The Making of Architonic Concept Space II

Texte par Nora Schmidt

Berlin, Allemagne

20.01.09

The vision behind the Architonic Concept Spaces is to bring together innovative designers on the one hand with the latest technologies, materials and producers on the other.

The vision behind the Architonic Concept Spaces is to bring together innovative designers on the one hand with the latest technologies, materials and producers on the other. This year the series is being continued by the Swiss architects Gramazio & Kohler, in cooperation with Swisspor (materials sponsor) and AGF AG for liquid sealing (processing partner - PU coating).

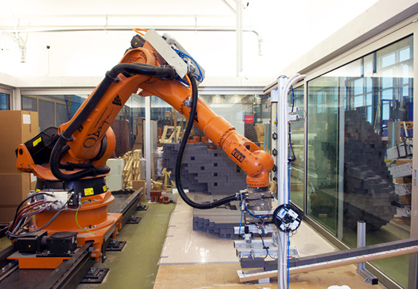

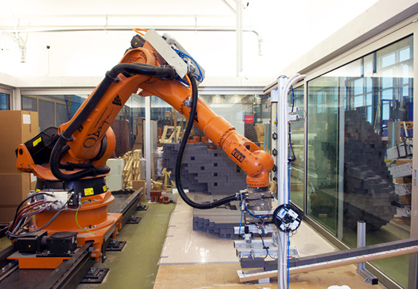

The department of architecture and digital production at the ETH Zurich, which has been led by Fabio Gramazio and Matthias Kohler since 2005, specialises in the concept of 'digital materiality', the linking of digital data with material and the resulting findings for design and production processes in architecture. The aim is to design digitally generated structural sections in original size using computer-controlled tools and robots in an application-specific way. This doesn't just improve efficiency but also creates greater design freedom, going well beyond the usual standards.

Most recently Gramazio & Kohler used this technology to design the Swiss pavilion at the last Architectural Biennale in Venice, presenting an impressive, threefold curvilinear new interpretation of a traditional brick building.

With Architonic's Concept Space II Gramazio & Kohler are now providing a further example of this special focal point of their research – additive production. In comparison to the more widely spread subtractive process which is connected with digitally controlled milling, this technology avoids serious wear and tear on the part of the material.

In the design of the Architonic Concept Space II design methods and production process run counter to each other in that they are at the same time subtractive and additive. The forms are digitally »eroded« from simple cubes using subtractive logic, with the necessary parameters such as statics and functional spaces being integrated in the calculations. A conventional industrial robot then additively assembles and glues variously sized full-scale segments to form the shell of the structure. The result is a fascinating, three-dimensional »pixel landscape« which does not try to conceal its digital origins.