Informazioni su Nanai

MAGGIORI INFORMAZIONI SU NANAI

Journey through time

nanai – leather in an unprecedented quality

1979 A vision is born

Rudolf Laschinger, with his roots in the salmon business, establishes a small smokehouse in the Bavarian forest. A bold entrepreneur with the right touch and business acumen, he expands the smokehouse over the years into a global fish cannery.

1985 A company takes off

Laschinger GmbH is founded in Bischofsmais, Bavaria, as the first company to import and process salmon on a grand scale. It successfully takes this luxury item, salmon, and turns it into high quality merchandise for the average consumer. Within a short time, Laschinger manages to skillfully boost its production capacity, while its environmentfriendly farming techniques earn it Naturland’s certification for organic salmon. This event spawns what is now the successful subsidiary nanai.

2005 A legacy is rediscovered

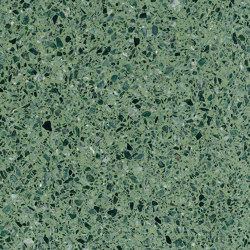

The idea that salmon skin should be higher up the value chain serves as the inspiration for using an environment-friendly industrial process to turn salmon skin into premium quality leather. Research identifies a distinctive method used by the Nanai folk for tanning fish skins, a form of art bearing great significance over millennia for this indigenous group in Eastern Siberia. Clearly, one cannot let such a unique form of art disappear into oblivion. A host of technical tanning specialists from Bischofsmais work for years with the Nanai folk. They jointly devise the right formula and reconstruct the tanning process handed down for generations.

2005/06 A pioneering feat creates nanai leather

Trials are conducted with tanners around the world, but none delivers acceptable results. Following numerous tests, the process is optimized in an in-house laboratory and scaled up to an industrial level. nanai leather now undergoes a totally new, environmentfriendly. multi-stage process. Years of research and highly advanced technologies help retain the pigmentation and unique texture of the salmon skin. This sows the seed for the birth of the company nanai.

2006 The vision of self-manufactured leather becomes reality

Salmo Leather GmbH is founded, and professional distribution of nanai leather commences. Holger Hain, a shareholder, takes the helm as the firm’s Managing Director. From 2003 through 2008, he is simultaneously a shareholder and MD of Laschinger GmbH, responsible for the finance and human resources departments.

2007 A solid merger

Europe’s leading salmon curing establishments merge: Laschinger GmbH of Bischofsmais and Morpol S.A. of Uska, Poland. Their goal is to reposition themselves and win market share in the competitive European and global arenas. Also, they aim to utilize valuable synergies, combine innovation capabilities, boost on-time deliveries, and raise the quality of raw materials. After-merger ownership: a 75% share is retained by the former shareholders of Laschinger GmbH. The remaining 25% is held by the merged entity, Laschinger GmbH / Morpol S.A., which assures supply of the desired raw material.

2007 Quality par excellence

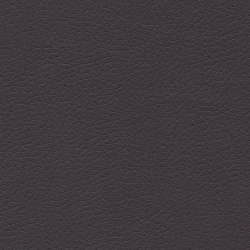

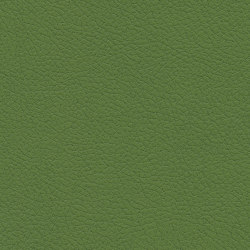

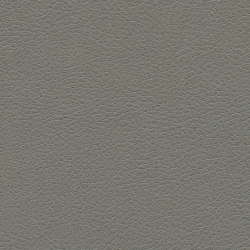

A stringent quality assurance program is launched to ensure compliance with the DIN standard for leather. A salmon skin has now moved up the value chain to become nanai leather. This leather par excellence is certified by FILK (Freiberg Research Institute for Leather and Synthetics). Due to the premium quality raw skins used, the leather fulfills all relevant manufacturing standards for fashion, accessories, interiors, and furniture. These unsurpassed base properties result in nanai leather with lasting superior comfort and low abrasion. The leather is light, yet tear-proof. It is thin, yet robust. It is multipurpose and ideal for a broad range of merchandise and applications.

2007 Premium quality leather

As the sole German producer of nanai leather in the sector with a chrome-free tanning process, it was necessary for nanai to convert the formula into an industrial process. nanai leather is exotic and elegant. Yet, in contrast to leathers from endangered species, one can enjoy it in many forms without a guilty conscience. Additional certifications confirm that nanai leather is especially hypoallergenic. It fulfills all significant standards, guidelines, and material requirements. Compared with conventional leathers of equivalent thickness, it is superior in terms of its fading resistance, rub fastness, and color fastness.

