CNC carpentry: the 'selfsupportingframework'

Scritto da Nora Schmidt

Berlin, Germania

06.10.10

Recently, carpentry-oriented joinery has been enjoying a renaissance thanks to the increased use of CNC-driven manufacturing techniques – even connecting parts can be produced in a number of geometric variations and cost efficiently at that.

Two students working on load-bearing systems in the architecture department at Kassel University, Mischa Proll and Andreas Günther, have taken advantage of the wide range of design techniques available and breathed new life into a one-hundred-year-old construction concept.

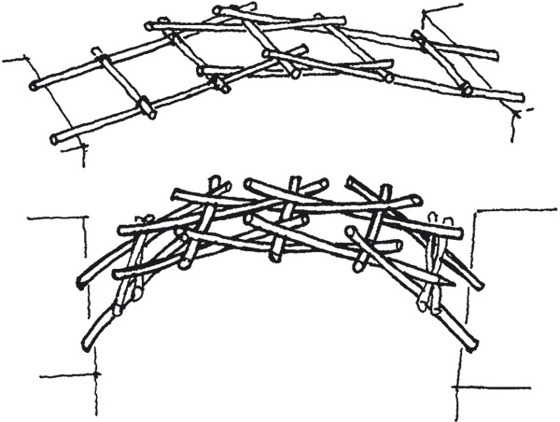

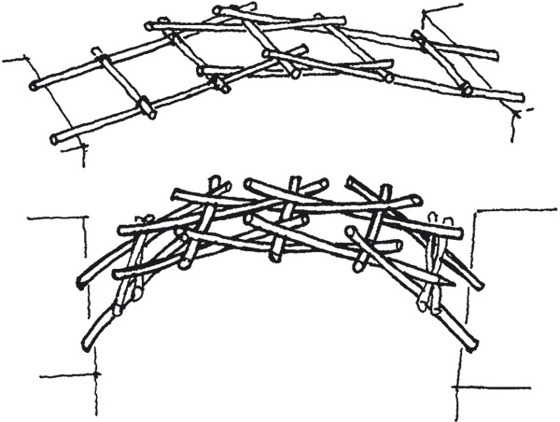

The traditional reziprocal frame consists of short wooden joists, whose ends are carpentry-joined to a surface structure. With consistant types of profiles, lengths of elements and positions of the knots on the axises, a dome shape is created. The first documenting of such a framework, also called a „mandala roof“, dates back to the 12th century, according to the students' research, when a Buddhist monk by the name of Chogen created designs for temples, whose influence can still be seen today in the architecture of domes in China and Japan.

