Fotografo: Ditz Fejer

In a universe of multiple new properties, Chapman Taylor Architects have managed to stand out with their concept of an unusual building shell made of concrete and copper.

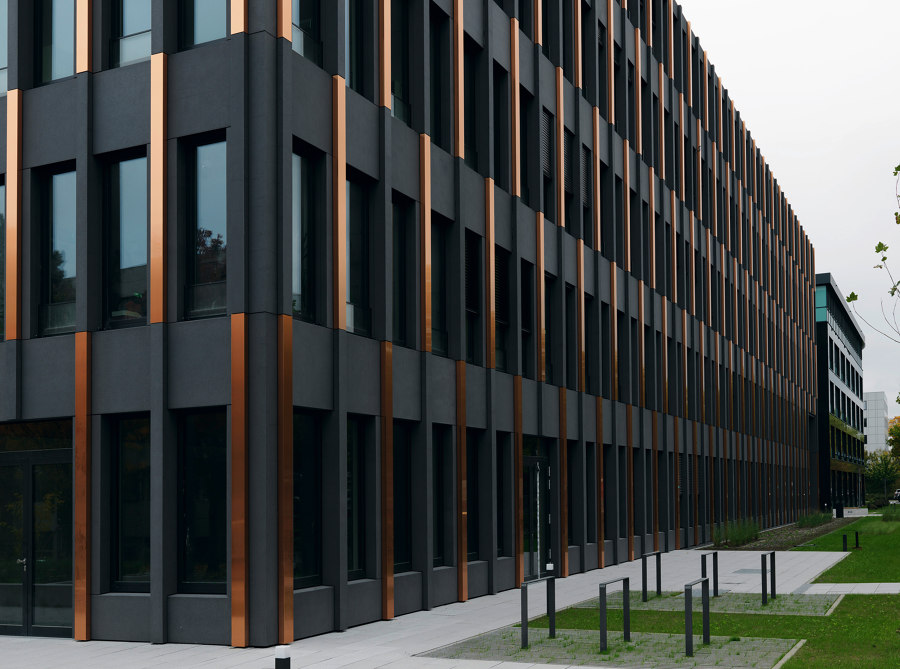

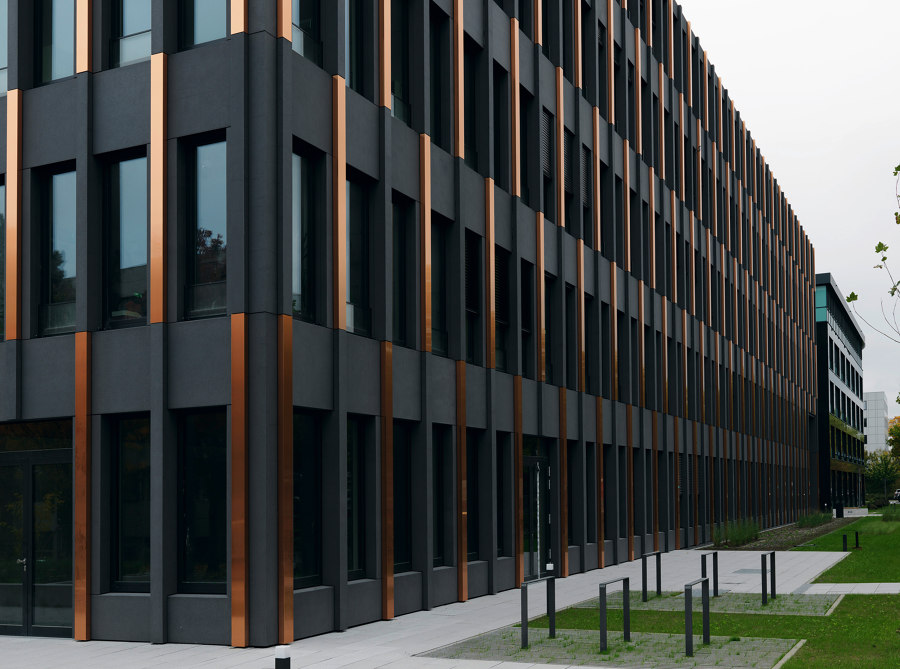

At the German Aerospace Centre’s offices, you can allow yourself to conjure up an association of space and universe. Coincidentally, the graceful space black of the facade appears to have been tailor-made for the main tenant of the office complex on Godesberger Allee in Bonn. On the other hand, the sharp-edged moulded parts made of glassfibre reinforced concrete were individually manufactured for the needs of the building’s architecture. formparts.fab in liquid black from the Austrian concrete manufacturer Rieder lends the facade its striking look in combination with elements of copper.

The building, which was completed in 2020 on behalf of the Munich real estate company Fondara, was planned by Chapman Taylor Architects and cleverly embedded into the existing structure. With imaginative materials and creative interpretation of colours, the new building blends calmly with the side building, which is also dark. The rough feel of the concrete elements and the subtle sheen of the copper elements give the complex something sublime and timeless. Overall, Chapman Taylor managed to achieve a balancing act between functionality and maximum space utilisation using sophisticated architectural details. Concrete and copper pilaster strips provide the office complex with an attractive relief on an otherwise straight facade.

“With Rieder’s formparts.fab, we found the perfect product for the monolithic facade design with a relief-like structure. The wide range of design options combined with the weight-saving, minimal material thickness was decisive here,” explains Hendrik Wirths – project manager at Chapman Taylor Architects in Düsseldorf. Chapman Taylor is an internationally renowned architecture and urban planning office with 17 independent offices in Europe, Asia, the Middle East and South America.

