Materialica

Texte par Christiane Sauer

Berlin, Allemagne

28.02.08

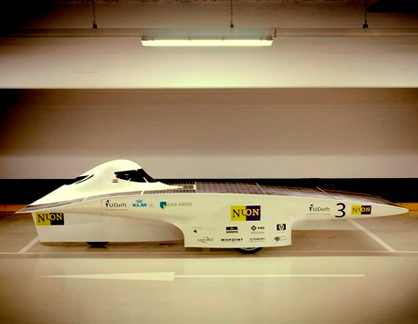

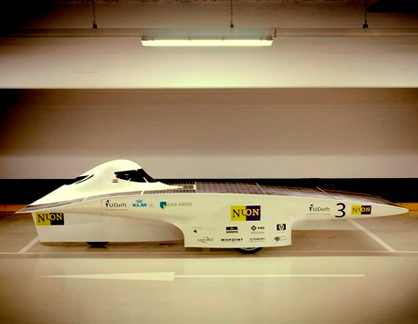

The tenth MATERIALICA in Munich focused specifically on design. For the fifth time the fair presented the Materialica Design + Technology Award to outstanding and innovative performance in the fields of design or engineering.

The tenth MATERIALICA in Munich focused specifically on design. For the fifth time the fair presented the Materialica Design + Technology Award to outstanding and innovative performance in the fields of design or engineering. The aim of the annual competition is to highlight the relevance of production materials to applications oriented towards industrial design, and to bring together the producers of materials, designers, and the manufacturers of finished products. A total of 19 products received awards in the categories of 'Material', 'Surface Finish', 'Product' and 'Student'. Here are some of the most interesting products which received awards.

One of the prize winners in the 'Material' category is Turane – a composite material which combines the properties of epoxy resin and polyurethane. The material has excellent mechanical properties, is heat-resistant and represents an interesting alternative to epoxy resins with regard to better environmental sustainability and low-cost processing. The manufacturer is Switzerland's DSM Composite Resins AG.

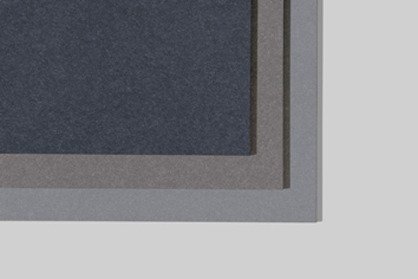

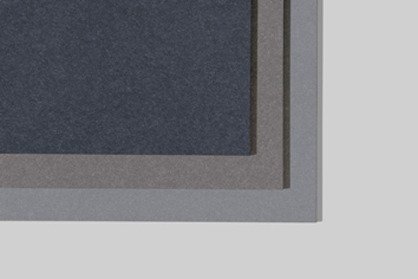

Fibre cement facade panels with a highly consistent surface colour can be generated by the rolling and casting technology developed by Eternit. At the same time the specific material properties of the solid coloured fibre cement panels are highlighted. Colour finishes in 42 different shades are available, starting with gray and anthracite.

Eternit's fibre-concrete: from now on also coloured

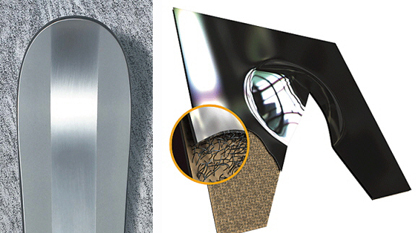

Hybrix from the firm of Lamera is a super-light form of stainless steel sheeting. This micro-sandwich consists of air and two outer layers, which are held together by millions of microscopically small steel fibres. The unique fibre structure makes the material robust and light (1.5-3.9 kg/m2). This means it has half the weight of conventional stainless steel sheeting. It can be shaped in hydroformers or metal presses and can be bent or curved.

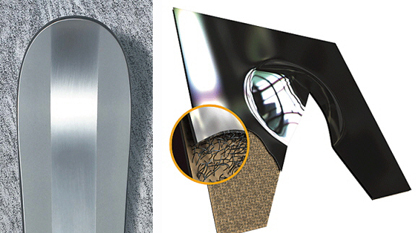

In the 'Product' category an entirely new material is creating a stir: carbon-fibre reinforced natural stone. With a special surface coating made of carbon-fibre laminate, the firm of Techno Carbon Technologies has succeeded in making natural stone flexible and elastic. The Swiss ski manufacturer Zai has taken advantage of these new properties of stone and developed the first ski with a core made of Bündner gneiss. The advantages are that stone absorbs the vibration of the skis, which provides it with extremely smooth running characteristics and adhesion. The power required remains minimal and at the same time the ski holds its tracks as if on rails.

The ski by Zai consists of carbon-fibre reinforced natural stone by Techno Carbon Technologies

A technically advanced design is the GM Railing Plan made entirely out of glass by Glas Marte GmbH. All the aluminium connecting sections are integrated into the railing and after assembly they give the impression of a pane of glass which is held in place by invisible means. GM RAILING Plan consists of two main components: the sub-frame and the outer structure. The separation of the connecting sections means that the sub-frame does not need to be dismantled for service purposes.

An award was made to Inglas Deko Wilder Wein for its special decorative properties. This , laminated safety glass with integrated decorative material consists of two thermally pre-stressed sheets of glass, with processed tendrils of Virginia creeper in the bonding area. In order to create the effect of space (3D effect) the tendrils of creeper are positioned at different levels of the bonding area. Typical applications for Inglas Deko Wilder Wein are shower partitions, partition walls, table tops and furniture sections.

In the 'Student' category a prize went to a hybrid item of furniture which was designed at the department led by Prof. Achim Menges at the Offenbach college of design. The Lounge Landscape can be used for sitting or reclining, and is characterised by two innovative aspects: one is a new type of composite material made of a three-dimensional knitted nylon fabric in a fibre-glass sandwich, providing a combination of stability and low weight. The other aspect is the specific geometry of the surface area, which makes it possible to create an entire family of individual and different objects, all of them produced from the same 'parent' mould.

The products which have been presented are distinguished by an intelligent interplay of material, design and technology. What is noticeable is that new synthetic compounds and composite materials containing a number of different components are becoming prominent, because the targeted manipulation of the individual building blocks enables them to be adapted ideally to the individual application or the desired look.