technical tour de force that reflects Lovegrove's continuing fascination for lightweight, fluid forms in motion and high-end technology. The British designer has chosen to use carbon fibre – a material that has been pioneered by aircraft manufacturers and Formula 1 car builders. The complex curvature, with a cantilevered seat turning toward the back of the chair, could not be achieved using any other material and gives it strength and stability.

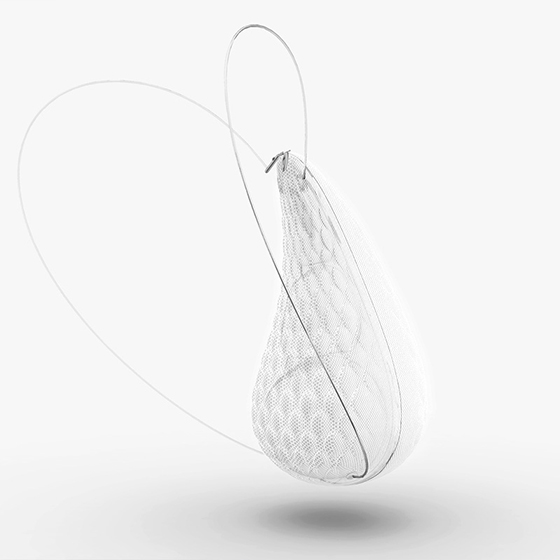

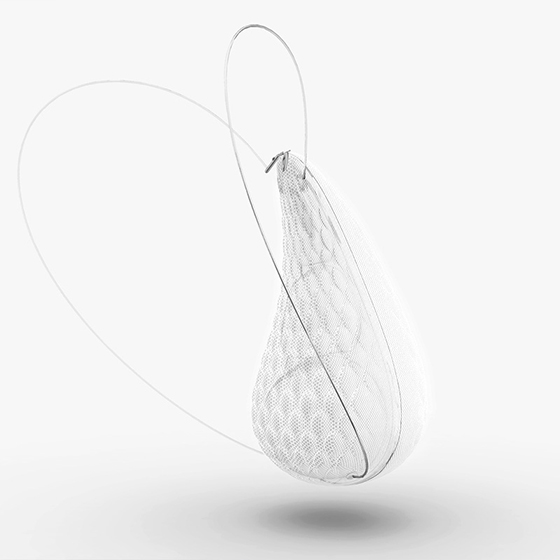

Seed of Love (Triaxial Woven Fabric with MELSET™ fibre, limited edition), 2009

'Seed of Love,' explains Lovegrove, 'is a seed of thought manifested as a three-dimensional object for the carriage of feminine seductive objects into marriage.'

The wedding accessory is made of Triaxial Woven Fabric (TWF) that uses three yarn ends woven at 60 angles. In contrast to conventional, biaxial woven fabric with two yarn ends interwoven at 90 angles, this extremely lightweight fabric can provide a greater stiffness.

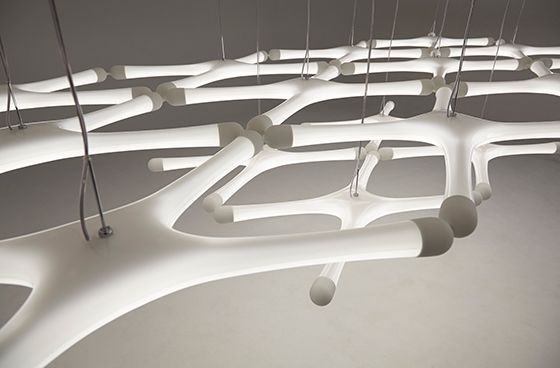

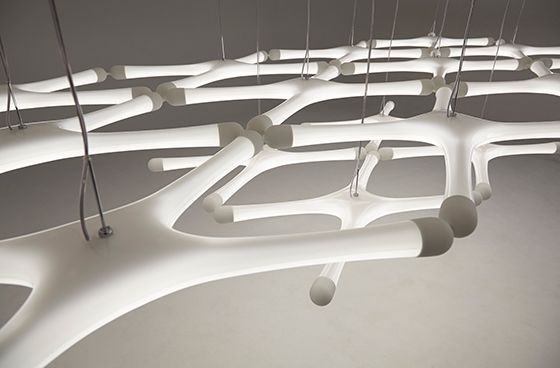

System X light modules (plastic, aluminium) for Yamagiwa, 2005

The structure of "System X" was designed to use minimum suspension wire and power-supply cable. The plastic light modules interconnect to form a grid matrix and they can also be built into a circular pattern, using either five or eight units.

Ridon portrays a rider and motorcycle at speed, morphed into one shape. Expressed in an exaggerated way, the art piece is made of carbon fibre, a lightweight, high-strength material that stands for speed.

Made from the same material and manufacturing technology as most high-volume mineral water bottles , this packaging product set out to communicate the universal importance and value of pure spring water by its intrinsic form and optical beauty.

....

Look out for more Material Tendencies reports. We’ve captured insights from renowned designers we met recently in Milan, and we’re delighted to be able to share them with you in the forthcoming weeks, as part of our ongoing Architonic Trend Analysis series.

....