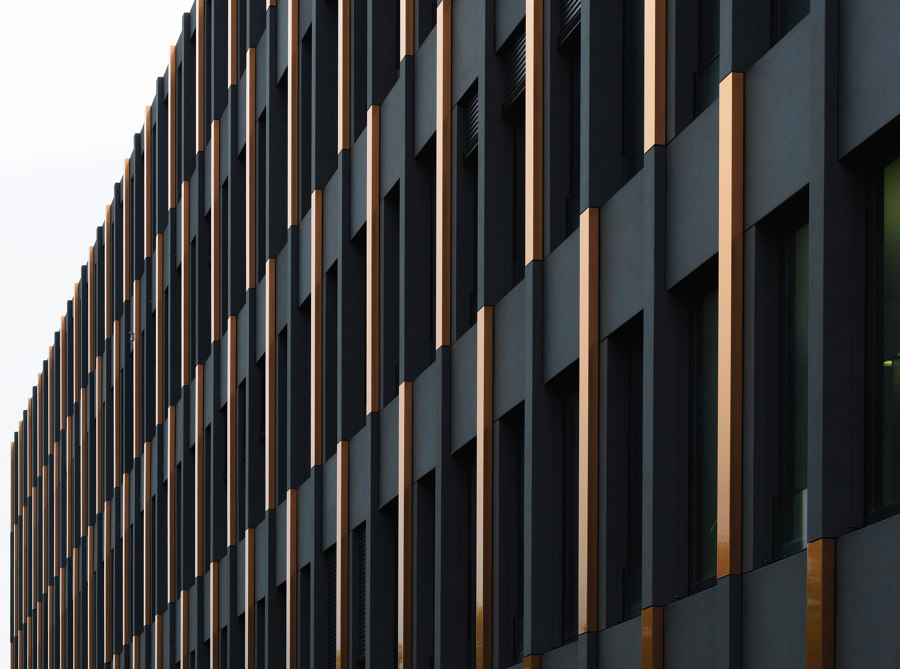

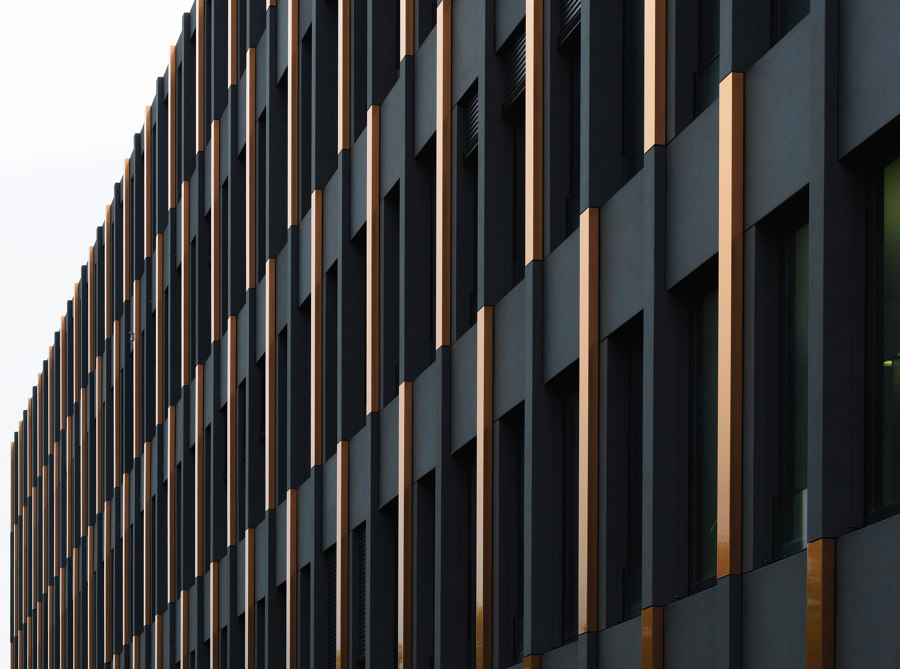

A network of concrete and copper

“Floor-height copper-coloured elements are also arranged in every second axis field. These jump from floor to floor via one field each and subsequently form a grid-like network structure.” By using Rieder’s formparts.fab moulded parts, the architects were able to achieve an extraordinary tactile effect and in addition, combine a range of technical advantages with visual specifications. The elements made of 13 mm thin glassfibre reinforced concrete can be produced individually and tailor-made in several colours, surfaces, textures and shapes up to seven metres long. This enabled an effortless transition to the copper elements. The contrast in the colour scheme and the tactile difference between the shiny copper pilaster strips and the rough elements made of Rieder’s glassfibre reinforced concrete in the ferro surface form, create an additional arc of tension in the actually simple basic structure of the outer shell. With their cleverly chosen structure, Chapman Taylor lost neither window surface nor space in favour of the facade design. The combination of colours and materials and the division of the pilaster strips on the axis create an exciting, striking image.

formparts from Rieder: a popular solution for current architectural trends

formparts.fab from Rieder are part of the wide range of solutions that experts in sustainable building envelopes can offer planners and builders when it comes to concrete facades. The sharp-edged formparts.fab are put together from several elements and are therefore comparatively easy and simple to use during installation. A variety of colours and surfaces and a multitude of different shapes and lengths help planners to implement optimal solutions. The shaped elements can be perfectly combined with the flat concrete skin panels. Architecturally demanding facades with ecological and economic advantages can therefore be easily implemented.

Architect

Chapman Taylor

Fotografo: Ditz Fejer

Fotografo: Ditz Fejer

Fotografo: Ditz Fejer

Fotografo: Ditz Fejer