Certifications:

Hypo-allergenicity / Rub fastness / pH value / Finish adhesion / Flexing endurance /

Water spotting resistance / Dry cleaning / Tensile strength / Tear strength / Stitch tear

strength / Fat content (dichloromethane extract) / Tanning residues / Shrinkage

temperature / Fading resistance / Abrasion resistance

2008 Initial samples are released

The design and production of two sample collections (accessories) named Square and Girlande is initiated. The material is slated for testing during production and for quality. Custom furniture is also manufactured for connoisseurs.

End of 2008 Market launch & distribution

nanai is ready for the market. The distribution network is organized from Bischofsmais, employing local staff. Plans are to exhibit at the APLF in Hong Kong and New Delhi, and at Lineapelle Bologna and Le Cuir a Paris. Collaboration is initiated with the Esmod School of Fashion to open the doors for presenting other innovative merchandise and samples of nanai leather at exhibitions. Since its founding, the workforce at the nanai head office in Bischofsmais, Bavaria, has grown to 40 persons.

2009 nanai in the fashion world

nanai cooperates with the famous young fashion designer duo from Berlin, mongrels in common, at the Mercedes-Benz Fashion Week Spring/Summer 2010. The duo uses the unique nanai leather for its collection called “A Siberian Icelandic Marriage.” mongrels in common is excited about the innovative nature and philosophy of nanai leather and is creating an exceptional, premium quality collection. Christine Pluess remarks, “We are very happy to be working with nanai. We were thrilled about the material after just one look and see great potential in this collaboration.”

01-2010

The successful partnership between nanai and mongrels in common is continued for the 2010/2011 season. nanai again supports the Berlin fashion label during the Mercedes- Benz Fashion Week Berlin in January 2010. Going “new ways and realising one’s visions, these are qualities that connect nanai and mongrels in common”, says Holger Hain, managing director of nanai.

01-2010

The successful designer Michael Michalsky uses the special leather from nanai for his autumn/winter collection 2010/2011. Cleverly sewn together to multi-coloured pieces, the leather is used for hems in various collection parts. Also his bag line “MCM by MICHALSKY”, created in cooperation with MCM, sees the integration of nanai leather in several models. Chrissie Morris uses the leather to set exotic accents in her ladies’ shoes designed exclusively for MICHALSKY. The men’s shoes are a particular highlight, which are entirely made of nanai leather.

02-2010 Nanai leather finding application in vehicle furnishing

The extraordinary nanai leather also convinces BMW and can be ordered by special request. The BMW X6M is the first vehicle worldwide to be furnished with this leather. The moulding and various applications, usually made of plastic, wood or piano lacquer, are individually crafted with nanai leather. A very lively design results from using this natural leather.

2010 Outlook

The shoe manufacturer Ludwig Reiter plans to introduce nanai leather shoes to the market in 2010, as well as Pollini, one of the most famous Italian manufacturers of high quality bags and shoes. In addition, many exciting collaborations with well-known designers and companies from areas such as interior, fashion, accessories and jewellery are already being planned and will attract lots of attention in the coming months.

Journey through time

nanai – leather in an unprecedented quality

1979 A vision is born

Rudolf Laschinger, with his roots in the salmon business, establishes a small smokehouse in the Bavarian forest. A bold entrepreneur with the right touch and business acumen, he expands the smokehouse over the years into a global fish cannery.

1985 A company takes off

Laschinger GmbH is founded in Bischofsmais, Bavaria, as the first company to import and process salmon on a grand scale. It successfully takes this luxury item, salmon, and turns it into high quality merchandise for the average consumer. Within a short time, Laschinger manages to skillfully boost its production capacity, while its environmentfriendly farming techniques earn it Naturland’s certification for organic salmon. This event spawns what is now the successful subsidiary nanai.

2005 A legacy is rediscovered

The idea that salmon skin should be higher up the value chain serves as the inspiration for using an environment-friendly industrial process to turn salmon skin into premium quality leather. Research identifies a distinctive method used by the Nanai folk for tanning fish skins, a form of art bearing great significance over millennia for this indigenous group in Eastern Siberia. Clearly, one cannot let such a unique form of art disappear into oblivion. A host of technical tanning specialists from Bischofsmais work for years with the Nanai folk. They jointly devise the right formula and reconstruct the tanning process handed down for generations.

2005/06 A pioneering feat creates nanai leather

Trials are conducted with tanners around the world, but none delivers acceptable results. Following numerous tests, the process is optimized in an in-house laboratory and scaled up to an industrial level. nanai leather now undergoes a totally new, environmentfriendly. multi-stage process. Years of research and highly advanced technologies help retain the pigmentation and unique texture of the salmon skin. This sows the seed for the birth of the company nanai.

2006 The vision of self-manufactured leather becomes reality

Salmo Leather GmbH is founded, and professional distribution of nanai leather commences. Holger Hain, a shareholder, takes the helm as the firm’s Managing Director. From 2003 through 2008, he is simultaneously a shareholder and MD of Laschinger GmbH, responsible for the finance and human resources departments.

