MaterialVision

Texte par Christiane Sauer

Berlin, Allemagne

25.02.08

Innovative materials inspire designers and architects to create ever new products and applications. This was demonstrated at the end of 2007, when the latest developments in the field of new production and surfacing materials were presented at two leading materials exhibitions: Materialica in Munich and Material Vision in Frankfurt/Main.

Innovative materials inspire designers and architects to create ever new products and applications. This was demonstrated at the end of 2007, when the latest developments in the field of new production and surfacing materials were presented at two leading materials exhibitions: Materialica in Munich and Material Vision in Frankfurt / Main.

As a platform for materials in product development, design and architecture, Material Vision this year awarded the Design Plus prize to 30 products. These were selected on the criteria of innovative material, successful design and intelligent functionality.

Among the prize-winning products, for example, was THE KETTLE (Heat Concepts, IDEO), a kettle in the form of a carafe, which doesn't need a handle because of its heat-resistant Ultrason material. This high-tech plastic developed by BASF is suitable for use at high temperatures of up to 220 °C. This means that the outside of the kettle can be touched at any time – even when the contents are hot – without the risk of a burn, while the transparent container means that the water can be seen bubbling as it boils.

An award also went to the Lyn lamp by Christophe Marchand Design. The jury was especially impressed by the successful combination of high-tech and charm, which is expressed by the textile lampshade which has been produced by the latest knitting technology. This knitted lampshade consists of a heat-resistant fabric which reflects the light, ensuring that it is not just diffused outwards but also radiates inwards.

The ZipLiege, a product manufactured in the ZipShape technology by designtoproduction, Zürich, impressed the jury with the simple production methods on which it is based. The ZipShape process makes it possible to manufacture curved surfaces without a profile gauge. The system uses two individually toothed plates which interlock in such a way that they only fit in the required curve, with the geometry of the teeth determining the curve of the plate.

The form of the toothing is calculated on the basis of a computer drawing and produced automatically. In addition, this technology has recently received the 2008 iF Material Award.

The Maplex wood material (well Ausstellungssytem GmbH) is characterised by sustainability and a wide range of applications. This material, which is made entirely out of cellulose, can be shaped permanently like metal and can be cut, drilled, formed or punched. The material, which is also described as 'sheet wood', is fully degradable. Maplex enables permanent shapes to be produced in the same way as sheet steel is processed. With its flat characteristics the material can be processed with CNC machinery and is therefore ideally suited to series production of products such as chairs, shelves and decorative objects. Its metal-like properties also make the material suitable for automobile production.

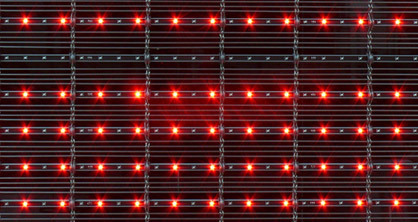

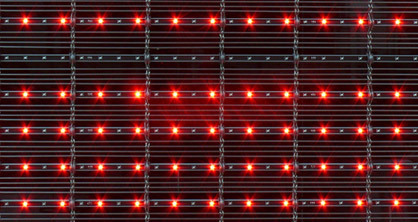

A further award went to Mediamesh, a patented system for turning large facades into media surfaces which has been developed by ag4 media facade GmbH and GKD - Gebr. Kufferath AG. In its basic concept Mediamesh is a stainless steel mesh with LED profiles woven into it, behind which the media controls are positioned. The LEDs reproduce the image on the facade, enabling a wide spectrum of graphics, texts and videos.

Mediamesh by ag4 media facade GmbH and GKD - Gebr. Kufferath AG