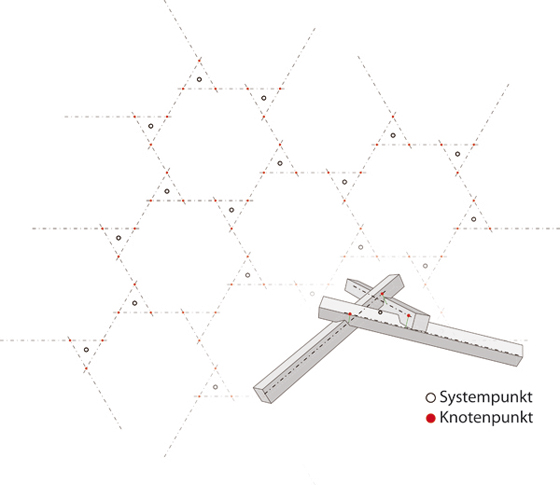

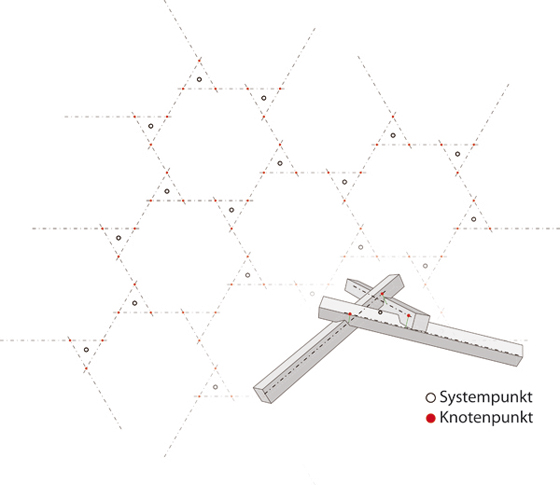

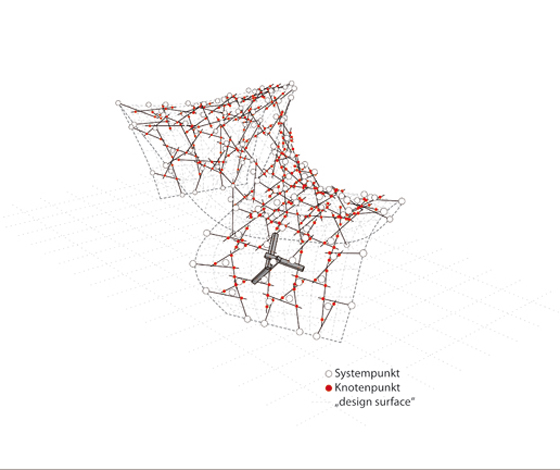

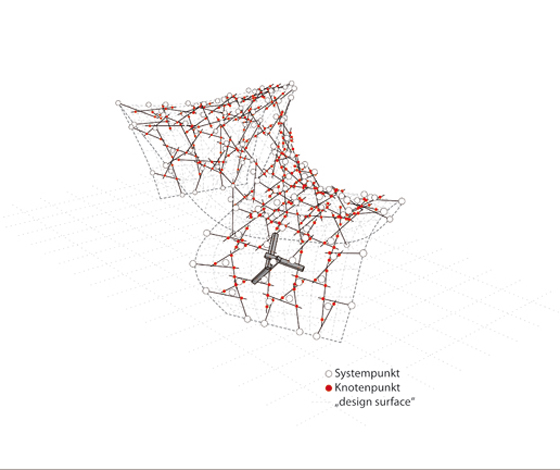

The variation of individual parameters, for instance changing the join between two elements, leads to a change in all the other subsequent joins. Customising the length of battens and where they meet turns a static system into a variable one, allowing free geometric forms to be created. Having realised this, Mischa Proll and Andreas Günther developed a calculation principle, which allows the construction of almost randomly formed, highly stable surfaces – proportionally independent of the actual density of the system.

'Reciprocal frame' bridge from the Codex Madrid by Leonardo da Vinci

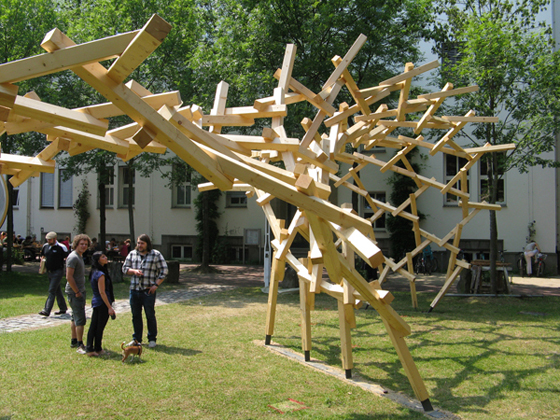

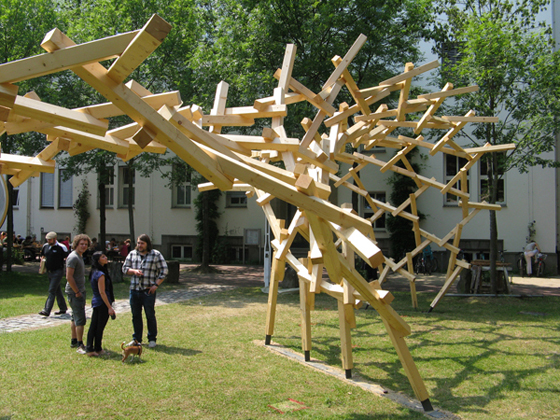

Working with a team of 11 apprentices from the Bundes-Bildungszentrum des Zimmererhandwerks in Kassel, the first test structure, consisting of 180 timber elements, was recently completed on the university campus. The architects-in-waiting pulled it off in style, creating a build that proves rather handsomely the creative freedom the system offers.

"The design surface starts on its short side with an arch, which then comes down in the middle section on one of its outer edges, like a curved wall, which is then repeated at the end of the surface, closing off the pavilion. In the middle section, the design surface twists, a bit like a Mobius strip, its inner surface becoming its outer. So the top side of the first arch becomes the underside of the second,“ explains Mischa Proll, who designed the pavilion as part of his degree work.

Each piece of timber has an identical profile, but is, due to ist different cuts, at the same time unique

Each piece of timber has an identical profile, but is, due to ist different cuts, at the same time unique

×Construction of the 'selfsupportingframework' on the campus of the Kassel University

The construction, comprising 180 wooden elements, is 13.5 metres long and 5 metres wide

The Kassel 'selfsupportingframework' demonstrates not only what computer-aided architecture can do in terms of design, but it also shows the applicability of wood as an renewable building material in the creation of highly complex geometric forms.

Project team:

Universität Kassel Fachbereich Architektur

Fachgebiet Tragkonstruktion

Fachgebiet Digitale Entwurfstechniken

Sachgebite Vermessung

Bundesbildungszentrum des Zimmerergewerbes

Sponsors:

SFS intec , Stahlbau Lamparter, Säge- und Hobelwerk Oberweser.