2007 A solid merger

Europe’s leading salmon curing establishments merge: Laschinger GmbH of Bischofsmais and Morpol S.A. of Uska, Poland. Their goal is to reposition themselves and win market share in the competitive European and global arenas. Also, they aim to utilize valuable synergies, combine innovation capabilities, boost on-time deliveries, and raise the quality of raw materials. After-merger ownership: a 75% share is retained by the former shareholders of Laschinger GmbH. The remaining 25% is held by the merged entity, Laschinger GmbH / Morpol S.A., which assures supply of the desired raw material.

2007 Quality par excellence

A stringent quality assurance program is launched to ensure compliance with the DIN standard for leather. A salmon skin has now moved up the value chain to become nanai leather. This leather par excellence is certified by FILK (Freiberg Research Institute for Leather and Synthetics). Due to the premium quality raw skins used, the leather fulfills all relevant manufacturing standards for fashion, accessories, interiors, and furniture. These unsurpassed base properties result in nanai leather with lasting superior comfort and low abrasion. The leather is light, yet tear-proof. It is thin, yet robust. It is multipurpose and ideal for a broad range of merchandise and applications.

2007 Premium quality leather

As the sole German producer of nanai leather in the sector with a chrome-free tanning process, it was necessary for nanai to convert the formula into an industrial process. nanai leather is exotic and elegant. Yet, in contrast to leathers from endangered species, one can enjoy it in many forms without a guilty conscience. Additional certifications confirm that nanai leather is especially hypoallergenic. It fulfills all significant standards, guidelines, and material requirements. Compared with conventional leathers of equivalent thickness, it is superior in terms of its fading resistance, rub fastness, and color fastness.

Certifications:

Hypo-allergenicity / Rub fastness / pH value / Finish adhesion / Flexing endurance /

Water spotting resistance / Dry cleaning / Tensile strength / Tear strength / Stitch tear

strength / Fat content (dichloromethane extract) / Tanning residues / Shrinkage

temperature / Fading resistance / Abrasion resistance

2008 Initial samples are released

The design and production of two sample collections (accessories) named Square and Girlande is initiated. The material is slated for testing during production and for quality. Custom furniture is also manufactured for connoisseurs.

End of 2008 Market launch & distribution

nanai is ready for the market. The distribution network is organized from Bischofsmais, employing local staff. Plans are to exhibit at the APLF in Hong Kong and New Delhi, and at Lineapelle Bologna and Le Cuir a Paris. Collaboration is initiated with the Esmod School of Fashion to open the doors for presenting other innovative merchandise and samples of nanai leather at exhibitions. Since its founding, the workforce at the nanai head office in Bischofsmais, Bavaria, has grown to 40 persons.

2009 nanai in the fashion world

nanai cooperates with the famous young fashion designer duo from Berlin, mongrels in common, at the Mercedes-Benz Fashion Week Spring/Summer 2010. The duo uses the unique nanai leather for its collection called “A Siberian Icelandic Marriage.” mongrels in common is excited about the innovative nature and philosophy of nanai leather and is creating an exceptional, premium quality collection. Christine Pluess remarks, “We are very happy to be working with nanai. We were thrilled about the material after just one look and see great potential in this collaboration.”

01-2010

The successful partnership between nanai and mongrels in common is continued for the 2010/2011 season. nanai again supports the Berlin fashion label during the Mercedes- Benz Fashion Week Berlin in January 2010. Going “new ways and realising one’s visions, these are qualities that connect nanai and mongrels in common”, says Holger Hain, managing director of nanai.

01-2010

The successful designer Michael Michalsky uses the special leather from nanai for his autumn/winter collection 2010/2011. Cleverly sewn together to multi-coloured pieces, the leather is used for hems in various collection parts. Also his bag line “MCM by MICHALSKY”, created in cooperation with MCM, sees the integration of nanai leather in several models. Chrissie Morris uses the leather to set exotic accents in her ladies’ shoes designed exclusively for MICHALSKY. The men’s shoes are a particular highlight, which are entirely made of nanai leather.

02-2010 Nanai leather finding application in vehicle furnishing

The extraordinary nanai leather also convinces BMW and can be ordered by special request. The BMW X6M is the first vehicle worldwide to be furnished with this leather. The moulding and various applications, usually made of plastic, wood or piano lacquer, are individually crafted with nanai leather. A very lively design results from using this natural leather.

2010 Outlook

The shoe manufacturer Ludwig Reiter plans to introduce nanai leather shoes to the market in 2010, as well as Pollini, one of the most famous Italian manufacturers of high quality bags and shoes. In addition, many exciting collaborations with well-known designers and companies from areas such as interior, fashion, accessories and jewellery are already being planned and will attract lots of attention in the coming months.

MAGGIORI INFORMAZIONI SU NANAI