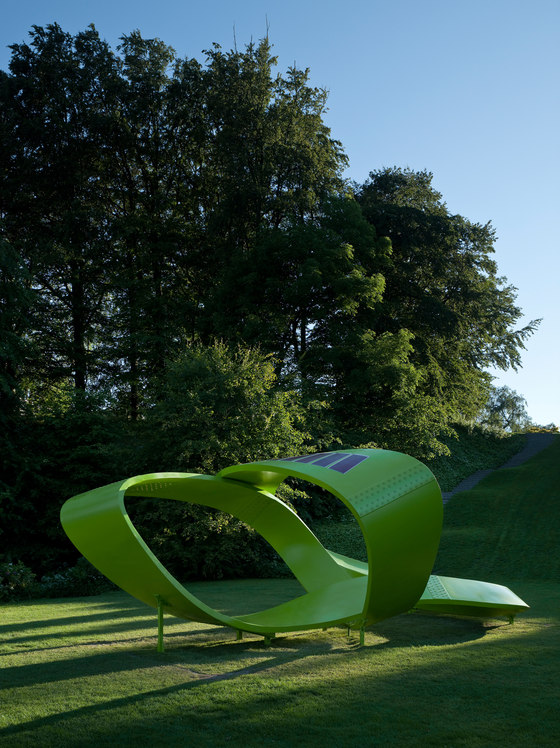

As part of the ‘Green Architecture for the Future’ architectural exhibition, the Louisiana Museum of Modern Art invited 3XN to design a pavilion demonstrating cutting edge possibilities with sustainable and intelligent materials.

The Pavilion has given us the opportunity to showcase the possibilities which exist in building with sustainable and intelligent materials. Our objective has been to show that Green Architecture can be dynamic and active. We often think that we need to minimize use of resources at all costs. Instead of focusing on consuming the least amount of energy, we need to focus on producing and using energy and materials in a more intelligent way than is the case today, says Kim Herforth Nielsen, Founder and Principal Architect of 3XN.

The vision of the project has been to build with biodegradable and energy-generating materials, creating an energy-self-sufficient architecture that also can be part of, and be decomposed in, the biological cycle after use.

New Combinations

Sustainable solutions are often associated with architectural compromises. For this reason it has been important to show that sustainable materials have legitimate future potential in the building industry - practically as well as aesthetically. Building with intelligent and biological materials with a refined finish, in a complex mode of expression, pushes the limit in people’s minds of what is obtainable with sustainable materials today.

Sustainable Materials

Well-known synthetic products have been substituted with biological and reusable materials. For the outer shell of the sculpture, glass fiber composites have been substituted with a bio composite from flax fibers cast in biological resin. Cork sheets replace polystyrene foam for the inner core.

Intelligent Materials

For the sculpture, the newest built-in technologies have been applied creating a dynamic and green architecture. On the top face of the pavilion, 1mm flexible solar cells are placed. The cells are cast in thin film making them applicable to double curved surfaces. Piezoelectric materials that generate an electric current from the weight of the visitors are laid in the floor. Combined, this makes the sculpture self-sufficient with energy to power the integrated LED lights.

Why not build dynamic buildings that harvest energy from the surroundings?

The pavilion has a coating of nanoparticles that makes the surfaces self-cleaning. Due to a hydrophilic nanostructure, rain water is dispersed beneath the dirt on the surface, leaving it cleaner. A second coating adds air cleaning properties to the pavilion. A chemical process called photocatalysis decomposes up to 70 percent of pollutants from industrial smog. Documentation shows that the air quality is improved within an 8-feet radius of air cleaning surfaces.

The pavilion retains heat by using phase changing materials. Heated by the sun, the material retains the energy, releasing it again when the temperature drops. At exactly 23 degrees Celsius, the material changes from a solid to a liquid form. When the temperature rises, the material absorbs energy and is liquefied. When the temperature drops, it solidifies and releases energy. In other words, the surface of the pavilion remains cooler when the temperature of the surroundings is rising, and vice versa. It is estimated that phase changing materials can cut costs with 10 to 15 percent on heating and cooling of buildings.

Digital Design and Production

The design of the pavilion is optimized according to function and material consumption. The mode of expression and material consumption is digitally designed to meet the exact needs, i.e. 14 layers of fiber and 84mm of cork are specifically designed to meet the dynamic forces arising from wind load and the load from people walking on the surface. Adapting the new sustainable materials to the digital modes of production has been a huge challenge in itself. The learning process of substituting synthetic materials for biological counterparts has spanned the entire project phase, revealing many obstacles and given rise to new innovations on the way.

Process

The Louisiana Pavilion is a joint venture of 20 companies. Due to a tight 4-month schedule and a high level of ambition, it was essential that all parties involved took ownership of the project; that concept, design, innovation and production were all in play at the same time during the development phase - a process where several project phases melted into one. This called for close, integrated cooperation between everyone involved.

Kim Herforth Nielsen, Kasper Guldager Jørgensen, Rasmus Møller, Christian Bundegaard, Stian Lenes and Morten Myrup